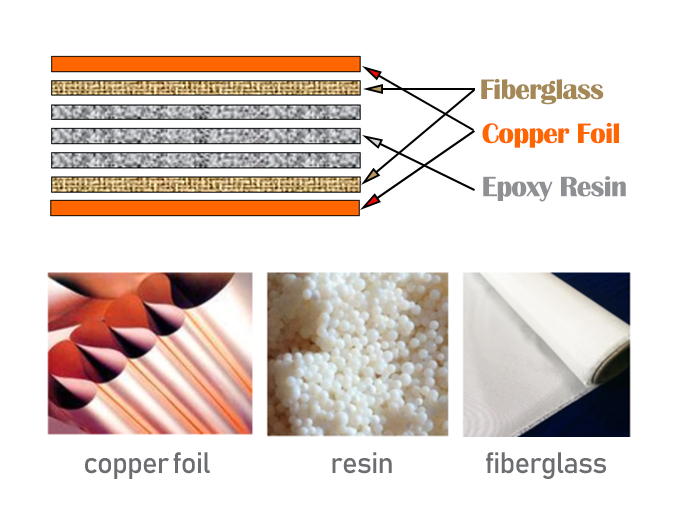

Copper Clad Laminate (CCL) is a fundamental material in the production of printed circuit boards (PCBs). It consists of an insulating substrate, usually made from materials like paper, fiberglass fabric, or composite materials, impregnated with resin and bonded to copper foil through heat pressing. CCL plays a vital role in PCBs by ensuring electrical conductivity, insulation, and mechanical support, ultimately affecting the transmission speed, energy loss, and characteristic impedance of the PCB. As a key material in the electronics industry, CCL is extensively used in various fields such as computers, mobile phones, telecommunications, aerospace, and automotive industries.

Structure of Copper Clad Laminate

The CCL structure consists of three main components: Copper foil, Substrate, Adhesive.

Copper Foil

Copper foil is a critical material for CCL production, providing high electrical conductivity and good solderability. The copper foil must have a purity of at least 99.8% and a thickness variation of no more than ±5µm. Thinner copper foils are ideal for manufacturing high-density PCBs with complex circuits.

Substrate

The insulating layer is made from synthetic resin and reinforcing materials. Common resins include phenolic, epoxy, and PTFE. Reinforcing materials such as paper or fabric determine the mechanical properties of the substrate, such as resistance to soldering and bending strength.

Adhesive

The adhesive ensures that the copper foil is firmly bonded to the substrate. The adhesive’s properties are crucial in determining the laminate’s peel strength and overall quality.

Types of Copper Clad Laminate

CCLs can be classified based on various criteria, including mechanical rigidity, resin type, insulation materials, and fire resistance:

| Category | Description |

|---|---|

| By Rigidity | Rigid CCL, Flexible CCL |

| By Resin Type | Phenolic Resin CCL, Epoxy Resin CCL, and Polyimide Resin CCL |

| By Insulating Material | Organic Resin-based CCL, Metal-based CCL, Ceramic-based CCL |

| By Thickness | 0.8mm to 3.2mm, less than 0.78mm (without copper) |

| By Fire Resistance | UL94 standards, UL-94V0 (highest level) |

| By Thermal and Dielectric Properties | High Tg CCL, Low Dk/Low Df CCL |

Copper Clad Laminate Materials

Copper Foil

The primary conductive material in CCLs, copper foil can be electrodeposited (ED) or rolled-annealed (RA). ED copper is typically used in rigid PCBs, while RA copper is common in flexible PCBs.

Resin Materials

- Epoxy Resin: The most common resin used for CCL due to its excellent electrical insulation, heat resistance, and mechanical properties.

- Polyimide: Known for higher thermal and mechanical stability, often used for high-performance or high-temperature applications.

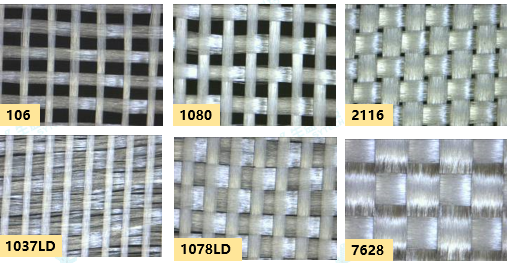

Fiberglass Fabric

Fiberglass provides excellent mechanical strength, electrical insulation, and thermal stability. Various types of fiberglass fabric, such as 106, 1080, and 2116, are used based on the required application, including high-frequency circuits.

Production Process of Copper Clad Laminate

The production process of CCL involves several key steps:

- Resin Preparation: The resin is mixed to the desired consistency.

- Application of Resin: The resin is applied to the reinforcing material.

- Lamination: The resin-coated material is layered with copper foil and subjected to heat and pressure to bond them together.

- Cutting and Inspection: After lamination, the CCL is cut to size and inspected for quality.

The overall process ensures that the copper foil is securely bonded to the substrate, resulting in a strong, electrically conductive laminate that forms the foundation for PCB manufacturing.

Future Trends in Copper Clad Laminate Industry

The CCL industry is evolving in response to various technological advancements and environmental considerations:

Lead-Free and Halogen-Free: Due to environmental regulations, especially in the EU, the demand for lead-free and halogen-free CCLs has surged. These materials require higher temperatures for soldering, which poses challenges in terms of thermal stability and manufacturing techniques.

High-Frequency and High-Speed Applications: With the rise of 5G and other high-speed communication technologies, there is a growing demand for CCLs with low dielectric constant (Dk) and low dissipation factor (Df). These properties are essential for maintaining signal integrity in high-speed circuits.

Lightweight and Thin Materials: As consumer electronics continue to evolve, there is an increasing need for thinner, lighter, and more compact CCLs, especially in devices like smartphones and wearables.

Conclusion

Copper Clad Laminate (CCL) is an indispensable material in PCB manufacturing, with its composition and properties significantly impacting the performance and reliability of electronic devices. As technology advances, CCLs are continuously improving to meet the demands of high-speed, high-frequency applications, while also addressing environmental concerns. The future of CCLs will likely focus on innovations in material properties, manufacturing processes, and environmental sustainability.