Professional BLDC Motor Development Services

About BLDC Motor

BLDC (Brushless DC) motors, also known as electronically commutated motors, are a type of synchronous motor that operates using direct current (DC) electricity. Unlike traditional brushed motors, BLDC motors use electronic commutation instead of brushes and a commutator to control the rotor’s movement. This design offers several advantages, including higher efficiency, longer lifespan, quieter operation, and reduced maintenance requirements. BLDC motors are widely used in various applications, including electric vehicles, industrial automation, HVAC systems, home appliances, and drones, due to their reliability, precise control, and energy efficiency.

Overview of BLDC Motor Solutions

Our BLDC (Brushless DC) motor solutions offer advanced and efficient solutions for various applications requiring precise motor control and high reliability.

Key features of our BLDC motor solutions include:

Efficiency

Our BLDC motors are designed for high efficiency, offering energy savings and reduced operating costs.

Reliability

With brushless design and advanced control algorithms, our BLDC motor solutions provide reliable operation and long lifespan, minimizing downtime and maintenance requirements.

Precision Control

Our BLDC motor solutions offer precise speed and torque control, making them suitable for applications requiring accurate motion control.

Compact Design

The compact and lightweight design of our BLDC motors allows for easy integration into space-constrained applications, without compromising performance.

Customization

We offer customizable BLDC motor solutions tailored to meet specific application requirements, including voltage, power rating, speed, and torque characteristics.

Types of BLDC Motor

Sensored BLDC Motor

BLDC motors with Hall sensors rely on sensors for rotor position data, offering reliable performance at lower speeds. While they provide accurate data for smooth rotation at lower speeds, they may experience delayed feedback at higher speeds.

Sensorless BLDC Motor

This type of motor does not use Hall sensors. Instead, the controller relies on the back electromotive force generated in the stator coils to calculate the rotor position. These types of brushless DC motors offer optimal performance at high speeds. They can also be used in high-temperature environments.

Single-phase BLDC Motor

The rotor used in single-phase brushless motors consists of a pair of north and south poles. The benefit is that the motor can initially achieve high rotational speeds. However, the performance of single-pole motors significantly decreases at lower speeds, thereby affecting rotational efficiency.

Three Phase BLDC Motor

Two-phase and three-phase brushless motors have multiple magnetic poles on the rotor, typically up to 12 or more. More poles provide smoother rotation but sacrifice speed. Thus, these motors are ideal for low-speed, high-torque applications.

In-runner BLDC Motor

An in-runner BLDC motor has the rotor inside, surrounded by the stator. Also known as internal-rotor brushless motors, they're smaller in diameter and have higher rotational speed than out-runner motors. They're ideal for compact, high-speed applications like RC vehicles, drones, and small electric appliances.

Out-runner BLDC Motor

The out-runner BLDC motor features a rotating outer casing around fixed internal components. It usually has more magnetic poles on the rotor, providing greater torque and smoother operation. It tend to have slower speeds, making them more suitable for low-speed, high-torque applications.

Square Wave BLDC Motor

Square wave driving is a straightforward method where electronic components switch on and off according to the rotor's position, altering the current direction in the stator coils for rotor rotation. This switching occurs six times per rotor rotation.

FOC BLDC Motor

Field-Oriented Control (FOC) BLDC motors offer precise control over motor speed and torque by aligning the magnetic field with the rotor position. They are ideal for applications requiring high performance, such as electric vehicles, robotics, and industrial automation.

Sinusoidal BLDC Motor

The sinusoidal wave driver operates by dynamically adjusting the voltage of the stator coils in a sinusoidal pattern, synchronized with the rotor's rotational angle. This method ensures smooth rotation by precisely timing the phases of the motor. Each phase experiences a slight delay to improve the performance.

Applications of BLDC Motor

The BLDC motor solutions are applicable in various fields, such as AGV / AMR applications, electric vehicle drive systems, industrial equipment, home appliances, drones, and the medical industry.

AGV / AMR

Brushless motors find applications in AGV/AMR designs, enabling battery-powered, compact, and lightweight equipment motion control. They offer the following advantages: compact structure, maintenance-free operation, and long lifespan. Precise control and positioning are achieved through brushless Hall angle sensing. With a wider speed range and greater torque, they provide smoother motion control.Drone / FPV

Brushless motors are used in the power unit of drones. Multiple brushless motors are typically installed on drones to drive propellers, generating thrust for takeoff, landing, hovering, and forward motion. They can increase the drone's flight speed and payload capacity. With compact structure and lightweight design, brushless motors offer significant advantages in stability and power conversion.Automatic

Brushless motors are increasingly being used in the automotive industry. In vehicles, brushless motors can serve as both generators and motors. As a generator, they charge the car battery and provide power to the vehicle. Compared to the traditional induction asynchronous motors used in conventional vehicles, they can serve as the power source to drive the vehicle forward or backward.Industrial Equipment

In industrial automation, brushless motors are widely used for precise control and efficient operation in applications like mechanical arms, conveyor systems, CNC machines, and fans. High-precision CNC machines often employ synchronous permanent magnet AC servo motors, replacing DC servo motors.Medical

In medical equipment, brushless motors are used in surgical tools, infusion pumps, ventilators, etc., to achieve precise motion control and quiet operation. Brushless servo motors can drive systems in surgical instruments like surgical robots, forceps, dissectors, etc.Learning from Our BLDC Motor Development Cases

Project Features:

- Output power exceeding 1.5KW

- Controller dimensions: 50708mm (excluding wires and electrolytic capacitors)

- USB Type-C interface

- Three-phase current sampling with quiet HFI function

- I/O with ESD protection

- USB power-off function; requires connection to power source to operate

Electrical Specifications:

- Maximum input voltage: 80V

- Phase current: Continuous 60A, Instantaneous current >75A

- Sampling current range: ±82.5A

- Recommended input voltage: <65V

Note: When using a switched power supply, it may be necessary to reduce the usage, and set Battery Current Max Regren to -0.1A.

