What are PCB Vias?

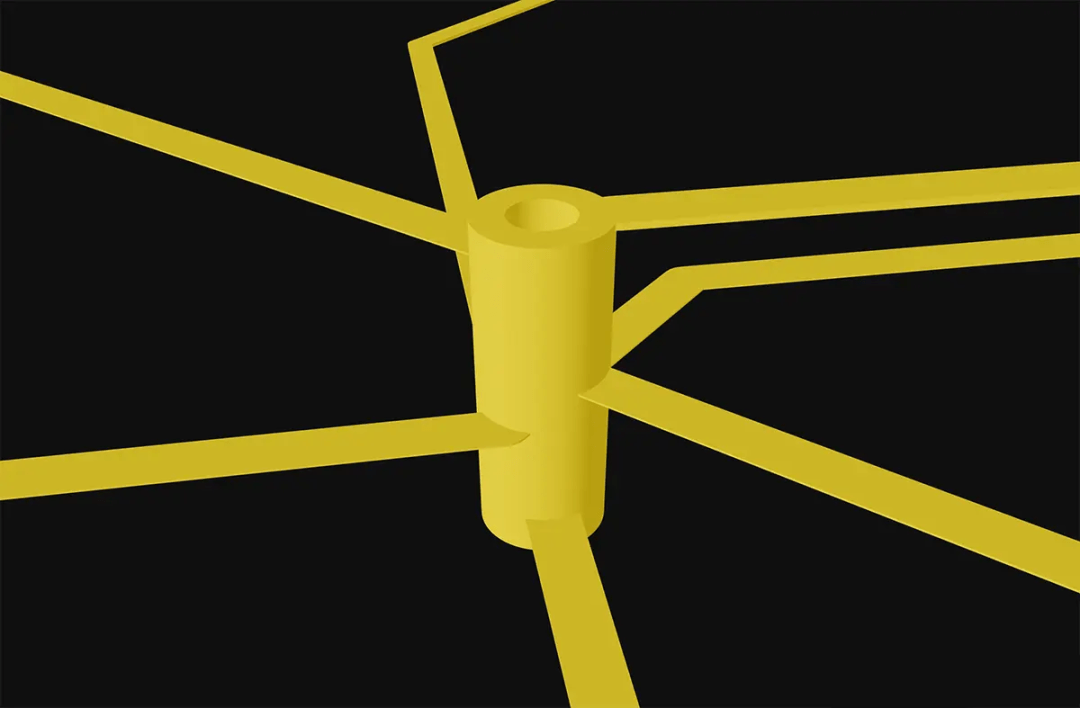

PCB vias are small conductive holes that provide electrical connections between different layers of a printed circuit board. They play a crucial role in enabling the flow of signals and power throughout the board.

Components of PCB Vias

- Barrel: A conductive tube used to fill the drilled hole.

- Pad: Connects the ends of the barrel to the traces.

- Antipad: A gap used to separate non-connected layers and the barrel.

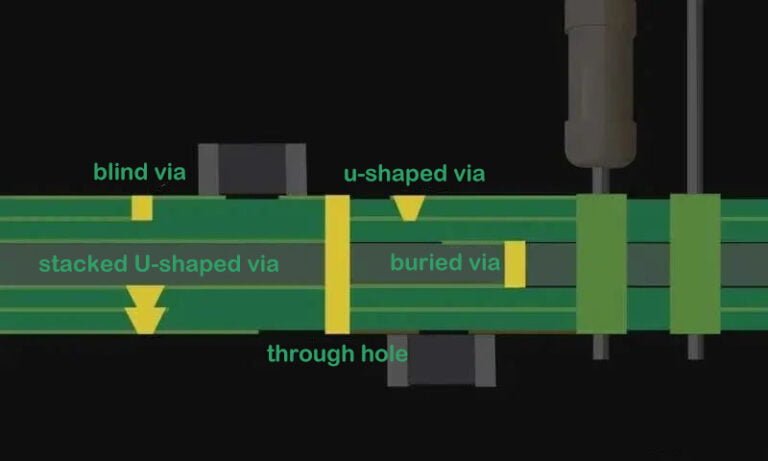

Types of PCB Vias

Let’s look at five main types of PCB vias:

Through-Hole

Through-holes are the most common type. They are created by drilling a hole in the PCB and filling it with conductive material like copper. Through-holes are often used to connect components to other layers of the PCB and provide structural support.

