Electronic Manufacturing Services (EMS) are vital in today’s tech-driven world. They encompass a range of processes from design to distribution.

These services are essential for companies looking to streamline production and reduce costs. EMS providers offer expertise and efficiency that many businesses rely on.

Contract manufacturing is a key aspect of EMS. It allows companies to outsource production to specialized manufacturers, enhancing flexibility and scalability.

Supply chain management is integral to EMS. It ensures smooth procurement, production, and distribution, which are crucial for timely product delivery.

This guide will explore the benefits, processes, and innovations in electronic manufacturing services.

What Are Electronic Manufacturing Services (EMS)?

Electronic Manufacturing Services (EMS) refer to a comprehensive suite of processes involved in producing electronic components and products. EMS providers are specialized companies that handle everything from design and assembly to testing and distribution.

They play a crucial role in the modern electronics industry by offering end-to-end manufacturing solutions.

Typically, EMS providers offer a wide range of services. These services include:

- PCB Assembly: Creating circuit boards essential for electronics.

- System Assembly: Building complete electronic products ready for market.

- Testing and Quality Control: Ensuring product functionality and reliability.

- Logistics and Distribution: Managing product delivery and return processes.

EMS providers offer turnkey solutions, meaning they can manage an entire product lifecycle. This ranges from initial design to final delivery. By leveraging EMS, companies can tap into specialized expertise and advanced technologies. This leads to improved product quality and reduced production costs.

The collaboration between Original Equipment Manufacturers (OEMs) and EMS companies is vital. It ensures that products meet market demands and industry standards, paving the way for innovation and growth.

Key Services Offered by EMS Providers

EMS providers offer a variety of essential services tailored to meet diverse needs in the electronics industry. These services encompass everything from initial design phases to post-production support. By relying on EMS providers, companies benefit from specialized expertise and streamlined processes.

One of the fundamental services provided is PCB Assembly. This involves designing and building printed circuit boards, which are crucial for electronic devices. In addition to PCB Assembly, EMS providers offer Prototyping Services. This allows companies to test product concepts before full-scale production.

A comprehensive list of key services includes:

- Box Build Assembly: Final assembly of complex products.

- Component Sourcing: Procuring parts for manufacturing.

- Test Solutions: Verifying product performance and quality.

- After-Sales Support: Managing repairs and customer service.

System Integration is another critical service offered by EMS companies. It ensures that various components work seamlessly within the finished product. This service extends to software installations and hardware compatibility checks.

Additionally, many EMS providers engage in logistical support, managing the intricate supply chain. This includes warehousing, packaging, and distributing finished products to end consumers. These comprehensive services enable businesses to focus on innovation and market strategies while EMS providers handle manufacturing complexities.

The Role of Contract Manufacturing in EMS

Contract manufacturing plays a pivotal role within the realm of Electronic Manufacturing Services (EMS). This approach allows companies to outsource production to specialized manufacturers, optimizing operations. By leveraging contract manufacturing, businesses can focus more on core competencies, such as R&D and marketing.

EMS providers offer a range of contract manufacturing solutions. This involves taking over the entire production process from design to delivery. Such services are invaluable for companies without in-house manufacturing capabilities. Ultimately, this partnership enables organizations to achieve more efficient and cost-effective production.

Key aspects of contract manufacturing in EMS include:

- Cost Reduction: Lowering production expenses through economies of scale.

- Access to Expertise: Utilizing specialized manufacturing knowledge and skills.

- Flexibility: Scaling production volumes based on demand fluctuations.

Collaborating with EMS providers through contract manufacturing helps companies to introduce new products rapidly. This partnership ensures quicker time-to-market, a critical factor in staying competitive within fast-paced industries. The expertise and infrastructure provided by EMS companies contribute significantly to the overall success and innovation of electronic products.

EMS and Supply Chain Management

Electronic Manufacturing Services (EMS) is integral to effective supply chain management. EMS providers streamline procurement, production, and distribution processes, ensuring efficient delivery. This integration supports companies in maintaining a smooth and responsive supply chain.

The collaboration between EMS and supply chain management simplifies logistical challenges. EMS providers typically possess robust networks of suppliers and partners. This connectivity ensures reliability in sourcing materials and components essential for production.

