Keeping track of the components used in your electronics projects is important for several reasons. A bill of materials (BOM) lists all of the components used in a product along with their quantity, details, and origin. In this article, we’ll walk you through how to generate a bill of materials in PCB design and reverse engineering.

What is a PCB BOM?

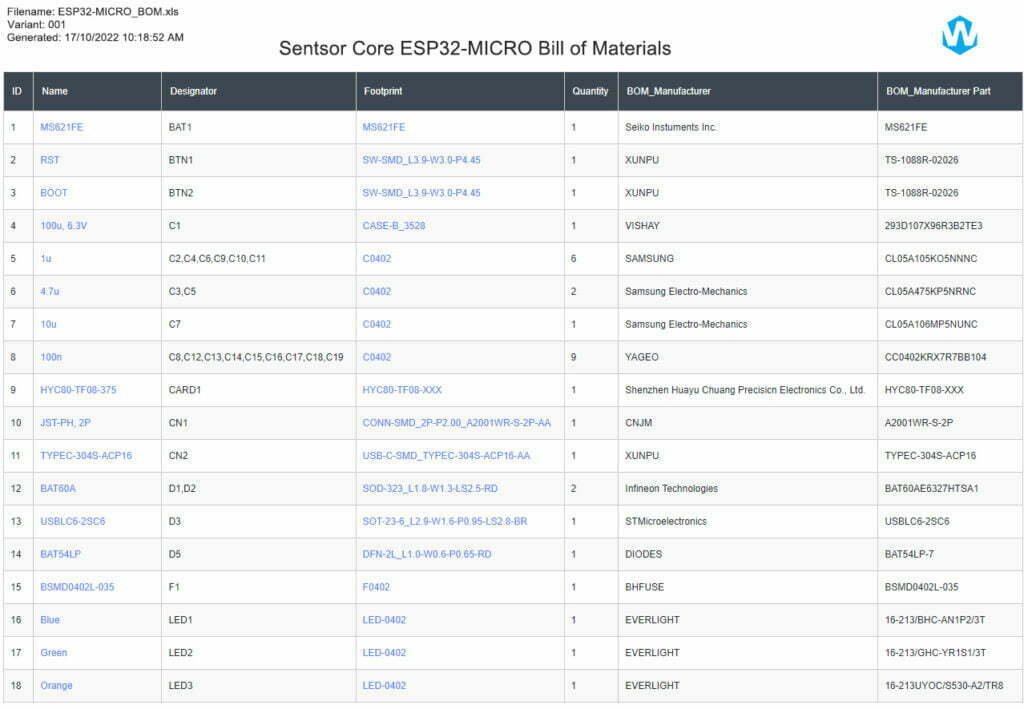

A BOM (bill of materials) is a list of components and quantities used in PCB designs. It can also include a reference to the manufacturer, supplier, or part number details. Ideally, you should try to create a BOM for each PCB design so you can track down any issues, rework, or sourcing problems at a later date.

Where is BOM used for?

A BOM is used in various tasks including risk analysis, identifying cost savings, checking purchasing specifications, and quality control. It can be used to estimate the profit margin and net present value of a product or business venture. So it’s an important document to have in your back pocket. BOMs are commonly used in the manufacturing industry to track inventory and keep track of materials used in the creation of a product. In PCB design, a BOM is used to list all of the components attached to a PCB layout and the quantity used.

Why Create a PCB Bill of Materials?

The primary reason to create a BOM in PCB design is to keep track of the electronic component. It’s important to note the quantity of each component and the quantity of the PCB layout since the two are often confused. You’ll also use a BOM to track down sourcing details for each component used in your boards. This can be helpful if a particular part fails or a supplier goes out of business so you can find an alternative source. Finally, you’ll also use a BOM as a guide to estimate the cost of creating a PCB board. This can help you create a budget and understand the financial implications of creating a PCB board. Meanwhile, a BOM can also help you cost effective by finding cheaper suppliers and cheaper alternatives to your components.

How to Create a PCB Bill of Materials?

There are 4 ways to create a BOM in your PCB design files: download templates online, use bom generator, manually making or using PCB design software. Creating a BOM manually is straightforward but can be time-consuming. You can use any type of text editor to list the components by title, part number, or manufacturer. You can then save your bom formats in a .csv file or .txt file so you can insert it into your PCB design spreadsheet.

1. bom templates

2. Manually Creating

include in your bom:

Reference Designator: The position of these components can be quickly located on the schematic diagram, and the components can be installed in the correct position when the PCB is soldered and installed (marked by silk screen);

Quantity: The number of devices of the same model on a board;

Part number: The model of each device is different, just like each of our ID cards, the difference is that the same model may correspond to different manufacturers, and the manufacturer’s information needs to be marked in the BOM;

Value: For example, the value of devices such as resistors and capacitors;

Manufacture/vendor: The original factory that provides the device;

Description – Relatively complete information given on the characteristics of the device, according to which the requirements of the device can be correctly parsed.

