What is Solder Paste?

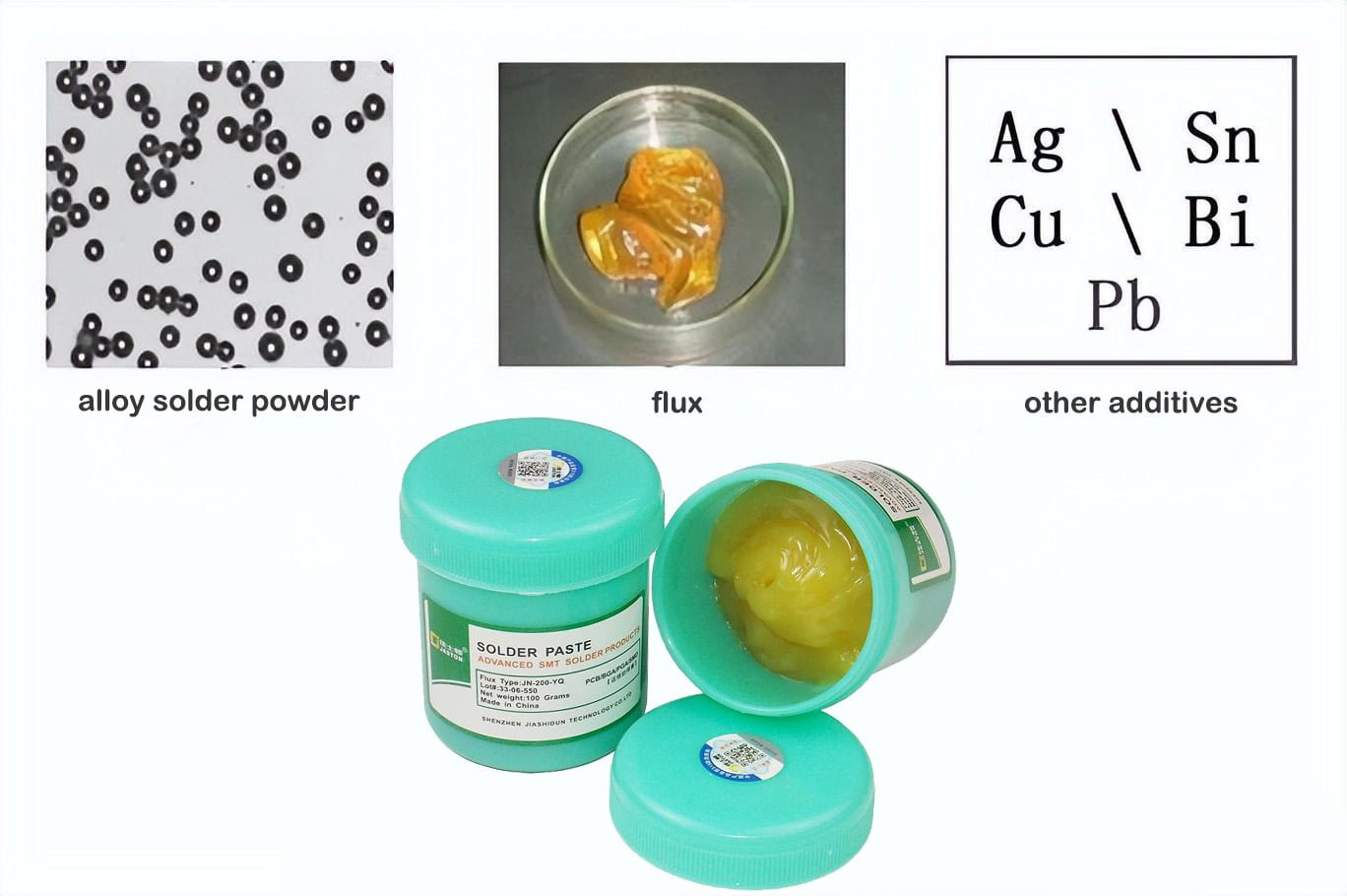

Solder paste, also known as solder cream or tin paste, is a mixture primarily used to bond metal components together. It has a complex composition, consisting of solder powder, flux, and other additives, depending on the specific requirements of the solder paste.

Solder paste possesses a certain level of viscosity, allowing it to adhere to electronic components at specific locations. As the temperature increases, the solder paste undergoes a process called reflow, where the solvents and additives evaporate, resulting in a permanent connection between the electronic components and the printed circuit board (PCB).

