PCB Forward Engineering Services

What is PCB Forward Engineering?

Forward engineering in PCB development refers to the proactive process of designing and implementing electronic circuits and systems from scratch, aiming to achieve specific functionality and performance goals. Unlike reverse engineering, which involves dissecting existing designs to understand and replicate them, forward engineering begins with a clean slate, allowing engineers to innovate and create novel solutions.

Benefits of Forward Engineering in PCB Development

The forward engineering in PCB development empowers engineers to create bespoke electronic solutions that meet the evolving demands of modern industries. By embracing innovation, efficiency, and collaboration, forward-engineered PCBs drive technological advancements and facilitate progress in diverse applications.

- Customization: Tailored solutions designed through forward engineering meet specific project requirements, offering customized features and functionalities.

- Innovation: Forward engineering fosters innovation by encouraging exploration of new design approaches, technologies, and techniques.

- Efficiency: Starting from scratch allows for efficient optimization, resulting in streamlined designs with improved performance and cost-effectiveness.

- Scalability: Forward-engineered PCBs are adaptable to future needs, supporting scalability and accommodating technological advancements.

- Quality Assurance: Through rigorous design validation and testing processes, forward engineering ensures high-quality, reliable PCB solutions.

Our PCB Forward Engineering Services

Our forward engineering team excels in offering tailored functional development services for your PCB needs. We specialize in a diverse range of products, including, but not limited to:

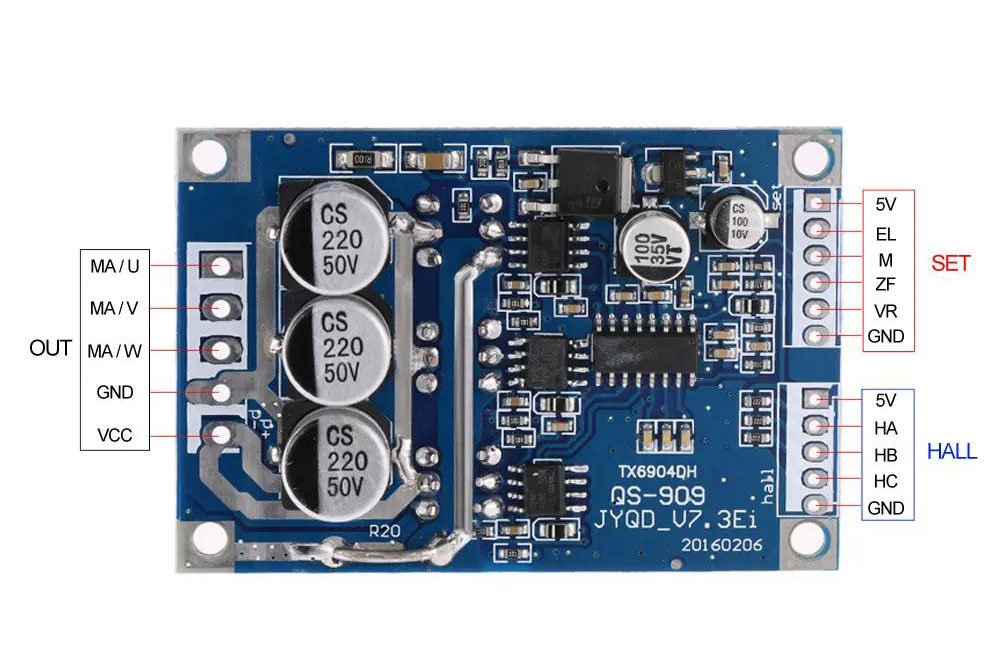

- Sensory or non-sensory brushless motors

- Square wave or FOC (Field Oriented Control) drivers

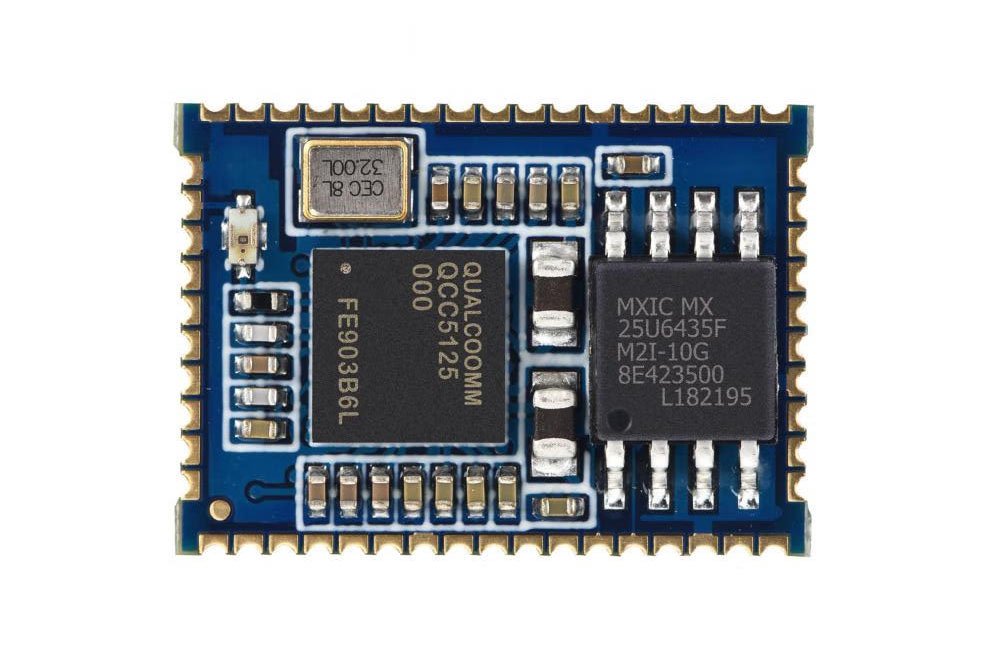

- Bluetooth modules

- Products adhering to the Modbus protocol

- Modules for air conditioning and refrigeration

