In the world of manufacturing and software, it’s not uncommon to hear words like reverse engineering or forward engineering. But what do those terms mean, and how do they apply to you? Let’s take a look at what these terms mean and how they can be used in your business.

These are two techniques that are often used by engineers when designing new products. Forward engineering involves building something from blueprints, CAD files, or other pre-existing plans. In contrast, reverse engineering is taking something that has been made and figuring out how it was constructed.

Reverse Engineering

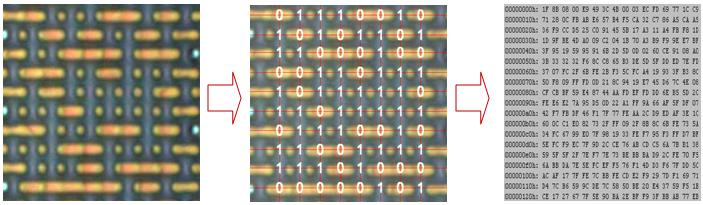

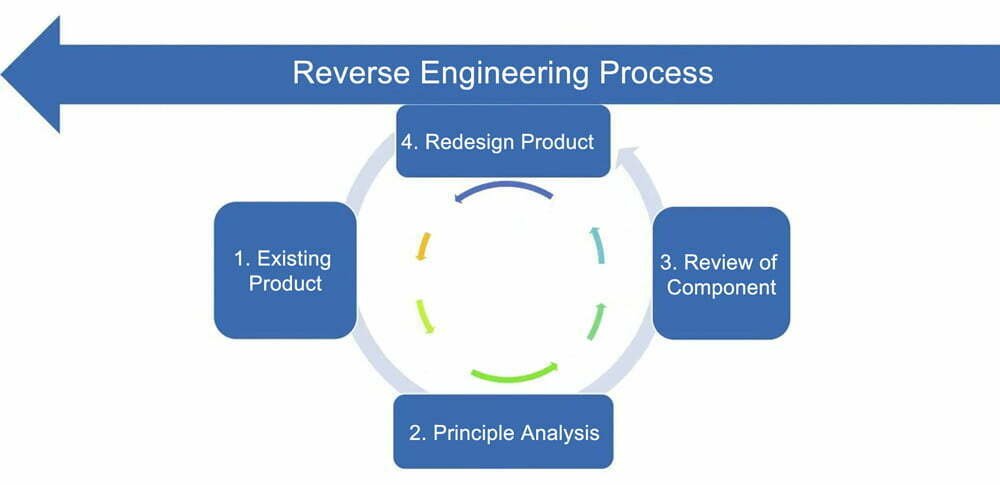

Reverse engineering (also termed reverse technology) is a design technology that allows a product to be recreated. It is a procedure in which a product is reverse-analyzed and researched to discover the processing flow, organizational structure, functional characteristics, and technology specifications of the product, resulting in a product that performs similarly but looks different. Reverse engineering originates in the military and commercial sectors. The purpose of reverse engineering is to establish the design principles of a product without obtaining the vital production information in situations where it is inaccessible.

Reverse Engineering Applications

Reverse engineering is required for the following reasons:

Product Analysis: investigate how the product works, the composition of its components, estimate the budget, and identify potential infringements.

Recover Loss Files: the files of a special device have been lost, and the person in charge of the project cannot be found at the same time. With the RE engineering, you can get PCB diagram schematic, BOM list and ICs bin or C files.

Software / Hardware Upgrade: analyze the existing product, replace the main board, redesign the old system, and integrate the original function to the new project.

Access Login Permission: Remove or disable the device security section for device activation.

Military or Commercial Secrets: steal the latest research or product prototypes from an enemy or competitor.

Academic/ Learning Purpose: bioengineering, teaching and research.

Forward Engineering

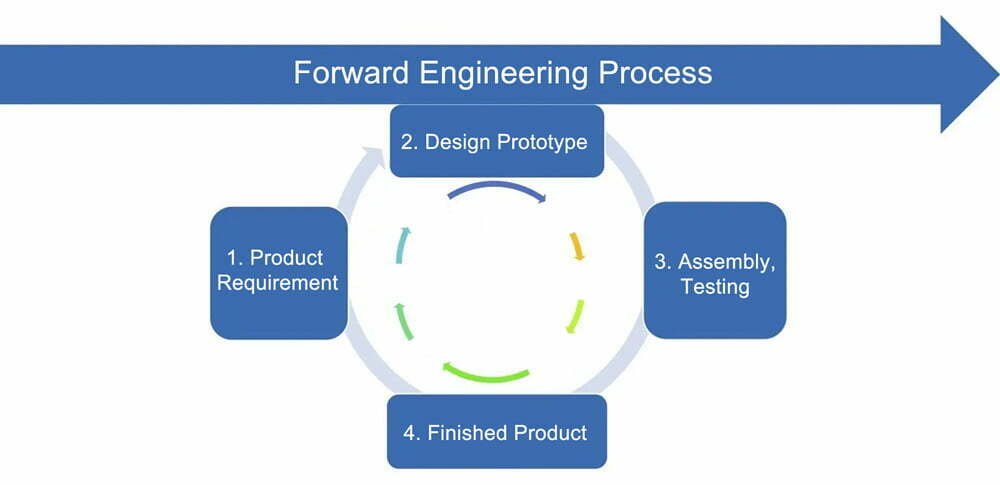

The forward engineering is a procedure of creating products beginning with design and ending with a product.

Engineers initially conceives the product’s exterior appearance, structure, general technical parameters, starting from the expected function and specification target. Next, they design, manufacture and inspect each component, and complete a wide range of data models. This process is then transferred to the development process, including assembly and performance testing. At the end, all result in a finished product design and development cycle. A product design process like this is known as ‘forward engineering’.

Contrast between forward engineering and reverse engineering

1. Forward engineering requires application development with the required specifications. While reverse engineering obtains information from the applications.

2. Forward engineering is a more time-consuming and complex process than reverse engineering.

3. In forward engineering, production begins with the required specifications. In reverse engineering, production begins with existing products.

Challenges of Forward Engineering

The main challenge of forward engineering is that it can be difficult to accurately predict the future. This is because it can be hard to know what technology will be available in the future, and how it will be used. Additionally, it can be difficult to anticipate changes in user needs and preferences. As a result, forward engineering can sometimes result in products that are outdated or no longer meet the needs of users.

Challenges of Reverse Engineering

There are several challenges associated with reverse engineering, particularly when it comes to software. One challenge is understanding the code itself; software is often complex and may be written in a variety of programming languages, making it difficult to decipher. Another challenge is figuring out how the code works in the first place; this can be difficult, especially if the code is obfuscated or minified. Additionally, reverse engineering often requires access to the source code, which may not be available, or may be protected by copyright or other intellectual property laws. Finally, even if reverse engineering is successful, it may be difficult to create a working copy of the software that is identical to the original.

Related Post