We have advanced equipment to support rapid PCB prototyping. Depending on the situation, the entire production process takes about one to three weeks. The prototype is first tested in the laboratory, and we will send the test report to the customer for analysis. If necessary, the design will be re-examined and a second prototype will be made.

We will strictly control the prototype production process, standardize the requirements of each stage of prototype production, effectively control the punctuality rate, prototype quality and effective records of the prototype, and deliver the most suitable technical requirements and the most economical products to customers.

What Is Rapid PCB Prototyping?

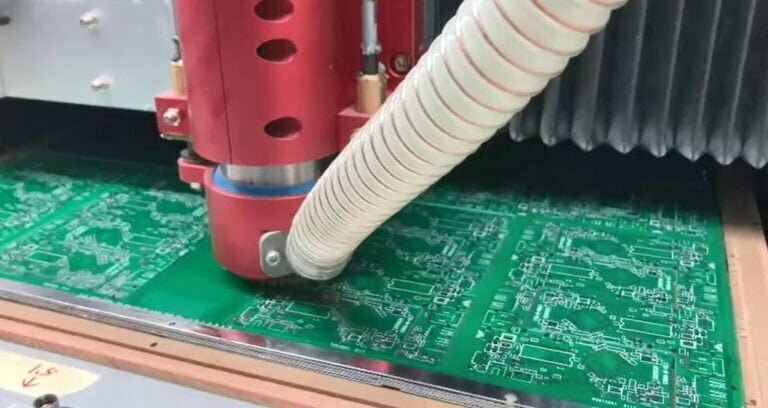

Rapid PCB prototyping is a fast and effective method of creating a physical circuit board using computer-aided design (CAD) software. It enables designers to rapidly produce PCBs with high precision and accuracy, allowing them to quickly test and validate their designs. Rapid PCB prototyping typically involves the use of a computer-controlled milling machine that is programmed with a CAD file to cut and shape the PCB. This process can be used to create a single board or multiple boards in a short period of time, allowing for faster design cycles and quicker product launch. The process can also reduce the cost and time associated with traditional PCB production. Examples of rapid PCB prototyping can include laser cutting and drilling, CNC milling, and 3D printing.

Division of responsibilities before PCB Prototyping

The person in charge of the development department: responsible for the review of the “Prototype Demand List”, the confirmation of the delivery date, the inspection of the prototype function and the prototype output, the control of the prototype process, and the follow-up of the prototype progress.

Prototype unit: responsible for the production of prototypes, the collection of materials required for prototype production, the customization of wire materials, the requisition of materials, and the maintenance of prototypes.

Test group: responsible for the functional test of the prototype, loading test, noise test, high and low temperature test, appearance and packaging inspection.

Software Engineer: Responsible for software design and debugging.

Hardware Engineer: Responsible for hardware design and maintenance.

Rapid PCB Prototyping Process

1. Submit the Request

The prototype demand customer fills in the “Prototype Demand Form” to the development department. The “Prototype Demand Form” must indicate the customer’s name, the prototype demand list number, the product name, the number of prototypes, the date of demand for the prototype, the number and color of the remote control, the needs If the function is different from the existing model, please indicate the required function. (Note: The “Prototype Demand Form” must be signed and confirmed by the customer who needs the prototype.)

2. Comfirm the Demand

After the development department receives the prototype request form, it must confirm the delivery date and prototype function. If there is any problem, it must reply in time and negotiate with the same machine demand customer. If necessary, the prototype demand customer should change the “Prototype Demand List” if there is no problem , the person in charge of the development department signed and handed over the production of the sample unit.

3. Sourcing Raw Material

After the prototype group receives the “Prototype Demand Form”, the number of materials to be picked is 1-5 sets more than the required quantity, and the purchase requisition should be filled in in time when the required materials are lacking.

4. Design Prototype

For prototype design, software engineers design software, hardware engineers design circuit and PCB LAYOUT.

5 Prototype output

The hardware engineer is responsible for the schematic diagram, component list production and documentation. Software engineers are responsible for the numbering and archiving of source and object code.

The test team tests and fills in the “Test Record” according to the requirements of the “Prototype Demand Sheet”, and the appearance inspection is based on the “Appearance Inspection Standard for the Whole Machine”. New product prototypes need to select 1-5 units for high and low temperature test, loading test, noise test, and fill in the “Test Record”, “Noise Test Report”, “High and Low Temperature Test Report”, and the machine that has done the noise test. Can not sample.

In the process of prototype production, if it is found that the prototype cannot be completed on time as scheduled, the person in charge of the development department shall notify the customer who needs the prototype in time, and negotiate with the person in charge of the same machine unit.

6. Packaging the Prototype

After the prototype is completed, provide manuals and installation circuit diagrams, pack and pack according to packaging requirements, and must be reviewed by the person in charge of the development department, and fill in the corresponding “Prototype Performance/Function Confirmation Form”.

The “Prototype Demand Sheet”, “Prototype Performance/Function Confirmation Form”, and the test reports that have been done (“Test Record”, “Noise Test Report”, “High and Low Temperature Test Report”) shall be archived by the Development Department for future reference . The new product prototype also needs to archive the following materials: schematic diagram, PCB board diagram, soldering diagram, wire diagram, installation circuit diagram, manual, CPU source program, object code, etc. For prototypes made by modifying the original products, if the above technical data are changed, the changed data should also be archived.

7 Prototype sign-off

The Development Department shall fill out the “Prototype Signing List” and “Prototype Performance/Function Confirmation Form”, and deliver it to the relevant prototype demand customers together with the produced prototype to sign for receipt.

8. Prototype complaints and defective product handling

Prototype requirements Customers should test after receiving the prototype. If any software or hardware problems are found in the test, they should record them in detail and communicate to the development department in writing. The problem happened again.