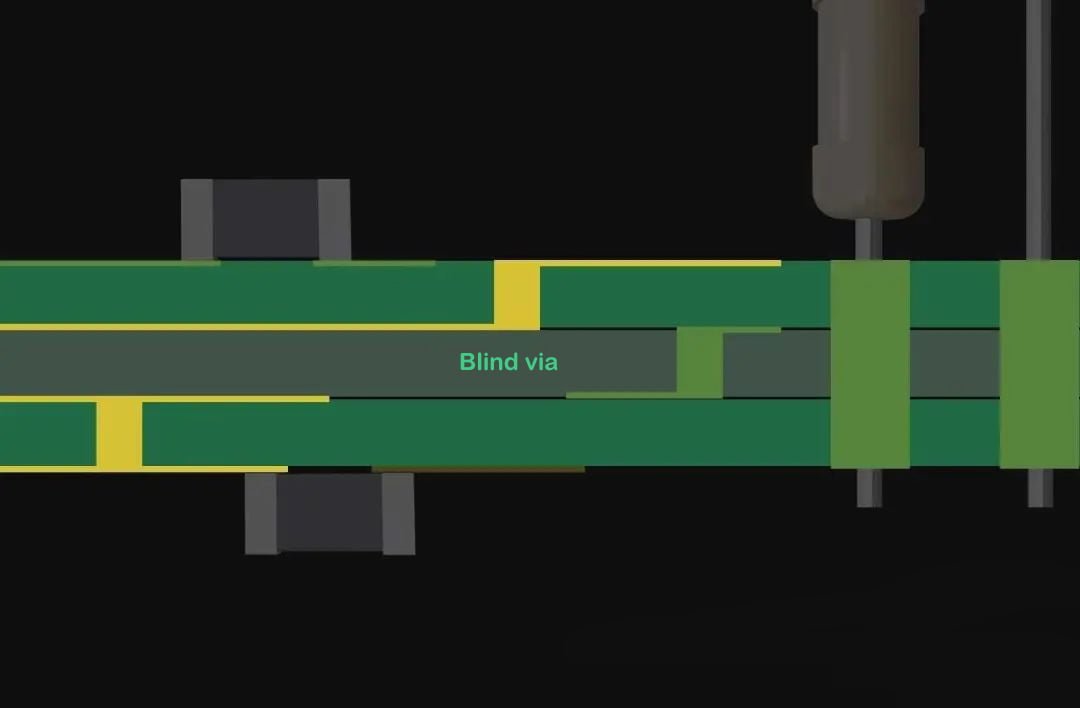

Blind Via

Blind via is similar to through-holes, but they only partially penetrate the PCB, connecting the outer copper layers to the inner ones without going through the entire board. Blind vias are useful for space-constrained multi-layer PCBs.