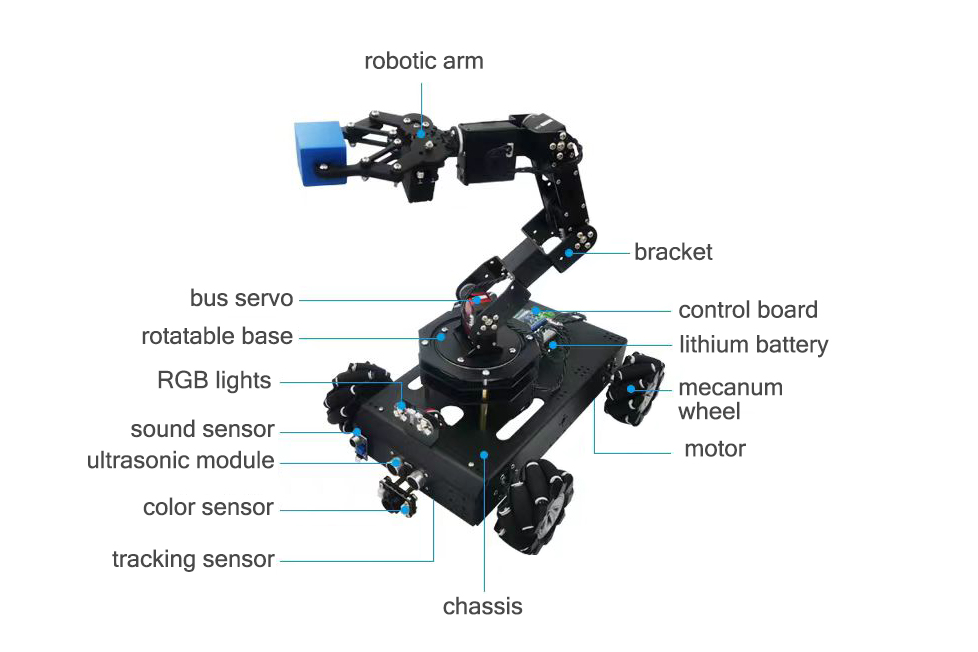

Project Features:

Control method: mobile app, PS2 controller, wearable gloves;

Color recognition, directional picking of objects, obstacle avoidance;

Applicable to various industrial environments with high reliability;

High power output, capable of driving large robotic arms and loads;

Advanced control algorithm to achieve precise position and speed control;

Electrical Specifications:

- Voltage range: 48V

- Maximum output power: 1.5KW

- Programmable control interface for easy integration with industrial automation systems.

Suitable for: robotic arms and motion control systems in industrial automation fields such as automobile manufacturing, logistics, and assembly lines.

Project Features:

- High Power Output: Capable of delivering over 10KW, ideal for precise power transmission in CNC machines.

- Precision Positioning: Utilizes closed-loop control systems and encoder feedback for accurate motion control.

- Efficient Thermal Management: Incorporates advanced cooling techniques for optimal heat dissipation.

- Flexible Control: Supports multiple drive modes and control algorithms to meet diverse machining needs.

Electrical Specifications:

- Motor Types: 80/90/110/130ST

- Motor Power: 1.5KW 2.3KW 5.5KW

- RPM speed: 3000

- Maximum Input Voltage: 220V

- Phase current: 30A continuously, instantaneous current exceeds 50A

- Sampling current range: ±40A

- Recommended input voltage: <200V

Project Features:

- Output power exceeding 2.5KW

- Compact controller design for easy integration into scooter frame

- Integration with smartphone app via Bluetooth for remote control and monitoring

- Waterproof and dustproof design for outdoor use

- Built-in overcurrent and overvoltage protection

- Compatible with both lead-acid and lithium batteries

Electrical Specifications:

- Maximum input voltage: 72V

- Phase current: Continuous 80A, Peak current >100A

- Efficient regenerative braking system

- Intelligent temperature monitoring for motor protection

Project Features:

- Designed for underwater exploration and inspection applications

- Corrosion-resistant materials for prolonged underwater use

- Compact and lightweight design for easy maneuverability

- Integrated thruster control system for precise navigation

- Low-noise operation for minimal disturbance to aquatic life

Electrical Specifications:

- Maximum input voltage: 48V

- Phase current: Continuous 40A, Peak current >60A

- Specially coated PCB for increased water resistance

- Integrated depth sensor for automatic depth control

How to Start Your BLDC Motor Project?

Submit Requirement

At first, please submit your specific requirement below, as long as your contact info.

Design & Development

After evaluating the BLDC Motor project, our engineers start to design and develop it.

Test & Debbug

Once the development job is done, the BLDC motors will be tested by professional devices.

Deliver

At last, we will arrange the shipment for you. If any problem when using the product, feel free to contact us.