- Temperature heating control solutions

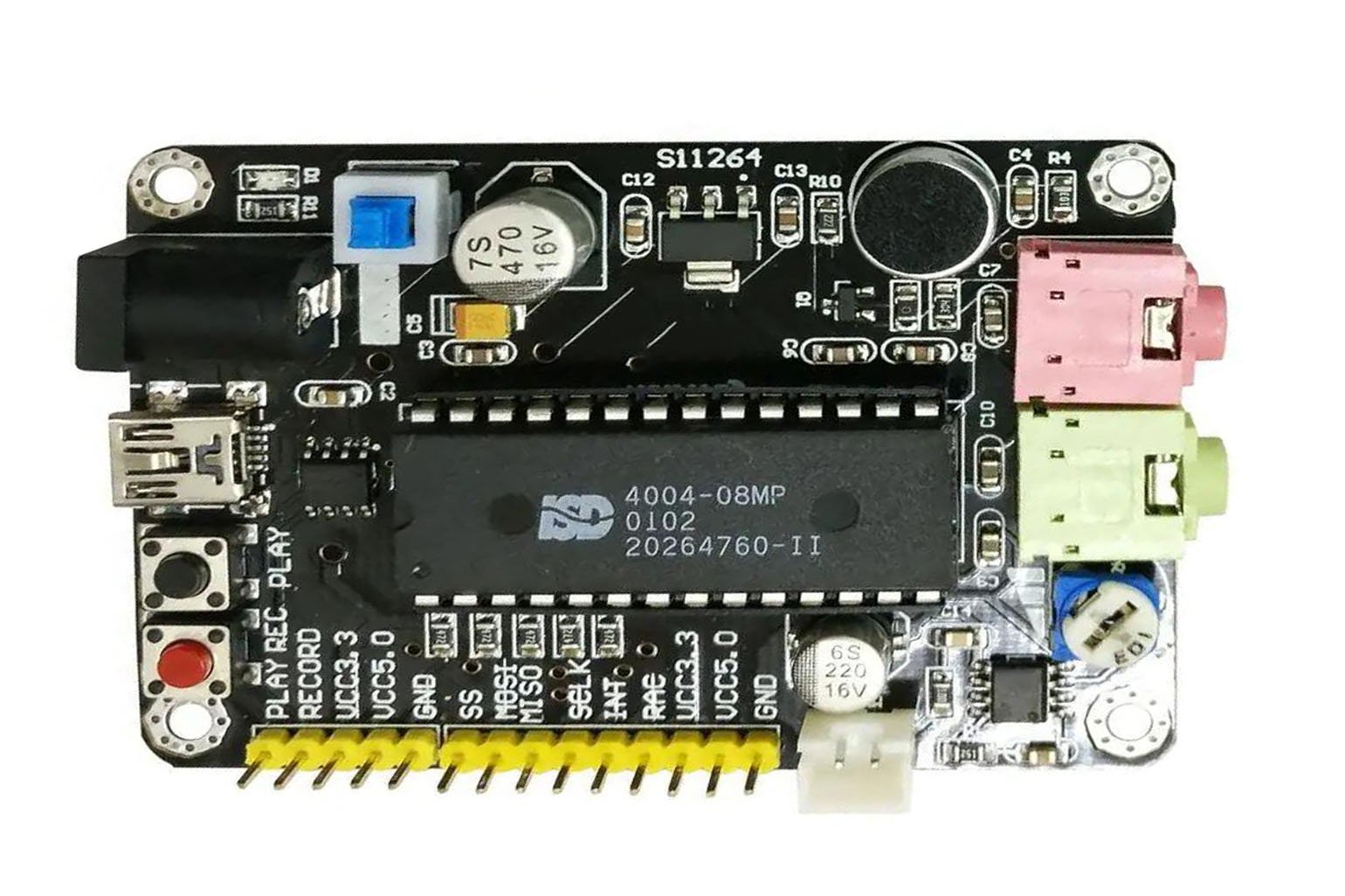

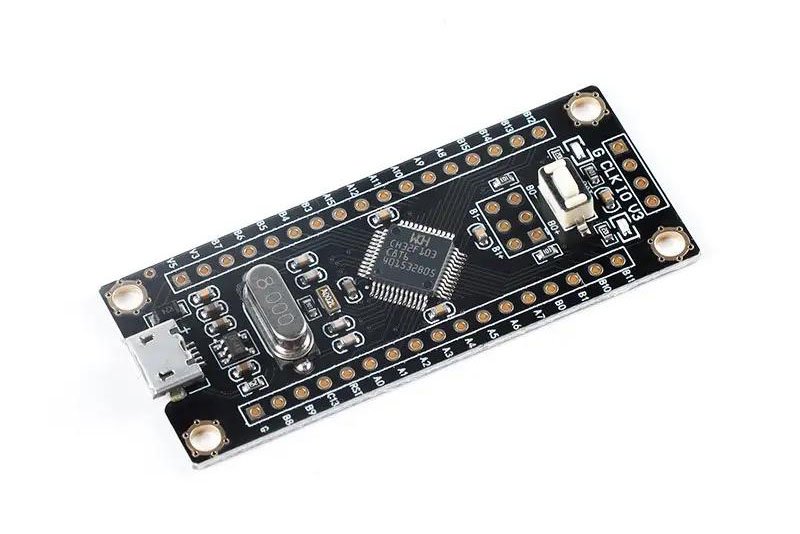

- Microcontrollers ranging from 8-bit to 32-bit architectures

With our expertise and commitment to excellence, we ensure that your PCB requirements are met with precision and efficiency.

