PCBs (printed circuit boards) and PCBA ( Printed Circuit Board Assembly) are both essential components of electronic devices. Both PCBs and PCBA refer to individual pieces within a larger system, so it’s important to understand the difference between these two terms. Encapsulated in these acronyms are details about each assembly’s role in the finished product. Understanding how these parts work together can help you make informed decisions when choosing suppliers or services for your next project. Read on to learn more about the differences between a PCB and a PCBA, as well as additional details about each part and what they mean for your design process.

Printed Circuit Boards

A printed circuit board (PCB) is a sheet of fiberglass with copper foil (or copper-clad fiberglass) on one side. Wires are attached to the copper using soldering, and the assembly is then coated with a protective layer. The copper traces are called “conductive pathways” and are used to connect components and parts. The common shape is a square or rectangle. This makes it easy to design and manufacture PCBs. Circuits can be complicated and contain many parts and components. This is where PCBs come in. Each type of electronic device uses a PCB for its main circuit board. From smartphones and laptops to medical devices and space exploration equipment, PCBs are at the core of all modern technology.

where are pcb used?

PCBs are used in many devices and systems, including but not limited to – data processing equipment, communications equipment, radio equipment, computers, semiconductor devices, magnetic and optical recording devices, and electro-mechanical systems such as automobiles, air traffic control systems and industrial robots.

What is PCB made of?

The base material used in PCBs is usually fiberglass. Other materials include thermoplastic and thermosetting resins, epoxy and polyimide. Copper foil is generally used for the conductive layer. Fiberglass is often chosen as the base material because of its low cost and its ability to resist corrosion. This material also has excellent strength and heat resistance, which makes it a great choice for high-temperature applications.

Types of PCBA

There are several assembly methods, including manual, SMT, and Through-Hole.

Manual Assembly:

This type of assembly is done by hand and is very labor-intensive. This method is typically done for small production runs with low volumes. Manual assembly is often used for prototypes.

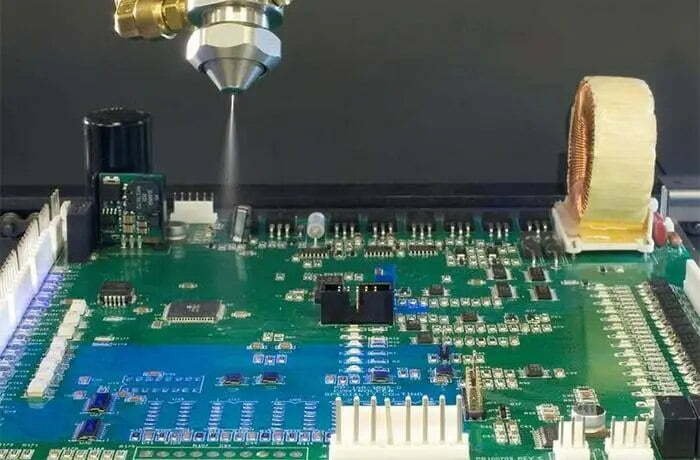

SMT Assembly:

SMT stands for surface-mount technology. This method uses machines to accurately place components on the PCB.

Through-Hole Assembly:

This method involves components that are placed on the PCB, as well as wires that are fed through holes drilled in the PCB.

What is a PCBA used for?

A printed circuit board assembly (PCBA) is a fully assembled printed circuit board. A PCBA is complete and ready to be connected to other systems and other boards. After SMT machines or manual assembly is done, components are placed on the PCB and then soldered or connected to them. The connections are then covered with a protective layer. This fully assembled PCBA (also called a “bare board”) can be directly connected to other boards or systems to complete an entire system.

How PCBA is manufactured?

PCBA is a fully assembled printed circuit board that is ready to be used. All of the components have been soldered to the board and a protective coating has been applied. The basic steps that are involved in manufacturing a PCBA are as follows:

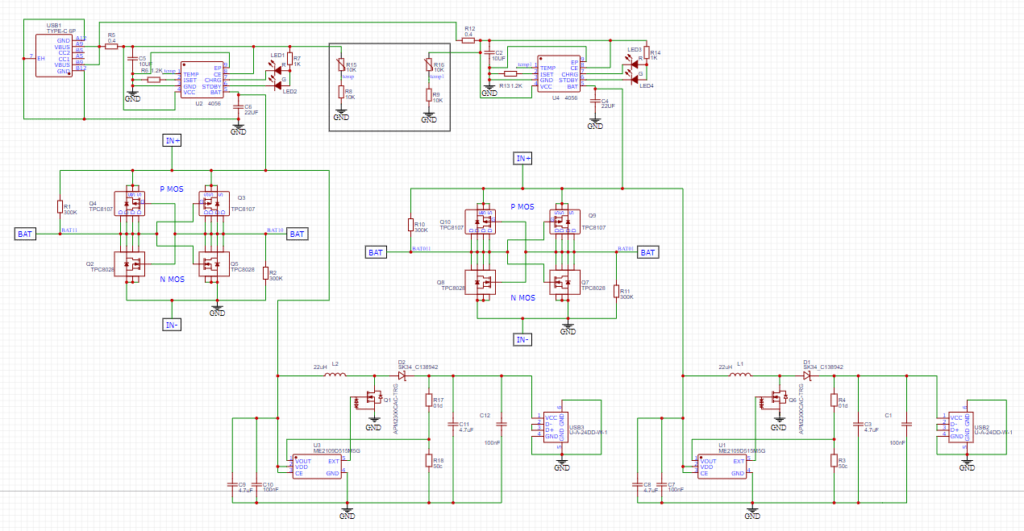

- PCB Design:

This step is also known as schematic design. In this step, designers determine which components will be part of the circuit, as well as the connections between them.

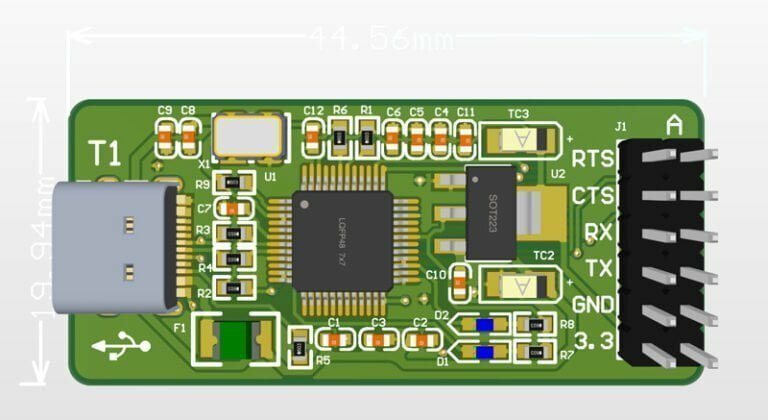

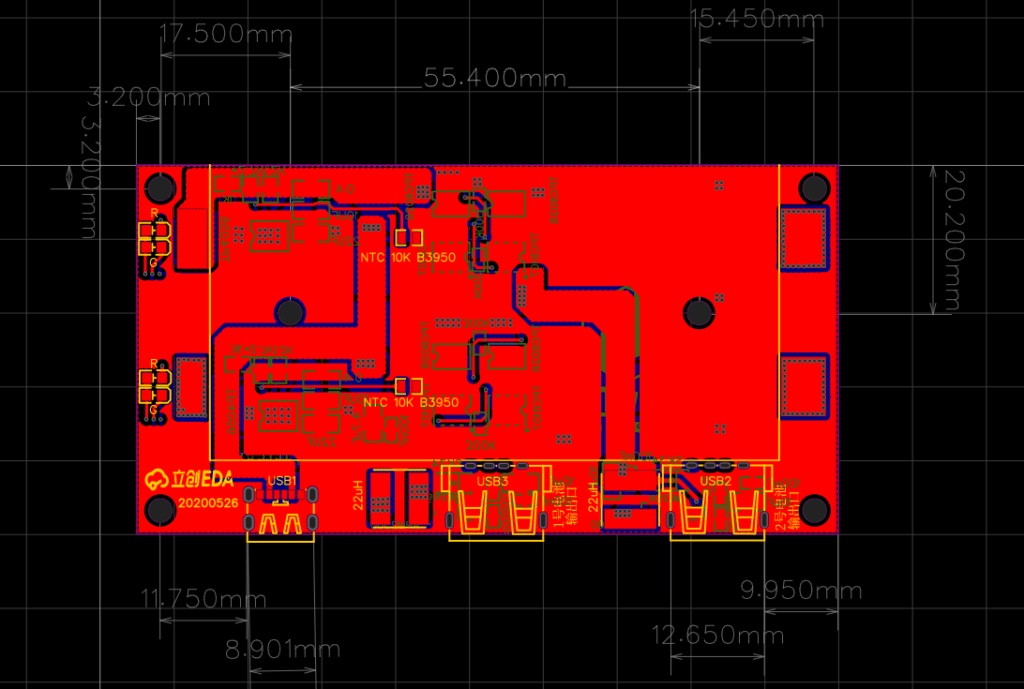

- PCB Layout:

The next step is PCB layout. This process involves designing and creating the physical board. The layout determines where components will be placed on the PCB.

