Unleashing The Power Of Rigid-Flex PCB

Explore the "hybrid genius" technology that merges the robustness of rigid circuits with the adaptability of flexible ones, driving the innovation of next-generation electronics.

Start Exploring ↓Core Concepts: What is a Rigid-Flex PCB?

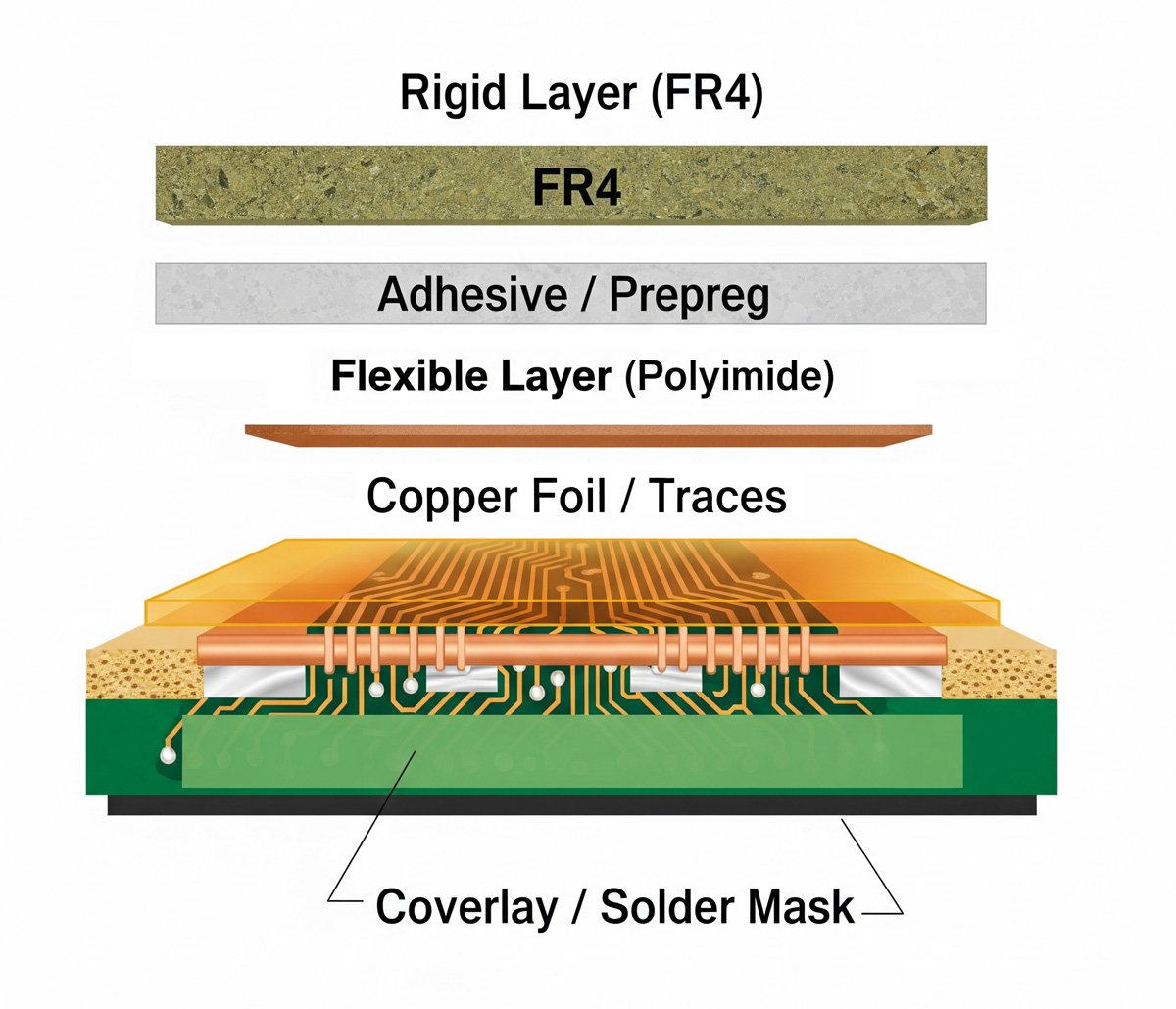

A Rigid-Flex PCB is a revolutionary combination of rigid and flexible printed circuit boards. This innovative technology merges the best of both worlds, offering the stability and durability of rigid PCBs with the flexibility and adaptability of flexible PCBs. The rigid sections are typically made from materials like fiberglass-reinforced epoxy (FR4), which provide a sturdy base for mounting components. These parts are excellent for supporting larger and heavier components, ensuring they remain firmly in place.

On the other hand, the flexible parts are crafted from materials such as polyimide or polyester films. These materials allow the PCB to bend, twist, and conform to various shapes and spaces, similar to how a flexible wire can be bent into different configurations. This flexibility enables designers to create more compact and complex electronic devices.

The true value of Rigid-Flex PCBs lies in their synergy—they solve design challenges that traditional rigid or flexible boards cannot address alone. This section delves into their basic composition and core advantages.

Interactive Structure Dissection

PCB Type Comparison

Seven Core Powers

These unique capabilities work together, making Rigid-Flex PCB a powerful tool for solving complex engineering problems. Click a card to learn about quantitative metrics and real-world cases for each power.

Technical Deep Dive

Explore the critical technical considerations and processes that enable the design, manufacturing, and long-term reliability of Rigid-Flex PCBs.

Trade-offs & Cost-Effectiveness

While the initial cost may be higher, does it mean it's not cost-effective? This section uses data visualization to reveal its true value over the entire product lifecycle.

Multi-Dimensional Strengths & Weaknesses

This radar chart visually compares the key attributes of Rigid-Flex PCBs. It highlights their exceptional strengths in reliability, space utilization, and signal integrity, while also showing their relative disadvantages in initial cost and manufacturing complexity.

Total Cost of Ownership (TCO) Analysis

This stacked bar chart demonstrates the total cost of ownership. It shows that while the initial manufacturing cost is higher, the savings from reduced assembly, testing, and long-term maintenance can result in a significantly lower overall TCO compared to traditional rigid PCB solutions.

Application Field Exploration

From everyday consumer electronics to cutting-edge aerospace, Rigid-Flex PCBs are everywhere. Select an industry to explore how this technology solves specific challenges.