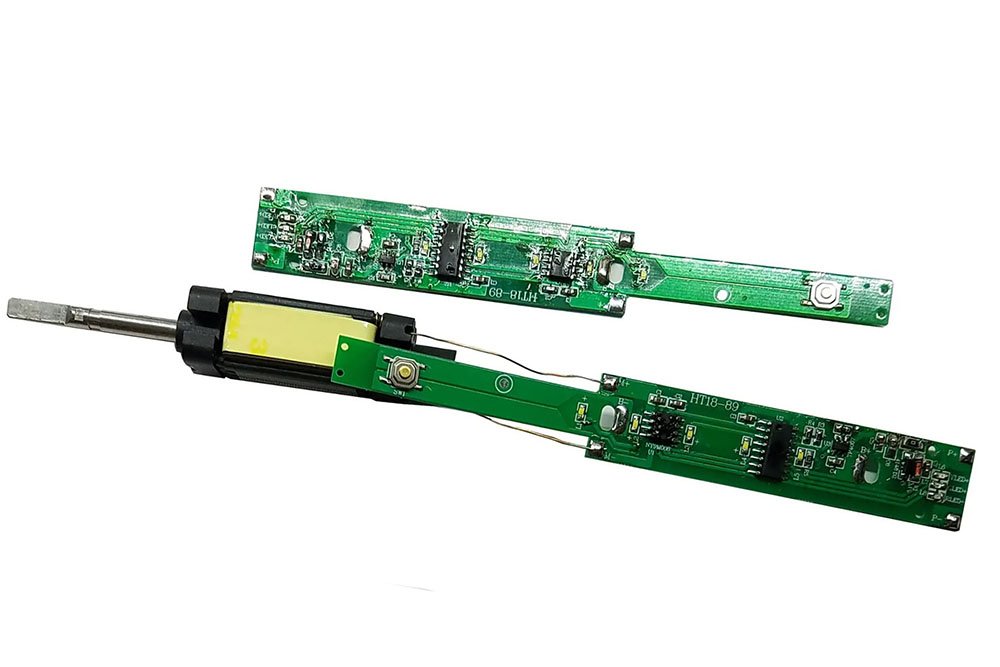

Case Studies of PCB Forward Engineering

Below are our cases of forward engineering in PCB development. The tables outline the key details of each PCB forward engineering project, including functionality requirements, specifications, and development results.

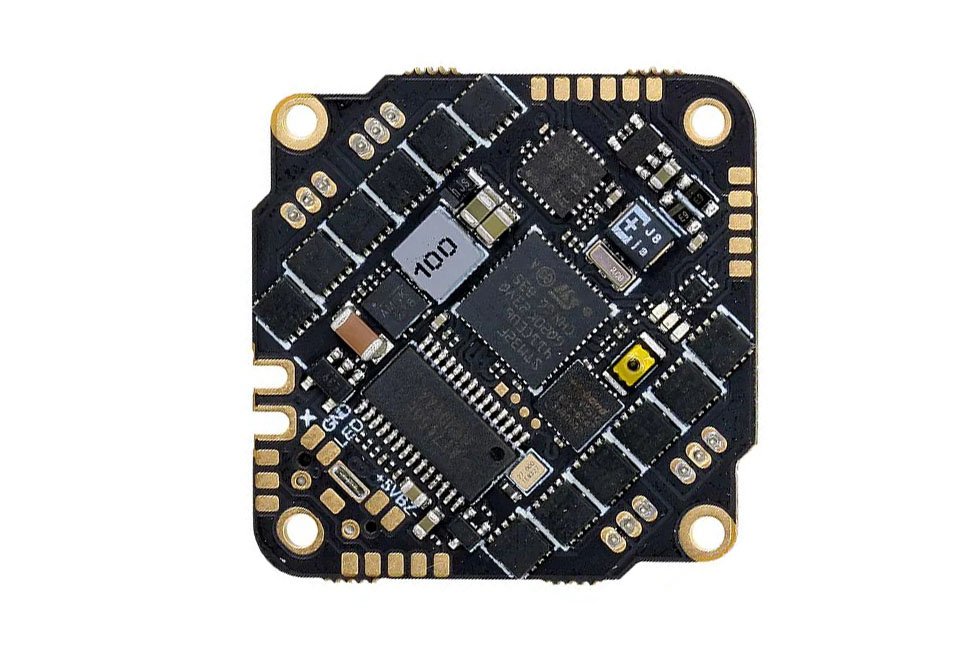

| Project Name | Drone Flight Controller System |

|---|---|

| Functions | Drone flight control and data acquisition |

| Specifications |

|

| Result | Successfully developed a high-performance PCB design for the drone flight controller system. |