Key elements of supply chain management in EMS include:

- Timely Delivery: Efficient logistics ensuring on-time shipments.

- Inventory Management: Optimizing stock levels to prevent shortages.

- Supplier Coordination: Effective communication and collaboration across the supply chain.

EMS companies enhance supply chain resilience by mitigating disruptions. Their expertise allows for quick adjustments to changing demands and market conditions. Organizations benefit from the adaptability and resources provided by EMS in maintaining efficient global operations. This synergy creates a responsive, flexible supply chain ready to meet today’s manufacturing challenges.

Benefits of Outsourcing to EMS Providers

Outsourcing to Electronic Manufacturing Services (EMS) offers significant advantages for companies. By leveraging EMS expertise, businesses can focus on core competencies rather than production complexities. This shift allows companies to allocate more resources to areas like R&D and marketing.

One of the major benefits is cost efficiency. EMS providers enable companies to save on labor costs and investment in expensive manufacturing equipment. Additionally, they offer economies of scale that individual companies might struggle to achieve.

Key benefits of outsourcing to EMS include:

- Cost Reduction: Lower operational and labor costs.

- Focus on Core Competencies: Redirect resources to innovation and growth.

- Access to Expertise: Leverage advanced technologies and skilled workforce.

Moreover, outsourcing enhances flexibility in production. EMS providers can quickly adjust to varying production volumes, accommodating both small and large orders efficiently. This flexibility is crucial in meeting market demands without excess inventory or lead times. Ultimately, outsourcing to EMS providers can accelerate time-to-market and improve overall business agility.

Quality Control and Certifications in EMS

Quality control is a pivotal element in Electronic Manufacturing Services (EMS). Ensuring products meet rigorous standards is essential for customer satisfaction and brand reputation. EMS providers invest in state-of-the-art testing to maintain quality benchmarks.

Certifications play a vital role in the EMS landscape. They demonstrate a provider’s commitment to upholding industry and regulatory standards. Certifications such as ISO 9001, ISO 14001, and IPC standards are common among reputable EMS companies.

Key certifications and standards in EMS include:

- ISO 9001: Quality management systems.

- ISO 14001: Environmental management.

- IPC Standards: Electronics industry standards.

