Understanding the industry standard for electrical testing of unpopulated printed circuit boards (PCBs) to ensure reliability and prevent costly failures.

What is IPC-9252?

A foundational standard for PCB quality assurance.

Purpose

To establish a baseline for detecting electrical defects in bare PCBs before component assembly. It verifies the integrity of the board's conductive patterns.

Scope

The standard covers requirements for continuity and isolation testing, defining test parameters, conditions, and pass/fail criteria for different levels of board complexity and reliability.

Importance

Testing to IPC-9252 is crucial. It catches fabrication defects like opens and shorts early, preventing expensive rework or field failures after components are mounted.

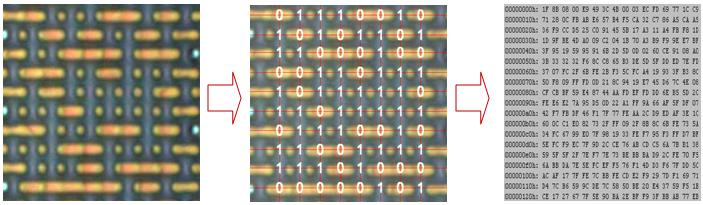

Core Testing Concepts

IPC-9252 revolves around two fundamental tests.

Continuity Test

Verifies that electrical paths (traces and planes) that are designed to be connected have a complete, unbroken circuit with resistance below a specified limit.

Isolation Test

Ensures that circuits and conductive features that are not meant to be connected are properly isolated from each other, with resistance above a specified limit.

IPC Performance Classes

The standard defines testing stringency based on the end-product's application.

Class 1: General Electronic Products

Includes most consumer electronics where the primary requirement is the function of the completed assembly. Cosmetic imperfections are not a major concern. Testing is the least stringent.

Examples: Toys, remote controls, some home appliances.

Class 2: Dedicated Service Electronic Products

Requires continued performance and extended life. Uninterrupted service is desired but not critical. Boards are built to a higher standard of reliability than Class 1.

Examples: Laptops, televisions, smartphones, industrial equipment.

Class 3: High Performance/Harsh Environment Products

For products where continued high performance or performance-on-demand is critical. Equipment downtime cannot be tolerated, and the end-use environment may be uncommonly harsh. Testing is the most rigorous.

Examples: Medical life-support systems, aerospace, automotive safety, military devices.

Comparison of Test Methods

Two primary methods are used for IPC-9252 testing.

| Feature | Flying Probe Tester | Fixture Tester (Bed of Nails) |

|---|---|---|

| Initial Cost | Low (no custom fixture) | High (requires custom fixture per design) |

| Per-Board Cost | Higher | Lower (at high volume) |

| Test Speed | Slower (probes move sequentially) | Very Fast (all points tested at once) |

| Best For | Prototypes, low volume, high-mix designs | High volume, mature production runs |

| Flexibility | High (easy to change test program) | Low (new fixture needed for design changes) |

Interactive Defect Explorer

Click the pulsing markers to learn about common PCB defects found by IPC-9252 tests.

Select a defect

Click a numbered marker on the PCB diagram to see details about a specific fabrication defect.

Frequently Asked Questions

While not legally mandatory, it is an industry-accepted standard. Most customers, especially for Class 2 and 3 products, require their PCB suppliers to test boards according to IPC-9252 to ensure quality and reliability.

Revisions like 'A' and 'B' update the standard. IPC-9252B is the current version, introducing more nuanced test methods and updated voltage requirements for testing high-density interconnect (HDI) boards and microvias, reflecting advances in PCB technology.

No. IPC-9252 is specifically for electrical defects (shorts, opens). It does not detect cosmetic issues, delamination, incorrect layer stackup, or dimensional errors. These require other inspection methods like Automated Optical Inspection (AOI) and X-ray.