- PCB Fabrication:

In the fabrication step, the circuit design created in the previous steps is implemented. This includes creating the printed circuit board.

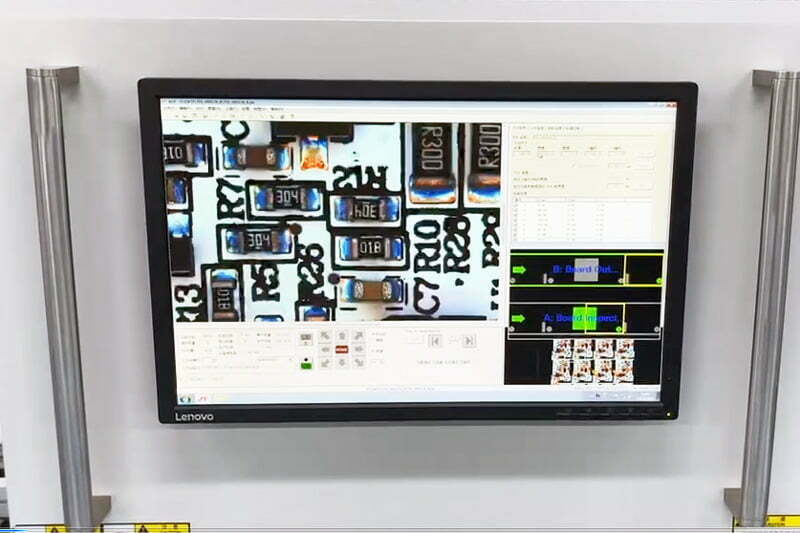

- PCB Testing:

The testing phase confirms that the design works as intended. Designers use test equipment and software to check that the board functions properly.

What Files are Needed to Manufacture a PCBA

If you are producing a PCB, you will need to create a schematic. If you are producing a PCBA, you will need a bill of materials (BOM). A schematic diagram is a visual way to show what components are being used, where they are placed and how they are connected. It is a helpful tool for designers to communicate their ideas. A BOM lists all of the components used in a PCB as well as their quantities. The BOM is essential if you need to order more parts or if you want to find a supplier.

PCB vs. PCBA: Which One is Right for You?

PCBs and PCBA are both essential components of electronic devices. The difference between a PCB and a PCBA is that a PCB is an individual piece within a larger system, whereas a PCBA is a fully assembled PCB. We can say that PCBs play the role of the brain of the system, while the PCBA plays the role of the body of the system. Designers use PCBA to connect all of the components that are designed on the PCB. This can be compared to a fully assembled computer.

The PCB is the motherboard of the computer, while the PCBA is the computer itself with all of its other parts connected. A PCB can be used independently as long as it has all of its components connected. But not vice versa. A fully assembled PCB can be used as a standalone system. A PCB is used to make custom circuits, especially one-off circuits for a particular application.

How to Choose a PCBA Manufacturer in China?

A printed circuit board assembly (PCBA) is a fully assembled printed circuit board. A PCBA is ready to be used and can be directly connected to other boards or systems to complete an entire system. If you are manufacturing an electronic product, you will need to source a PCBA manufacturer. Finding the right manufacturer can be challenging. That’s why you should start with these four factors before making a decision.

-Industry Experiences

First and foremost, you will want to make sure that the company you choose has experience manufacturing your particular product.

-PCBA design approved tested

This is the most important factor to be considered while getting a PCBA manufacturer. The entire success of your product depends on the quality of the PCBA circuit design. To make sure that the PCBA circuit design is thoroughly tested, you can hire a service provider who will conduct a due diligence of the PCBA manufacturer.

As a manufacturer you have to make sure that the PCBA design has been tested and validated. The moment you go with a PCBA manufacturer and they have not tested their design, you are taking a huge risk of losing your entire business once the finished product is delivered to you.