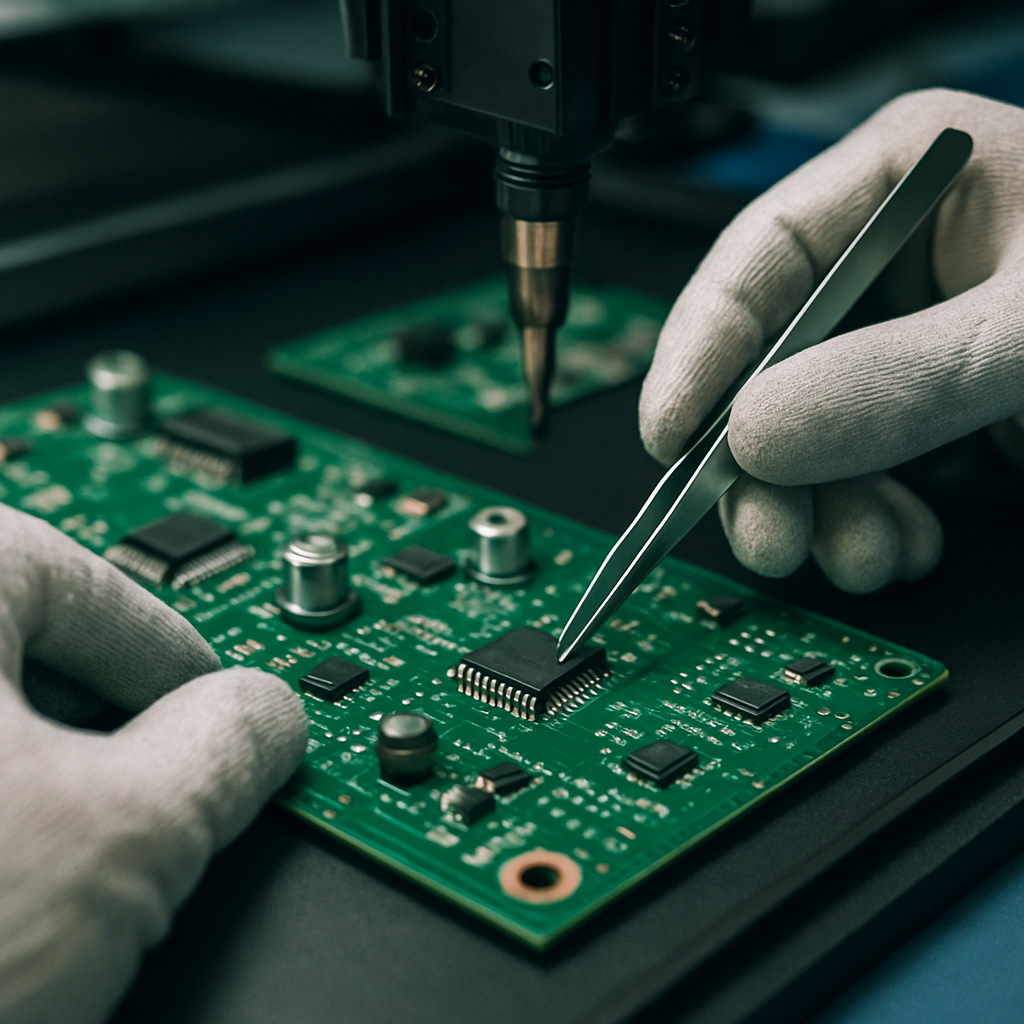

Photo by Ludovico Ceroseis on Unsplash

These certifications ensure consistent product quality and operational excellence. Additionally, robust quality control processes mitigate risks, enhancing the reliability and performance of products. By adhering to these standards, EMS providers instill confidence in their clients through quality assurance and continuous improvement.

Industries Served by EMS Companies

Electronic Manufacturing Services (EMS) providers cater to a diverse range of industries. They support sectors where technology and precision are crucial. With their expertise, EMS companies adapt to the specific needs of different markets.

The consumer electronics industry is a major client of EMS providers, as is the automotive sector. EMS also plays a significant role in medical device manufacturing, ensuring that devices meet stringent health standards. Aerospace and defense industries rely on EMS for their complex and high-reliability requirements.

Industries served by EMS include:

- Consumer Electronics

- Automotive

- Medical Devices

- Aerospace and Defense

Besides these, EMS companies are increasingly involved in emerging fields. They support sectors such as renewable energy and IoT, where innovative electronics solutions are crucial. By doing so, EMS providers are not only meeting current market demands but are also shaping the future of technology across multiple industries.

How to Select the Right EMS Partner

Choosing the right Electronic Manufacturing Services (EMS) partner is essential for success. The right partner can streamline your production process and reduce costs.

Begin by evaluating the EMS provider’s expertise. Make sure they have experience in your industry. This includes understanding the specific requirements and standards your products must meet.

Another key factor is the provider’s capacity for production. Check if they can handle your production volume efficiently. Scalability is vital, especially if you anticipate growth.

Consider the following criteria when selecting an EMS partner:

- Industry expertise and experience

- Production capacity and scalability

- Quality control systems

- Location and logistics capabilities

Furthermore, assess their quality control systems. High standards in testing and validation reduce defects and enhance reliability. Finally, consider logistics capabilities and their ability to ensure timely delivery. Selecting the right EMS partner involves thorough research and careful consideration.

Trends and Innovations in Electronic Manufacturing Services

The electronic manufacturing services (EMS) industry is undergoing rapid evolution. Advances in technology are leading to new trends and innovations.

Automation is at the forefront. EMS providers are increasingly using robotics and artificial intelligence (AI) to boost efficiency. These technologies reduce errors and lower production costs.

The integration of the Internet of Things (IoT) is also a game-changer. IoT enables real-time monitoring and control of manufacturing processes. This leads to improved quality and faster response times.

