Printed circuit boards (PCBs) are the backbone of modern electronics. They are used in a wide range of applications and are essential for the functioning of all electronic devices. PCBs contain a variety of components and connectors, and PCB connectors are essential for the proper functioning of the PCB and the device. In this article, we will discuss the connectors and their importance in electronics.

What are PCB Connectors?

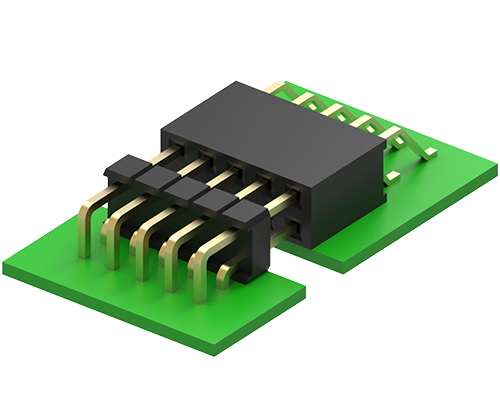

PCB connectors are devices used to connect two or more electrical components on a printed circuit board. They are usually made of plastic and have metal contacts on the bottom that connects to the PCB. In addition, they are available in a variety of shapes, sizes, and configurations to accommodate different types of components.

PCB Connector Types

There are many types of connectors available for pcb connection in the market. The most common types are:

Wire-to-Board Connector

A wire-to-board connector is a type of electrical connector designed to join a wire or cable to a printed circuit board (PCB). It is typically used for connecting a power supply, components, or other devices to a PCB. The connector typically consists of a male or female plug, or a socket, with a series of pins or sockets.

Types:

FFC connector, FPC connector, LVDS connector, power connector, header, socket connectors and more.

Board-to-Board Connector

Board-to-board connectors connect two PCBs close together by pcb connector pins. They can be soldered directly onto the PCBs, or supplied with a socket for the PCB to plug into. They are usually used for pcb stack or providing mechanical support.

Types:

Pin headers, female headers, box headers, etc.

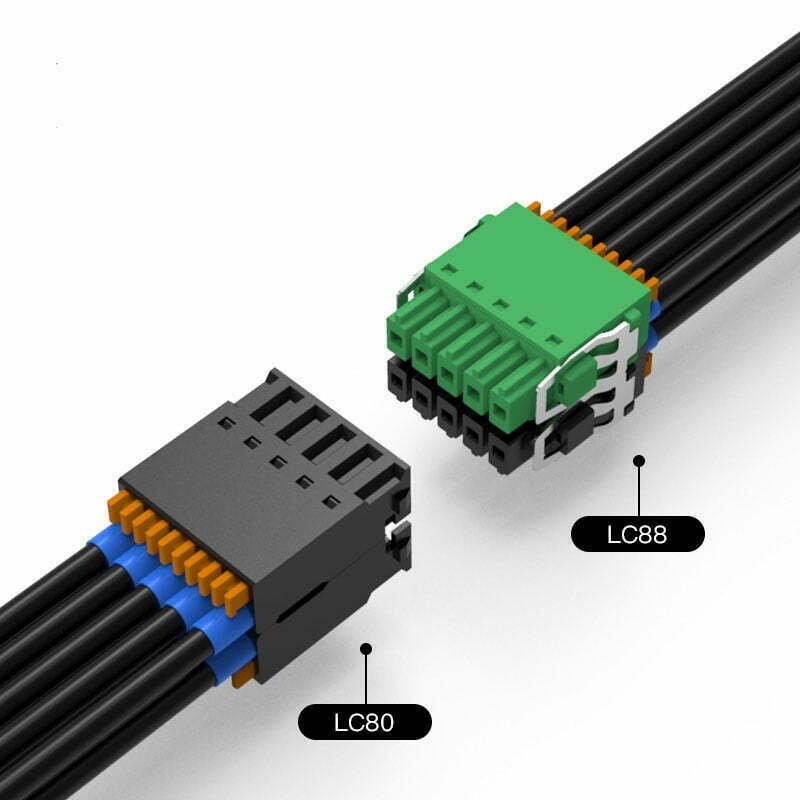

Wire-to-Wire Connector

The wire-to-wire connectors connect two cables or wires together in a single connection. They are available in a variety of shapes and sizes. They are used in a wide range of applications, from automotive and industrial applications to the computer.

Types:

electrical connector, computer connector, crimp to crimp, IDC to IDC connector, FFC to FPC connector, crimp to IDC connector, etc.

Benefits of Using Connectors

PCB connectors offer many benefits to the electronics industry. They provide a secure connection between components and PCBs, and are designed to be reliable and versatile.

- Cost savings: They are available in a variety of sizes and configurations, so they can be used in a variety of applications. This saves time and money, as the same connector can be used in multiple applications.

- Reliability: They are designed to be reliable and durable. They are designed to withstand temperature changes and vibration, which helps to ensure a secure connection between components and PCBs.

- Versatility: They are designed to be versatile, so they can be used in a variety of applications. This allows for greater flexibility in design.

How to Choose the Right PCB Connector?

When choosing a PCB connector, it is important to consider the application and the type of components that need to be connected. Different types of connectors are better suited to different applications. Here are some tips to help you choose the right PCB connector:

- Consider the application: Different types of connectors are better suited to different applications. Consider the application that the connector will be used in, and choose the connector that best suits the application.

- Consider the size: Different types of connectors are available in different sizes. Consider the size of the components that need to be connected, and choose the connector that best fits the size of the components.

- Consider the configuration: Different types of connectors are available in different configurations. Consider the configuration that best suits the application, and choose the connector that best fits the configuration.

PCB Connector Design Considerations

When designing a PCB connector, it is important to consider several factors:

- Number of pins: The number of pins to use depends on the number of connected signals.

- PCB connector pitch: Most of cable-to-board or board-to-board connectors on 1mm-5mm pitch.

- Electrical properties: The electrical properties of the connector mainly include: limiting current, contact resistance, insulation resistance and dielectric strength.

Common Applications

Printed circuit board connectors are used in a variety of applications, including:

- Automotive: such as engine control systems, fuel systems, and much more.

- Computers: such as motherboards, hard drives, and much more.

- Telecommunications: such as cellular phones, routers, and much more.

- Industrial: such as factory automation, robotics, and much more.

Different Types of Connector Contacts

PCB connectors are available with a variety of different types of contacts. The type of contact used depends on the application and the type of components that need to be connected. The most common types of contacts are:

- Pin contacts: These are used to connect components to a PCB.

- Socket contacts: These are used to connect components to a PCB.

- Edge contacts: These are used to connect two PCBs together.

Conclusion

PCB connectors are essential components in electronics. They provide a secure connection between components and PCBs, and are designed to be versatile and reliable. There are many types of connectors available in the market, and it is important to choose the connector that best suits the application.