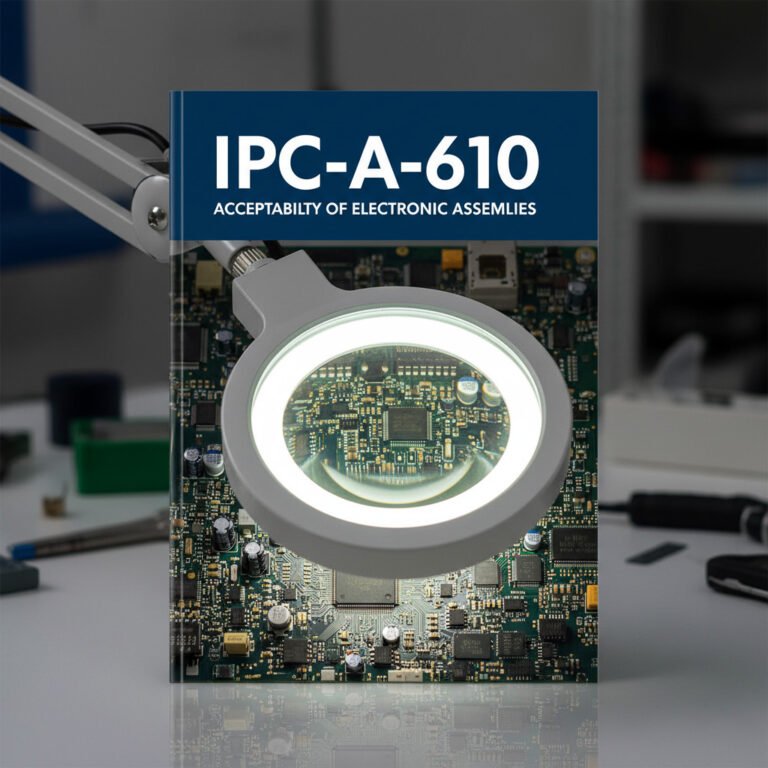

IPC-A-610: The Ultimate Guide to Electronic Assembly Acceptance Standards

Complete guide to IPC-A-610: The Acceptability of Electronic Assemblies. Learn about classes, certification, requirements, and how it compares to J-STD-001.

Schematic & Gerber restoration

MCU/CPLD code restore access & backup

1:1 exact hardware replication

BLE & Classic BT wireless solutions

Precision PID & thermal management

High-efficiency motor drive control

Industrial RS485/RTU communication

Custom STM32/ESP32 firmware & HW

Calculate the PCB trace width based on temperature rise, current, and copper thickness (IPC-2152).

Explore the essential techniques for assembling and soldering printed circuit boards (PCBs). This category includes comprehensive guides on different soldering methods (wave soldering, hot air solder leveling, hand soldering), tips for effective PCB assembly, and advanced soldering techniques. Articles also address troubleshooting common soldering issues and best practices for achieving reliable, high-quality connections on your PCBs.

Complete guide to IPC-A-610: The Acceptability of Electronic Assemblies. Learn about classes, certification, requirements, and how it compares to J-STD-001.

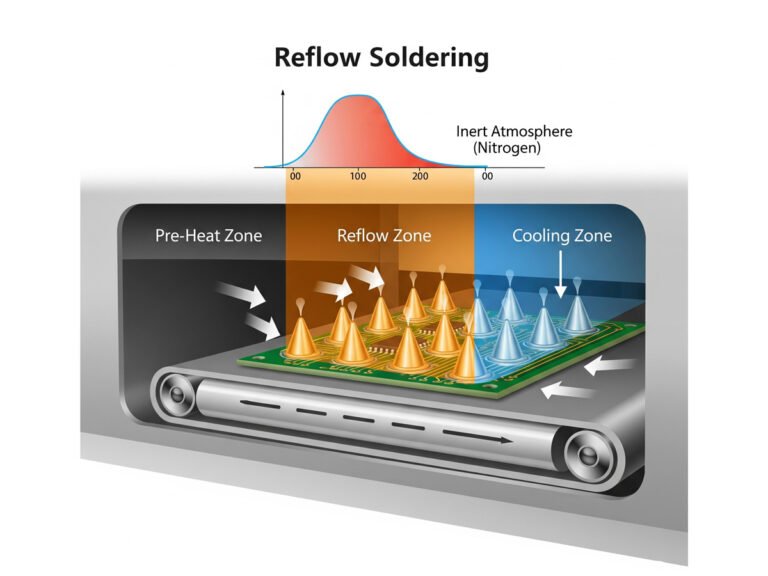

Core Concepts Process Flow Troubleshooting Comparison FAQ What is Reflow Soldering? This section lays the groundwork by explaining the fundamental “what,” “why,” and future of reflow soldering in modern electronics manufacturing. It also highlights its widespread applications. Reflow soldering is