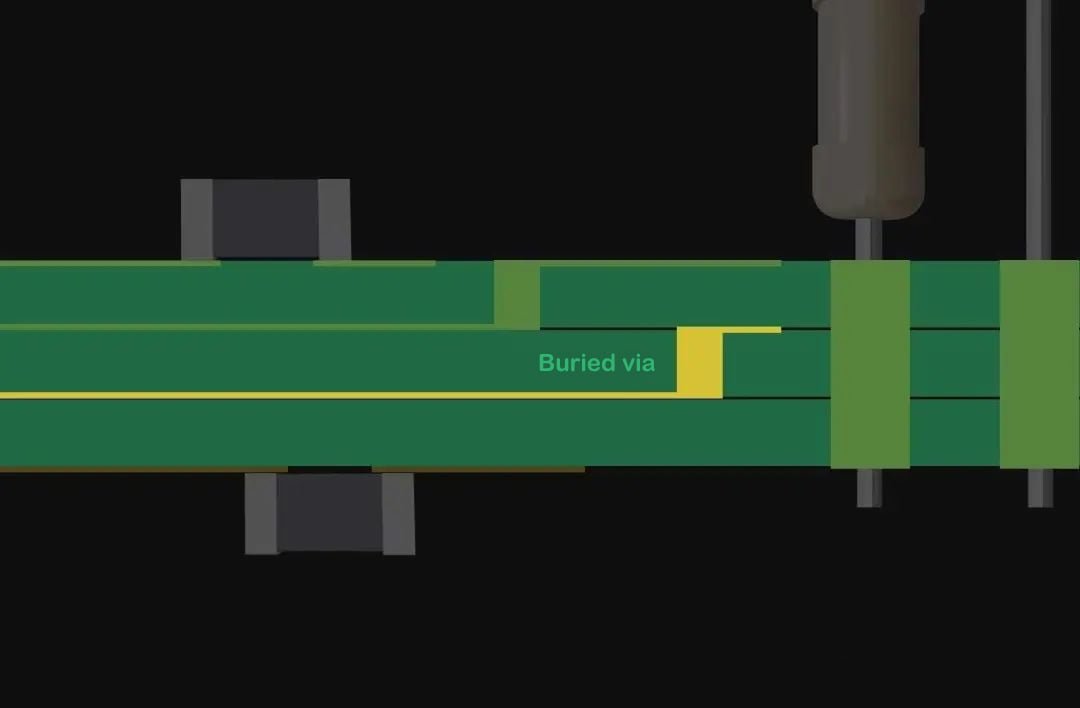

Buried Via

Buried vias are entirely hidden within the layers of the PCB, connecting two or more internal copper layers. They are suitable for high-density PCBs with limited space.

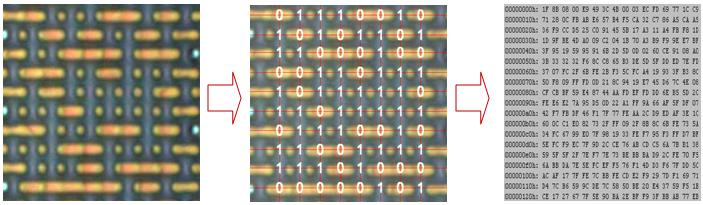

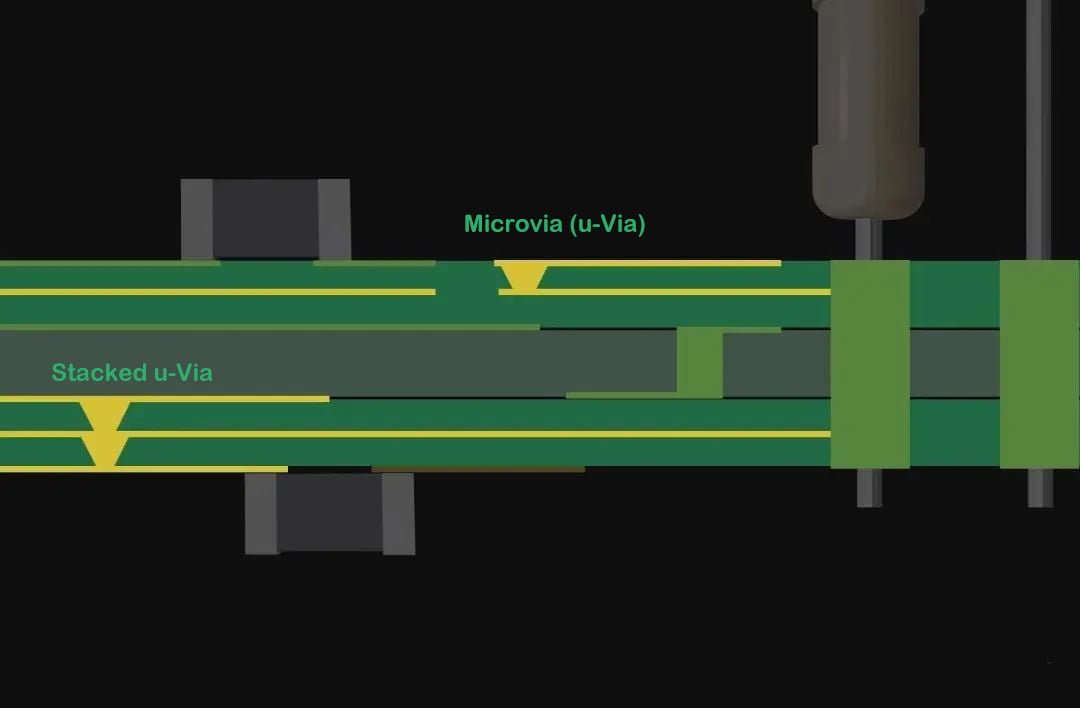

Microvia (uVia)

