As a hardware engineer, I understand the importance of cooling Printed Circuit Boards (PCBs) for optimal performance. Without proper cooling, your PCBs can suffer from a range of issues like reduced efficiency and even complete failure. But cooling your PCBs doesn’t need to be a complicated process, if you know the right techniques.

In this blog article, I’ll cover the basics of cooling your PCBs, the various types of cooling techniques, and some tips to help you get the most out of your cooling setup. So let’s dive in!

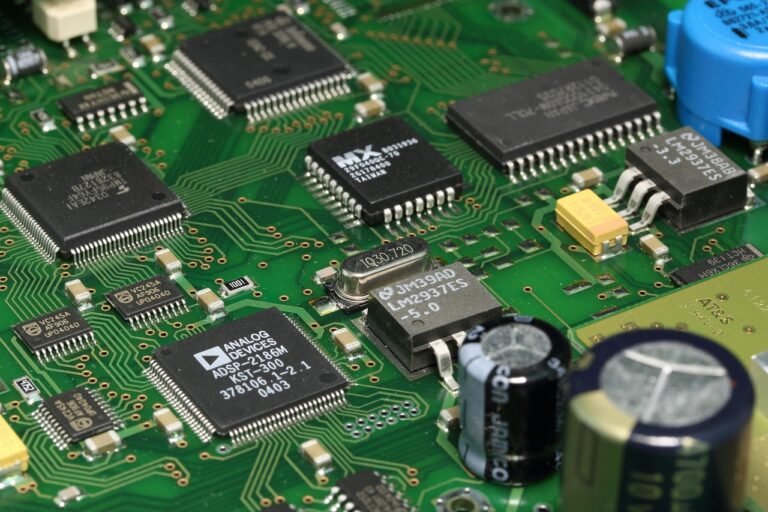

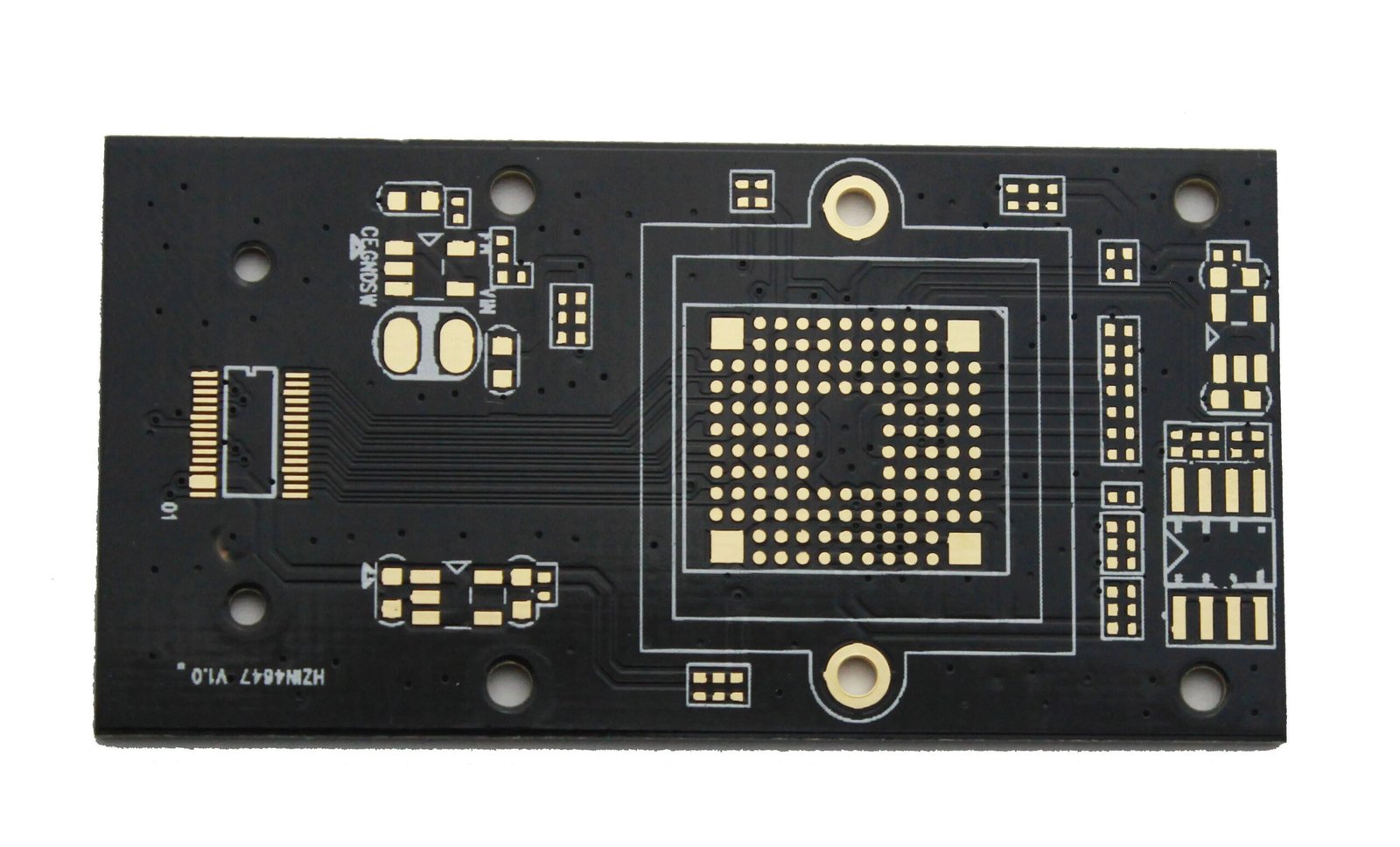

Introduction to PCB Cooling

The primary purpose of cooling your PCBs is to reduce the risk of overheating, which can lead to significant damage and performance issues. Heat is generated by the components on the boards, and the more powerful the components the more heat is generated. When the temperature of the PCBs reaches a certain level, the components can become damaged or even fail completely.

This is why it’s important to cool your PCBs properly. There are a variety of cooling techniques available, from passive cooling solutions to active cooling solutions. The type of cooling technique you choose will depend on the specific needs of your PCBs and the environment in which they will be operating.

Benefits of Cooling PCBs

Cooling your PCBs has a number of benefits, including increased efficiency, improved reliability, and longer life. When the components on the boards are cooler, they run more efficiently, resulting in improved performance. Additionally, components that are kept cool are less likely to fail, resulting in improved reliability. And finally, components that are kept cool will last longer, resulting in fewer replacements and lower maintenance costs.

Types of Cooling Techniques

There are several types of cooling techniques available, each with its own advantages and disadvantages. Some of the most common cooling techniques include:

- Heat Sinks

- Heat Spreaders

- Airflow

- Thermally Conductive Adhesives

- Liquid Cooling

We’ll take a closer look at each of these cooling techniques in the sections below.

Heat Sinks

Heat sinks are the most common type of cooling technique for PCBs. They are typically made of metal and are designed to absorb and dissipate heat away from the components on the boards. Heat sinks are attached to the components with screws or clips, and the heat is dissipated into the air. Heat sinks are a relatively inexpensive cooling method, but they are not as effective at cooling as some of the other techniques.

Heat Spreaders

Heat spreaders are similar to heat sinks, but they are designed to spread the heat more evenly across the board. Heat spreaders are usually made of a combination of metal and plastic, and they can be attached to the components with screws or clips. Heat spreaders are more expensive than heat sinks, but they are more effective at cooling PCBs due to their ability to spread the heat more evenly.

Airflow