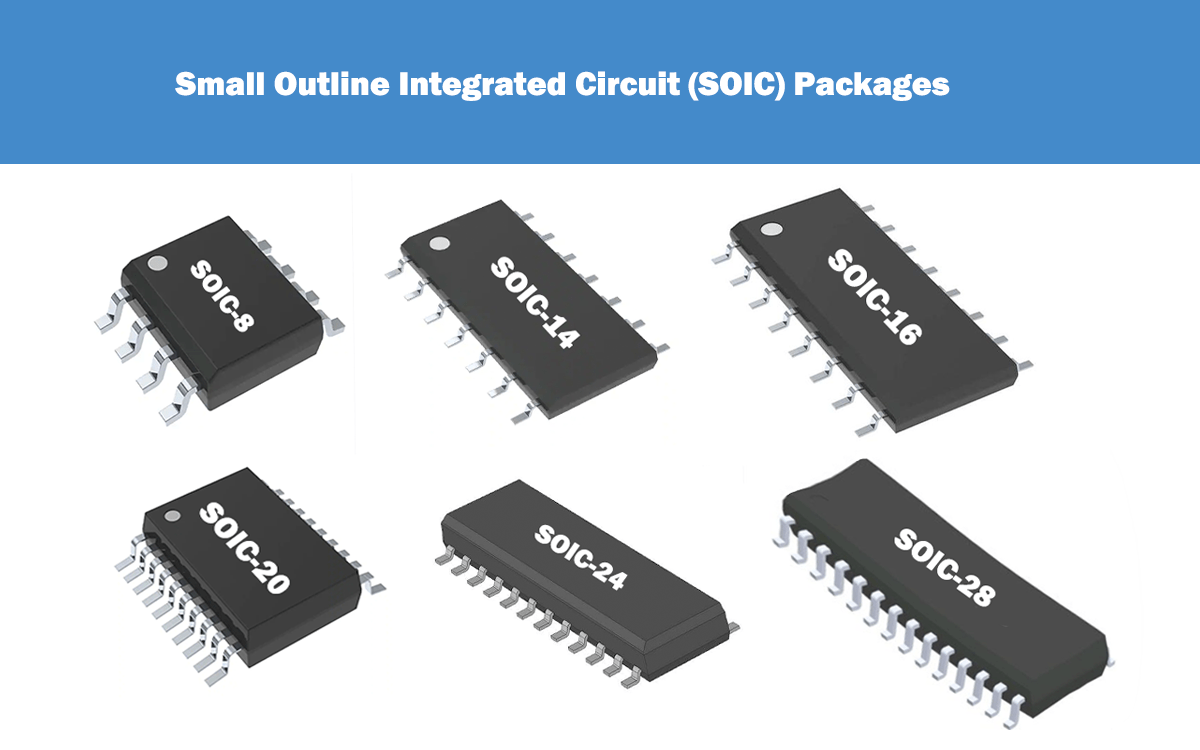

Footprint/Package: The installation information on the circuit board corresponding to the device.

3. BOM Generator

Alternatively, you can also use a BOM generator to help you automate the process. These are helpful if you have a large number of components in your BOM as you can save a lot of time by uploading your files and generating a BOM. PCB design software will often have BOM options built in so you can create a BOM directly in your design file. This is particularly helpful if you’re creating a BOM for the first time as you can quickly generate a BOM and place it in your PCB design files.

4. Exporting BOM from Design Software

There are a few different ways that you can export a bill of materials (BOM) from your design software. One way is to use a plugin or extension that is specific to your software. For example, if you are using Autodesk Inventor, you can use the BOMExporter plugin. Another way is to use a generic CAD converter tool. These tools can often export BOMs from a variety of different software programs. Finally, you can always export your BOM as a CSV file. This can be done in most design software programs by going to the File menu and selecting Export > Bill of Materials.

Tips When Creating a PCB BOM

Keep in mind a few tips when creating a BOM in your PCB design files.

First, make sure you include the quantity of each component used on your PCB layouts.

Second, if your design is complex, consider grouping similar components together in your BOM. This will make it easier to keep track of the components used.

Third, if you’re creating a BOM for the first time, keep it simple and don’t overcomplicate it. You’re not creating a guide for electronic engineers; you’re creating a quick reference guide for yourself.

Finally, a BOM is an important and necessary document for any PCB designer. If you’re not creating one yet, don’t worry as we’ve got you covered with these tips and tricks!