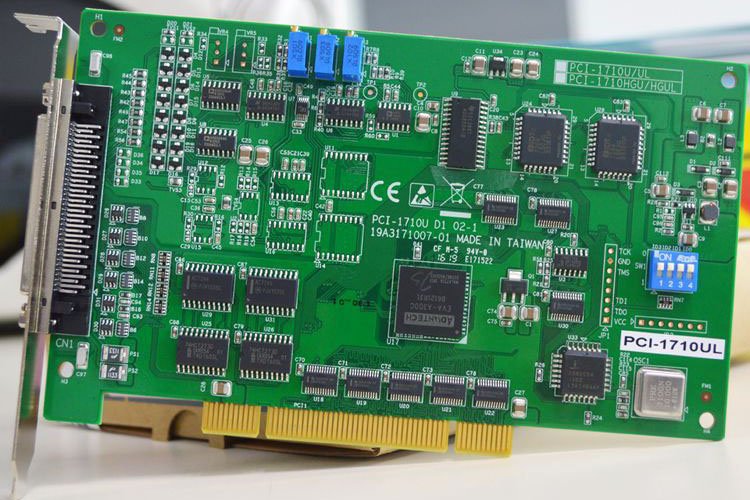

| Project Name | High-Speed Data Acquisition System |

|---|---|

| Functions | PCB capable of high-speed data transmission and signal acquisition |

| Specifications |

|

| Result | Delivered a high-performance PCB design capable of reliable data acquisition and transmission at high speeds, meeting project specifications and performance requirements. |

| Project Name | IoT Sensor Node for Environmental Monitoring |

|---|---|

| Functions | PCB for collecting and transmitting environmental data in IoT applications |

| Specifications |

|

| Result | Successfully developed an IoT sensor node PCB with optimized power consumption, wireless connectivity, and sensor integration, enabling real-time environmental monitoring in IoT systems. |

| Project Name | Electric Toothbrush PCB Device |

|---|---|

| Functions | Electric toothbrush control and data processing |

| Specifications |

|

| Result | Successfully developed a compact and high-performance PCB design for the electric toothbrush device, ensuring efficient brushing functionality and reliable data processing. |

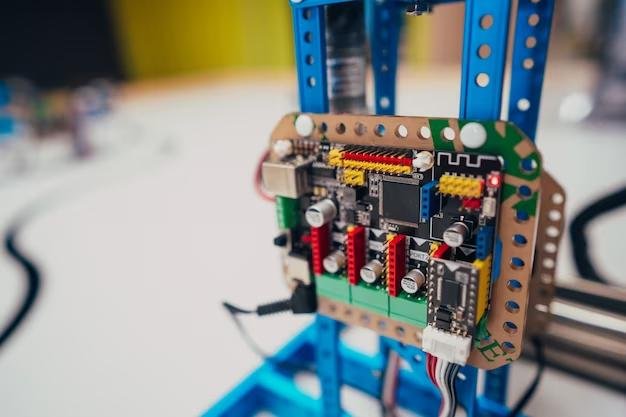

| Project Name | Balance Car Control System |

|---|---|

| Functions | Controlling a balance car and data acquisition |

| Specifications |

|

| Result | Successfully developed a high-performance PCB design for the balance car control system, ensuring precise motor control and stable balance operation. |