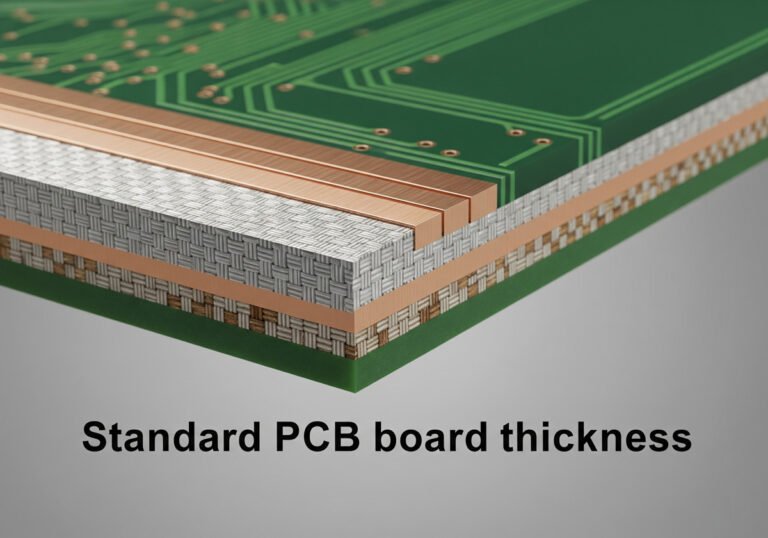

A comprehensive guide to standard PCB board thickness. Learn its impact on mechanical stability & electrical performance, and choose the right one for your projects.

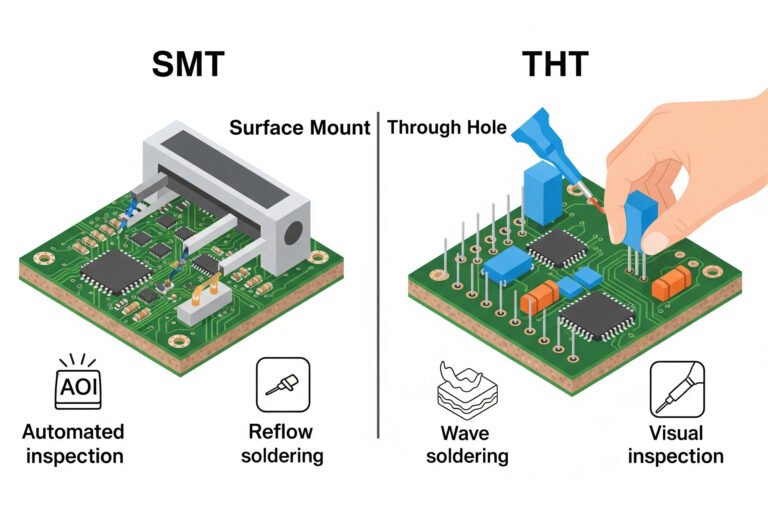

Discover the key differences between Surface Mount Vs Through Hole technologies, their advantages, and when to use each for optimal electronic assembly.

PCB mounting and soldering are essential skills for every electronics engineer. Learn how to avoid common pitfalls and achieve successful PCB assembly. Explore component placement, soldering techniques, and how to troubleshoot issues.

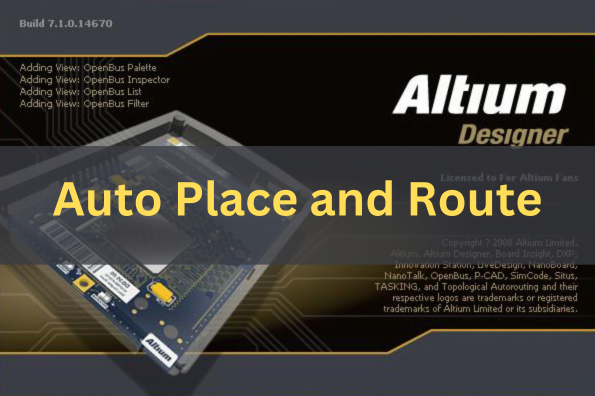

When designing a PCB, in order to improve efficiency, we need to learn how to automatically place and route our projects. In this tutorial, we will introduce the auto place and route in Altium Designer. Auto Placing Components 1. Select

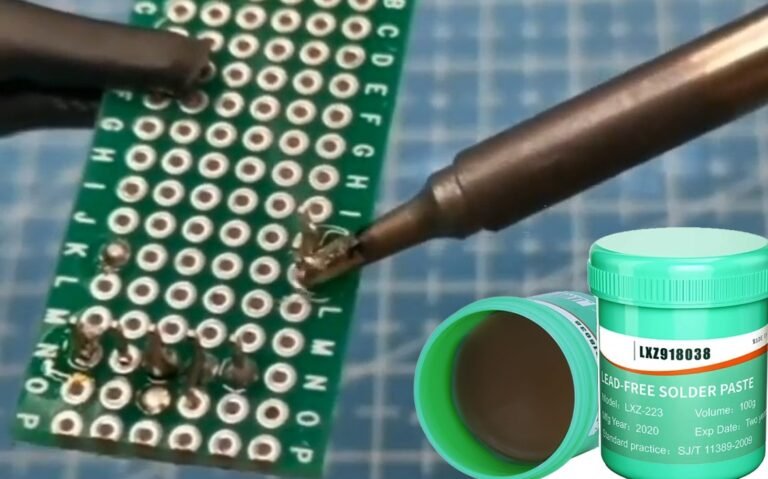

Choose solder paste: alloy composition (Sn-Pb, lead-free), viscosity, and stencil printing. Tips for SMT assembly and reflow soldering. Best practices inside!

Choosing the right flux: rosin, water-soluble, and no-clean types. Learn how flux improves soldering quality and prevents defects. Safety tips inside!

Wave soldering for through-hole components: process steps, flux application, and defect prevention. Tips for optimizing throughput and quality. Expert guide here!

Learn to avoid solder wicking: causes (overheating, poor flux), prevention tips, and repair methods. Essential for clean PCB soldering. Step-by-step guide!