Composition of Solder Paste

Solder paste is mainly composed of alloy solder powder and flux, mixed and stirred well to form a paste mixture. The alloy solder powder accounts for 85% to 90% of the total weight, and the flux accounts for 10% to 15%.

Alloy solder powder

Alloy solder powder is made by spray method in inert gas, and the particle size of the powder is determined by grading. The shape of the solder powder is divided into spherical and indefinite, spherical suitable for printing. Commonly used alloy solder powder has two categories: lead and lead-free.

Leaded solder powders include tin-lead (Sn-Pb), tin-lead-silver (Sn-Pb-Ag), tin-lead-bismuth (Sn-Pb-Bi), etc. The most commonly used alloy composition is 63% Sn/37% Pb and 62% Sn/36% Pb/2% Ag.

Lead-free solder powders include tin a silver (Sn-Ag), tin-silver-copper (Sn-Ag-cu), etc., of which the most common alloy composition is 96.5% Sn/3.5% Ag and 93.6% Sn/4.7% Ag/1.7% Cu.

Flux

In solder paste, the paste flux is the carrier of the alloy powder. Its composition is basically the same as that of general-purpose fluxes. To improve the printing effect and thixotropy, thixotropic agents and solvents are sometimes added. Through the role of active agent in the flux, it can remove the surface of the soldered material and the oxide film of the alloy powder itself, so that the solder quickly spreads and adheres to the surface of the soldered metal. Flux composition on the expansion of the solder paste, wettability, collapse, viscosity changes, cleaning properties, solder bead spatter and storage life have a large impact.

Types of Solder Paste

Lead and Lead-free solder paste

Lead-containing solder paste consists mainly of Sn and Pb, such as Sn5/Pb95 or Sn10/Pb90.

Lead-free solder paste primarily consists of tin, silver, and copper, with lead content below 1000 ppm.

Low and high melting point solder paste

The most commonly used solder paste has a melting point ranging from 178 to 221°C. Depending on the type and composition of the metals used, the melting point of solder paste can be increased to over 250°C or reduced to below 150°C. Different solder paste melting points can be chosen based on the required soldering temperature.

R, RMA, and RA solder paste

Following the classification principle of general liquid flux activity, solder paste can be divided into three levels: non-active (R), mildly active (RMA), and active (RA).

According to the viscosity of solder paste

The viscosity of solder paste can vary greatly, typically ranging from 100 to 600 Pa·s, and can even exceed 1000 Pa·s. The selection depends on the specific dispensing process.

According to the cleaning method of solder paste

Solder paste can be classified into organic solvent cleaning, water-soluble, and no-clean types based on the cleaning method.

Organic solvent solder paste:

During the soldering process, this type of tin paste exhibits better “tinning speed” and provides good “soldering effects.” After the work is completed, there is more rosin residue on the surface of the PCB. Workers can use cleaning agents for washing. The PCB will be shiny with no residue, ensuring good insulation resistance and passing various electronic performance tests.

Water-soluble solder paste:

Due to excessive residue on the surface of the PCB caused by early manufacturing techniques, product quality and electronic performance were adversely affected. Cleaning processes used at that time mostly involved the use of CFCs, which are environmentally unfriendly and banned in many countries. In response to this, water-soluble solder paste emerged, allowing for cleaning after soldering and reducing product costs while meeting environmental requirements.

No-clean solder paste:

After soldering, the surface of the PCB is relatively smooth with minimal residue, eliminating the need for additional cleaning. It can undergo various electrical performance tests. This type of solder paste not only ensures soldering quality but also shortens the manufacturing process and improves efficiency.

Storage and Usage of Solder Paste

Storage:

Upon receiving solder paste, record the arrival time, shelf life, model, etc., and conduct acceptance inspection. If necessary, perform testing and verification according to the specifications provided by the supplier.

Each batch of solder paste should be stored separately, and the first-in-first-out principle should be followed when issuing.

Solder paste should be stored sealed in an environment at 5-10°C. High temperatures can cause a chemical reaction between the flux and the alloy solder powder, leading to increased viscosity and affecting printability. Low temperatures (below 0°C) can cause crystallization of the rosin in the flux, deteriorating the properties of the solder paste.

