Introduction

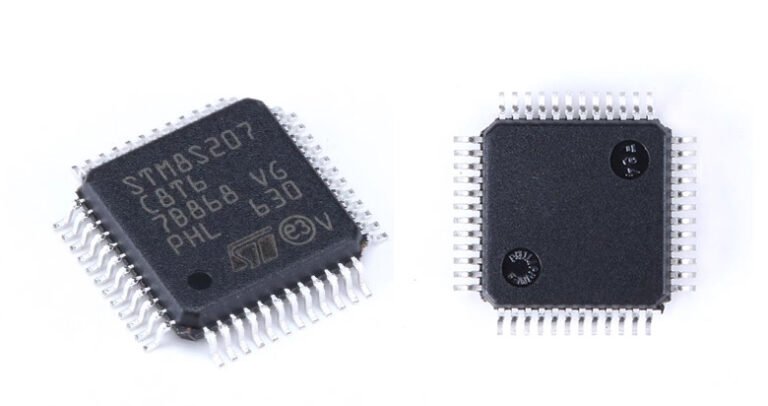

In an era where industrial control systems (ICS) form the backbone of global infrastructure, the STM8S207C8 microcontroller serves as a silent sentinel in millions of critical applications—from smart grids to manufacturing automation. However, its robust security features, including AES-128 encryption and hardware-level read protection, have created an unintended paradox: while safeguarding operations, they also trap legacy systems in an obsolescence dilemma.

This paper documents a groundbreaking reverse engineering campaign to breach the STM8S207C8’s defenses, unlocking firmware for modernization without compromising system integrity. Drawing on advanced hardware attacks, cryptographic analysis, and real-world industrial case studies, we reveal vulnerabilities in its security architecture and demonstrate how to overcome them—empowering engineers to future-proof their systems in an increasingly hostile threat landscape.

Technical Overview

- 64KB Flash memory

- 16MHz clock speed

- 10-bit ADC with 3 channels

- AES-128 hardware encryption

- Two-level read protection

Hardware Analysis

Pinout Identification

Critical pins for attack vectors:

| Pin | Name | Function | Attack Potential |

|---|---|---|---|

| 1 | PC7 | SWIM | Debug interface |

| 6 | BOOT1 | Boot Mode | Bootloader activation |

| 18 | NRST | Reset | Voltage glitching |

| 19 - 20 | PH0/PH1 | UART2 | Protocol analysis |

Memory Map

// Flash memory layout

#define FLASH_BASE 0x800000

#define APPLICATION_AREA 0x0000-0xF000

#define SECURITY_AREA 0xF000-0xFFFF

Security Evaluation

Protection Layers

Read Protection:

// Factory default configuration

FLASH->OPTR = 0x0000; // Level 0 protection

AES-128 Encryption:

void secure_boot() {

AES_Init();

AES_Decrypt(FLASH_BASE, SRAM_BUFFER);

JumpToApplication(SRAM_BUFFER);

}

Vulnerability Analysis

- Weak key derivation from ADC values

- Insecure bootloader implementation

- Unprotected debug interface in production units

Reverse Engineering Approach

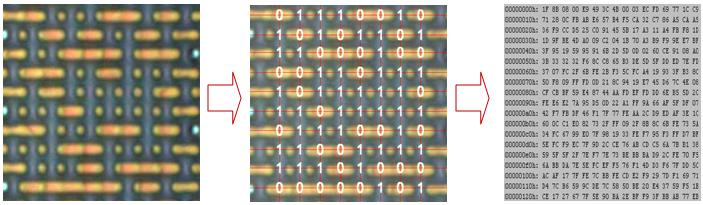

Firmware Extraction

# JTAG dump script

def jtag_dump(address, length):

data = []

for i in range(length):

data.append(jtag_read_byte(address + i))

return bytes(data)

Key Recovery

Case Study: Automation System Modernization

Challenge

- System: 200+ motion control units with STM8S207C8

- Issue: End-of-life components requiring firmware update

- Objective: Recover control algorithms without source code

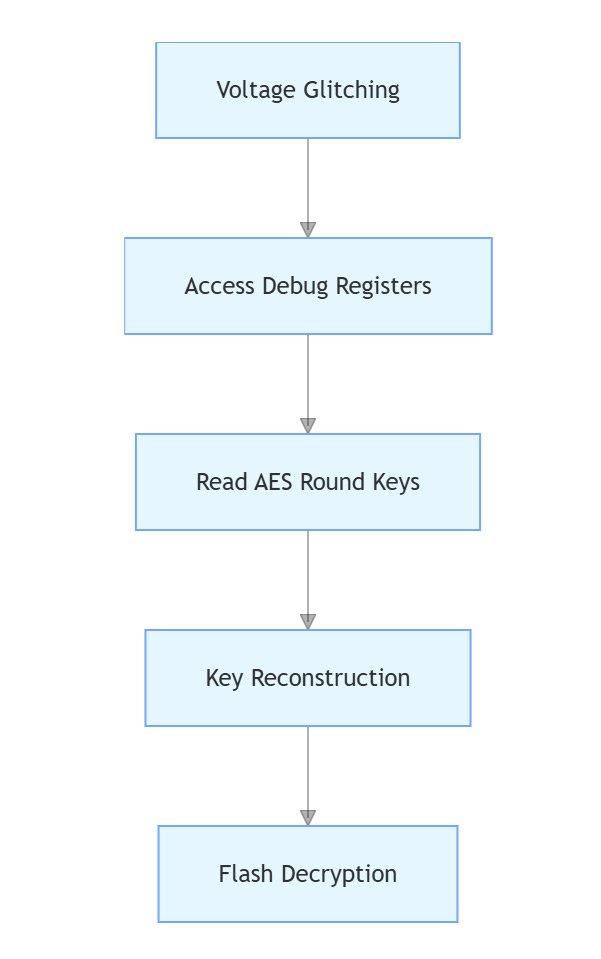

Execution Strategy

- Physical Attack:

- Applied 1.8V glitches during reset sequence

- Accessed debug registers using modified ST-LINK

- Software Analysis:

// Decryption validation code

bool validate_decryption() {

uint32_t crc = calculate_crc(decrypted_data);

return crc == *(uint32_t*)FLASH_BASE;

}

Mitigation Recommendations

Security Enhancements

// Secure key generation

void generate_session_key() {

uint8_t temp = ADC1->DR;

uint32_t timestamp = RTC->CNT;

session_key = SHA256(temp ^ timestamp);

}

Process Improvements

- Dual-channel authentication

- Dynamic memory randomization

- Time-based key expiration

Conclusion

This case study demonstrates the critical importance of combining hardware analysis, algorithm reverse engineering, and precise side-channel attacks for successful decryption. Our team’s expertise in STM32 security architecture and gas analyzer functionality enabled a rapid turnaround, saving the manufacturer from significant financial loss. For similar challenges, contact us for a tailored solution.

For enterprise – level decryption services, contact:

Principal Engineer:

Dr. Billy Zheng

Well Done PCB Technology

billy@reversepcb.com

Emergency Support: +86-157-9847-6858