Airflow is another popular cooling technique for PCBs. It involves using fans to blow air across the components, which helps to dissipate the heat away from the boards. Airflow is an effective cooling method, but it requires a lot of energy to power the fans and can be noisy. Additionally, airflow is not always practical if the components are in a confined space or if the fan is too large.

Thermally Conductive Adhesives

Thermally conductive adhesives are a relatively new cooling technique for PCBs. They are designed to transfer heat away from the components by using a special adhesive material. Thermally conductive adhesives are a great option for cooling PCBs, but they can be expensive and require careful application. Additionally, if not applied correctly, the adhesive can cause damage to the components.

Liquid Cooling

Liquid cooling is the most effective cooling technique for PCBs, but it is also the most expensive and complex. Liquid cooling involves running a coolant such as water or oil through a network of pipes and radiators to cool the components on the boards. Liquid cooling is the most efficient cooling method, but it requires a lot of setup and maintenance and can be very noisy.

PCB Cooling Tips

Here are some tips to help you get the most out of your cooling setup:

- Make sure to choose the right cooling technique for your needs. Consider the size of your PCBs, the components on the board, and the environment in which they will be operating.

- Make sure that your cooling components are properly installed and secured. Poorly installed components can lead to poor performance and even damage to the components.

- Make sure to regularly maintain your cooling setup. This includes cleaning the components and checking for leaks and other issues.

- Make sure to monitor the temperature of your PCBs. Keeping an eye on the temperature will help you identify any issues with your cooling setup.

Conclusion

Cooling your PCBs is an essential part of maintaining optimal performance. There are a variety of cooling techniques available, from passive solutions like heat sinks and heat spreaders to active solutions like airflow and liquid cooling. By following the tips outlined above, you can ensure that your PCBs are cooled properly and running at their best.

PCB cooling is an important step in ensuring that your boards are performing at their peak. It’s important to choose the right cooling technique for your needs and to regularly maintain your cooling setup. By doing so, you can ensure that your PCBs are cooled properly and running at their best.

So if you’re looking to cool your PCBs, make sure to check out the different cooling techniques discussed in this article. With the right setup, you can make sure that your PCBs are running at their best and that they are protected from the risks of overheating.

I hope this blog article has given you a better understanding of cooling your PCBs. If you have any questions or need more advice, feel free to reach out and I’ll be happy to help.