Microvias are very small through-holes used in high-density PCBs with limited space. They connect internal layers of the PCB and typically have a maximum diameter of 0.15 mm, a maximum aspect ratio of 1:1, and a maximum depth of 0.25 mm. They are commonly used in compact electronic products like smartphones.

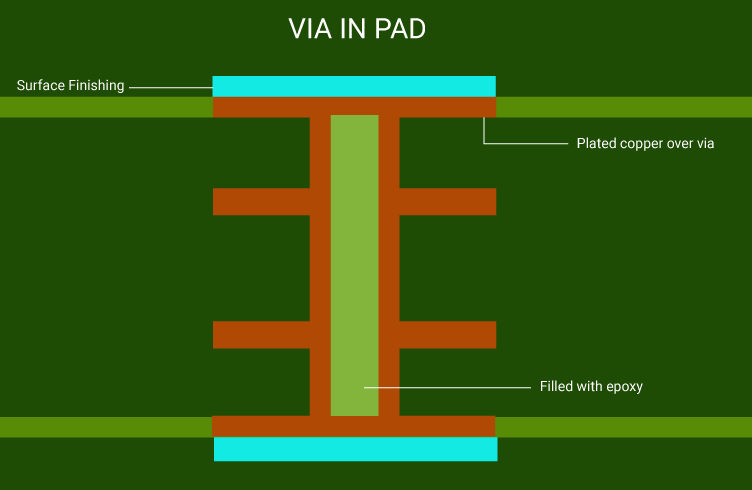

Via-in-Pad (VIP)

VIP technology allows vias to be placed within the solder pads of external components. It offers advantages like signal path expansion, eliminating the impact of inductance and capacitance, reducing PCB size, and accommodating smaller ground sizes. VIP is commonly used for BGA components.

PCB Via Processing

To improve PCB assembly yield or thermal performance, the vias are often subject to additional processing, including filling, capping, tenting, or covering.

Tented Via

Tented Via involves covering both ends of a via with non-conductive solder mask, effectively sealing the opening. This is popular when using dry film solder mask layers, as it effectively covers large holes without cracking.

Plugged Via

Plugged Via uses non-conductive epoxy resin to fill one or both ends of the via, preventing solder from flowing through during the soldering process. For effective plugging, the via’s diameter is typically limited to a maximum of 20 micrometers. Manufacturers often use solder mask layers to cover plugged vias.

Filled Via

Manufacturers may use non-conductive epoxy resin paste to fill regular or intruded vias. These filled vias are positioned a few micrometers away from the pads. For medium-density PCBs, this is a good compromise, as the presence of solder mask layers reduces the likelihood of solder bridging between vias and adjacent pads.

Conductive Filled Via

Some manufacturers use conductive paste to fill microvias, enhancing their conductivity. This filling can be epoxy resin mixed with copper or, in some cases, pure copper.

Functions of PCB Vias

PCB vias serve various functions in electronic circuits, including:

Signal Routing

Vias facilitate the path for signals to traverse between different signal layers, allowing components on one side of the board to communicate with those on the other side.

Power Distribution

Vias play a vital role in distributing power and ground connections between different layers, ensuring a stable power supply to all components.

Escape Routing

Larger surface mount (SMT) components mostly use through holes for escape routing. Microvias or blind vias are most commonly used for escape routing, but via-in-pad can be used in solid packages such as high pin count BGAs.

Component Connection

Through holes or blind holes can be used to provide multiple connections to the plane. For example, a strip of metal with stitched vias surrounds sensitive areas of the circuit, connecting it to the ground plane for EMI protection.

Heat Conduction

Vias can be used to conduct heat outward from the internal planar layers through which components are connected. Typically, thermal vias require dense blind or via holes that must be located in the pads of these devices.