-Certifications & Licenses

Next, you will want to make sure that the manufacturer you choose has the technical expertise to manufacture the functionality you require. Depending on the product you are manufacturing, you will want to make sure that the manufacturer you choose has the right certifications and licenses to be operating in your country.

Checking components

Make sure that the components you are ordering are the ones you actually need. Sometimes suppliers will mix up components and send you the wrong ones. Double-check before you order any new components. You don’t want to order the wrong part and have to order it again. Make sure that your suppliers have a return policy if you send back the wrong components.

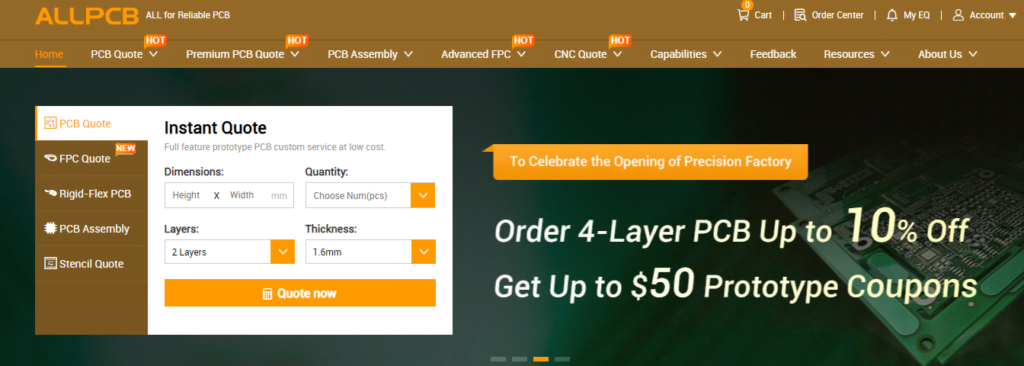

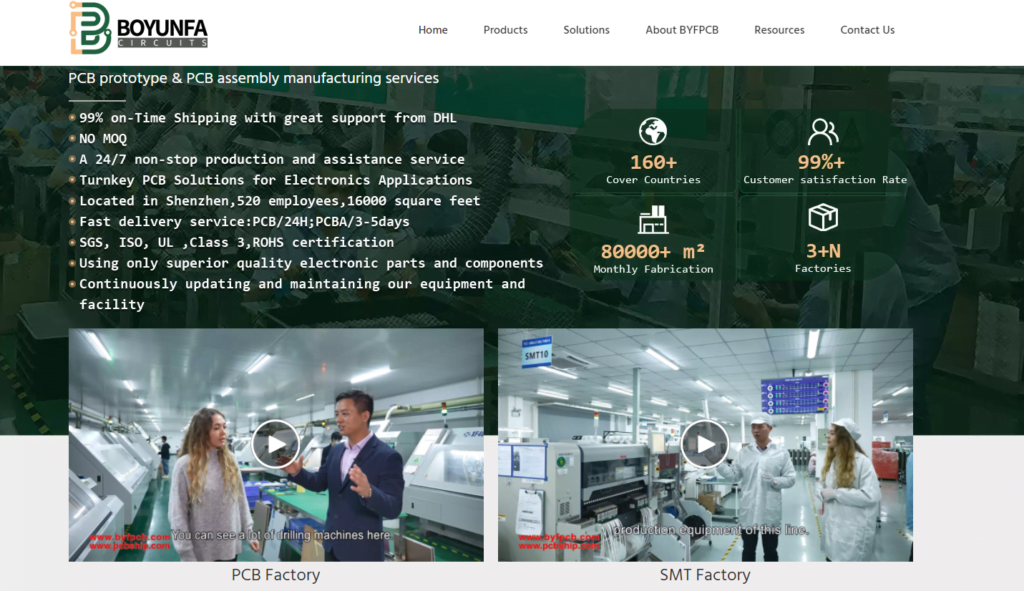

Trustworthy PCBA Manufacturer in China

A trustworthy PCBA manufacturer can meet your design and quality expectations. This means that they can produce a PCBA that is a good fit for your product. Moreover, they have experience working with customers from all industries, including yours. This can help you to save time and money since you won’t have to re-design the PCB to fit the product. China is becoming a global leader in the manufacturing industry, including PCB Assembly. Chinese manufacturers are increasingly investing in new technologies and innovation. They are continuously improving their product quality.

ALL PCB

Bo Yun Fa Technology Co.,Ltd

Atech PCB