Usage:

Generally, solder paste should be taken out of the refrigerator one day in advance of use. It should be taken out at least 2 hours in advance. The solder paste container should be opened only when the solder paste has reached room temperature. Opening it at low temperatures can lead to absorption of moisture, resulting in solder balls during reflow. Avoid using tools such as hot air blowers or air conditioning to accelerate the warming of the solder paste.

After opening the solder paste, inspect its surface. If it has become hardened or if flux separation has occurred, special treatment is required, and it should not be used. If the surface of the solder paste appears normal, it should be slowly and evenly mixed using a mixer or by hand before use. If the solder paste is too viscous to pass smoothly through the stencil apertures or a quantitative dispenser, a suitable diluent should be added and thoroughly mixed before use.

After taking out the solder paste, make sure to tightly seal the container to prevent the flux from evaporating.

Application of Solder Paste:

There are three main methods for applying solder paste: syringe dispensing, screen printing, and stencil printing. Syringe dispensing involves using a specialized dispenser or manual application with solder paste in a barrel shape, which is suitable for small-batch production. Screen printing utilizes a mesh made of nylon or stainless steel wires with patterns engraved on it to transfer the solder paste onto the PCB. It is generally suitable for low-to-medium-density assembly in small-to-medium batch production. The most commonly used method is stencil printing, which uses brass or stainless steel sheets with engraved patterns to apply the solder paste onto the PCB. Here, we will focus on the usage method when using stencil printing.

- Determine the initial amount of solder paste to be applied to the stencil based on the board size and the number of solder joints. Generally, start with 200-300g of solder paste (ensuring its rollability), and add a little more after printing for a while.

- The ideal temperature for solder paste printing is 25±3°C, with a relative humidity of 60%. Higher temperatures can cause the solder paste to absorb moisture and result in solder balls during reflow.

- If the solder paste remains on the stencil for more than 30 minutes without use, it should be stirred using the mixing function of a screen printer before application.

- The key to applying solder paste onto the PCB is to ensure accurate placement on the solder pads of the components. If the application is inaccurate, the solder paste must be wiped off and reapplied (do not use alcohol for wiping no-clean solder paste).

Recycling:

If there is a long interval between usage, the solder paste should be returned to the container and tightly sealed until it is used again. In principle, solder paste should be used within the same day after opening. Solder paste scraped back from the stencil should also be sealed and refrigerated.

Other considerations:

Other printed solder paste of the circuit board to install components in time, more than time should be solder paste cleaning after re-printing. Finish mounting the circuit board as far as possible within 4 h to complete the reflow soldering. Re-flow solder the circuit board, needs the cleaning should complete the cleaning in the same day, prevents the solder paste residue to the circuit to produce the corrosion.

How to Choose Solder Paste?

Choice of Flux Activity

Flux is one of the main components of solder paste. Solder paste can utilize three different types of flux: R flux (rosin flux), RMA flux (moderately activated rosin flux), and RA flux (fully activated rosin flux). The activators in moderately activated and fully activated rosin fluxes help remove oxide layers and other surface contaminants from the metal surface, facilitating the wetting of solder to the surface-mounted pads and component leads or pins. The choice of flux activity depends on the cleanliness of the surface-mounted printed circuit board and the freshness of the components. Generally, medium activity can be chosen, with the option of high activity or non-activated levels if necessary, or even super-activated levels.

Viscosity Selection

The viscosity of solder paste should be selected based on the application method, and the viscosity of solder paste depends on the characteristics of the application process (such as screen mesh size, squeegee speed, etc.). For screen printing, a typical viscosity range is 100-300Pa. For stencil printing, a higher viscosity should be chosen, ranging from 200-600Pa. For dispensing applications, the viscosity should be around 100-200Pa.

Metal Content Selection

The metal content in solder paste determines the size of solder joints. The size of solder joints increases with the increase in metal percentage. However, even a slight change in metal content at a given viscosity can have a significant impact on the quality of solder joints. For example, with the same solder paste thickness, a 10% change in metal content can shift the joint from excessive to insufficient. Generally, solder paste used for surface-mount components should have a metal content of 88% to 90%.

Solder Powder Particle Size Selection

The shape of solder powder particles determines the oxygen content and printability of the solder paste. Spherical powder particles are superior to elliptical ones, and smaller spherical particles have lower oxidation capability.