Key trends and innovations include:

- Adoption of AI and machine learning

- IoT integration for smart manufacturing

- Expansion of eco-friendly practices

- Use of advanced materials and techniques

Moreover, there is a growing emphasis on sustainability. EMS companies are adopting eco-friendly practices to meet regulatory and consumer demands. This includes reducing waste and using renewable energy.

These innovations are reshaping the EMS landscape. They promise more efficient, responsible, and high-quality production processes.

Challenges and Risk Management in EMS

Electronic manufacturing services face several challenges that require robust risk management strategies. Supply chain disruptions can pose significant risks. This includes material shortages and transportation delays.

Ensuring compliance with regional and international regulations is another key challenge. EMS providers must navigate complex legal landscapes to avoid penalties.

Mitigating risks involves strategic planning and proactive measures. Key risk management strategies include:

- Diversifying supplier networks

- Implementing quality assurance protocols

- Continuously monitoring regulatory changes

Technology also plays a role in managing risks. Advanced data analytics and real-time tracking systems help identify and address potential issues before they escalate, ensuring smoother operations.

The Future of Electronic Manufacturing Services

The future of electronic manufacturing services is bright and full of technological advancements. Innovations like artificial intelligence and machine learning are revolutionizing the industry. These technologies promise to enhance production efficiency and reduce costs.

Sustainability will play a pivotal role in shaping future EMS strategies. Companies are increasingly focusing on eco-friendly practices. This includes reducing waste and conserving energy during manufacturing processes.

The integration of smart technologies is set to transform EMS operations. The adoption of IoT and smart devices will streamline processes. This will result in improved quality and faster product delivery.

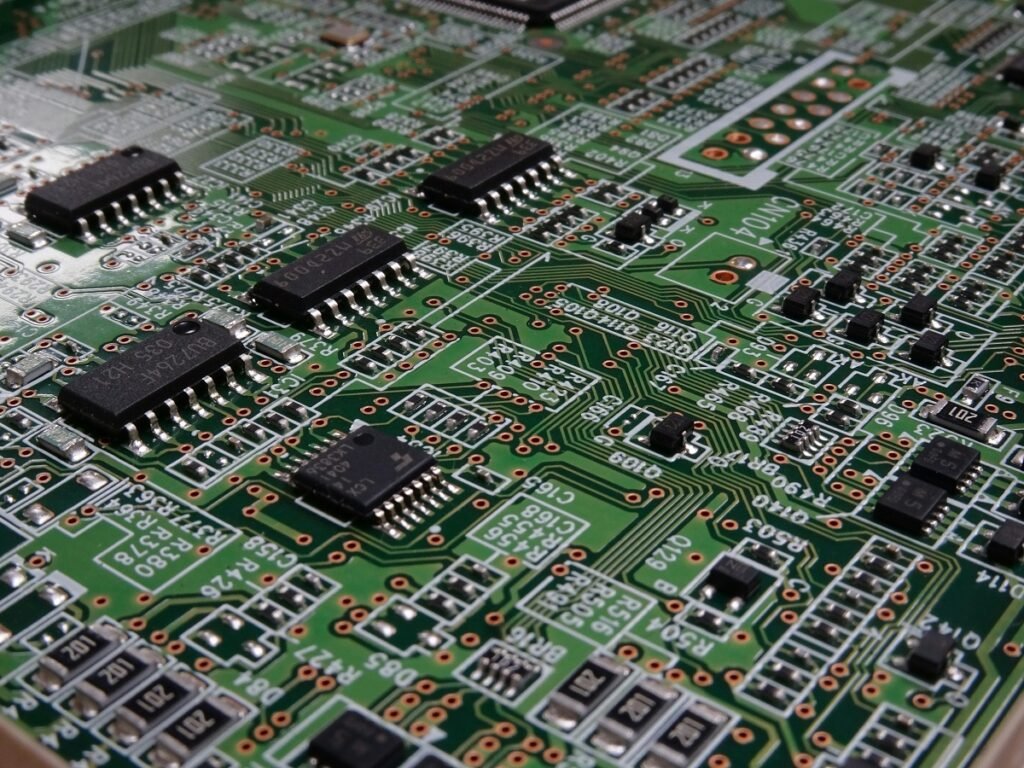

Photo by Simon Kadula on Unsplash