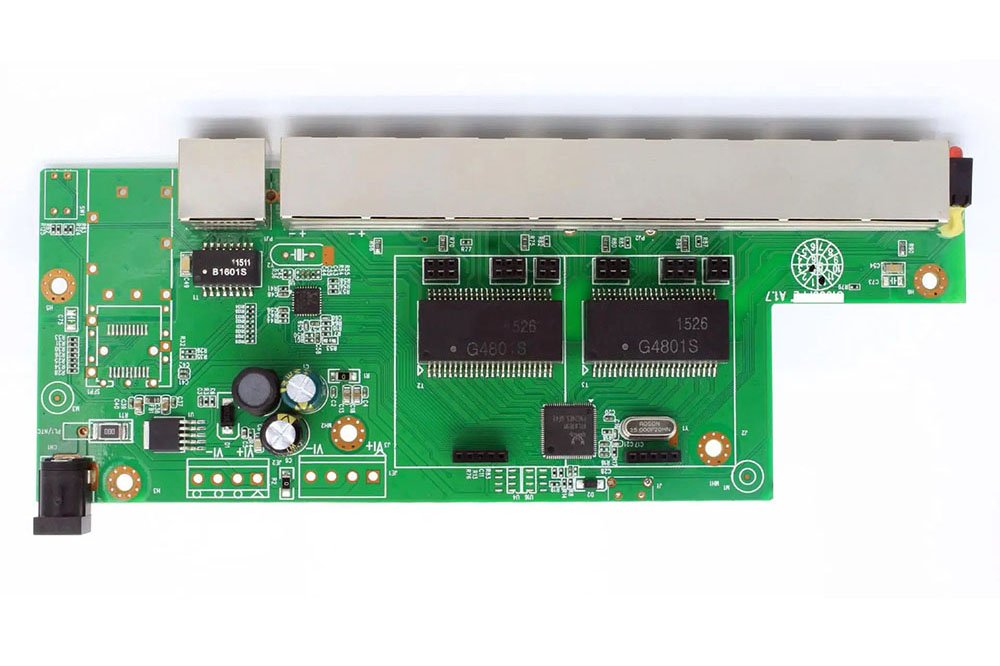

| Project Name | Smart Home Control Hub |

|---|---|

| Functions | PCB for centralizing control of smart home devices |

| Specifications |

|

| Result | Developed a versatile smart home control hub PCB enabling seamless integration and control of various smart home devices, enhancing convenience and automation in home environments. |

FAQ

What are the primary steps involved in PCB forward engineering development?

The primary steps in PCB forward engineering development typically include requirements gathering, schematic design, PCB layout, prototyping, testing, and manufacturing.

What tools are commonly used in PCB forward engineering development?

Common tools include CAD software for schematic capture and PCB layout (e.g., Altium Designer, Eagle), simulation tools (e.g., SPICE, PSpice), and prototyping equipment (e.g., PCB fabrication machines, 3D printers).

How to choose components for a PCB forward engineering project?

When selecting components, factors such as performance, reliability, availability, cost, and compatibility with the design requirements must be considered. Additionally, factors like lifecycle, sourcing, and potential obsolescence should be evaluated for long-term viability.

How do you manage thermal issues in PCB forward engineering designs?

Thermal management in PCB forward engineering designs involves careful consideration of component placement, heat sinking, thermal vias, and proper ventilation. Thermal simulations and testing help identify and address potential hotspots.

How do you ensure compliance with regulatory standards and certifications?

Compliance with regulatory standards and certifications involves thorough understanding and adherence to applicable standards (e.g., IPC standards, CE, UL, FCC). Testing, documentation, and collaboration with certification bodies are essential for achieving compliance.

Why Choose Our PCB Forward Engineering?

15 years R & D Experience

We have been specializing in PCB forward engineering services for over 15 years, serving more than 3,000 customers worldwide.

One-stop PCBA Solution

We possess the latest professional production equipment to handle the PCB forward engineering projects and provide complete service from design analysis, program design, sample, and mass production as a one-stop solution.

Professional Technical Team

Equipped with a professional PCB development team, industry-leading production equipment and professional technical management team.

Our Clients

Our customers are primarily located in the North American, European and Asian continents. As a PCB assembly company, we have been doing business with our clients for more than 15 years. Our high-quality PCBs can be manufactured according to customer’s design or specifications of their own choice, as per industry standards and quality norms approved by IPC A 004 – 93: 2006.

Resources

Electronic Manufacturing Services: A Comprehensive Guide

Explore the ins and outs of electronic manufacturing services, including contract manufacturing and supply chain management, to streamline production and cut costs efficiently.

Understanding IPC 6011: Key Concepts Explained

Explore the essential guide to IPC 6011, the key standard for PCB quality in electronics. Learn its impact on design, manufacturing, and compliance.

Effective Circuit Board Testing: Step-by-Step Guide

Learn how to test a circuit board efficiently with our comprehensive guide. Discover tools, safety tips, and methods for accurate electronic testing.