What is silicone sealant?

Silicone sealant is an elastic polymer rubber material formed after sulfurization using polydimethylsiloxane as the main raw material, supplemented with cross-linking agents, fillers, plasticizers, coupling agents, catalysts, and other paste-like substances. As a commonly used multifunctional polymer adhesive, silicone sealant can bond various substrates such as metals, organic plastics, glass, ceramics, and so on. It can be used to seal, fix, and bond circuit board components in electronic appliances. It can also play an important protective role in integrated circuit electronic circuit boards.

Benefits of silicone sealant

Simple and flexible operation:

The cost of the adhesive equipment is low, efficient, and fast. For example, single-component silicone sealant can be precisely applied, suitable for bonding small internal components of electronic and electrical equipment.

Excellent electrical insulation:

Silicone sealant has good electrical insulation in the range of -60℃ to 200℃. Frequency and temperature changes have minimal effects on the dielectric constant and dielectric loss factor, effectively improving the safety and stability of electronic and electrical operation.

High flexibility functions:

By adding functional fillers to the silicone sealant material, specific functions can be achieved. For example, silicone sealant with thermal conductivity can quickly dissipate heat to protect electronic components. Other functional silicone sealants, such as conductive silicone sealant, flame-retardant silicone sealant, and ultra-high-temperature-resistant silicone sealant, etc.

Excellent light resistance:

This makes it have special applications in electronic and electrical equipment, such as solar cell modules using photovoltaic silicone sealant.

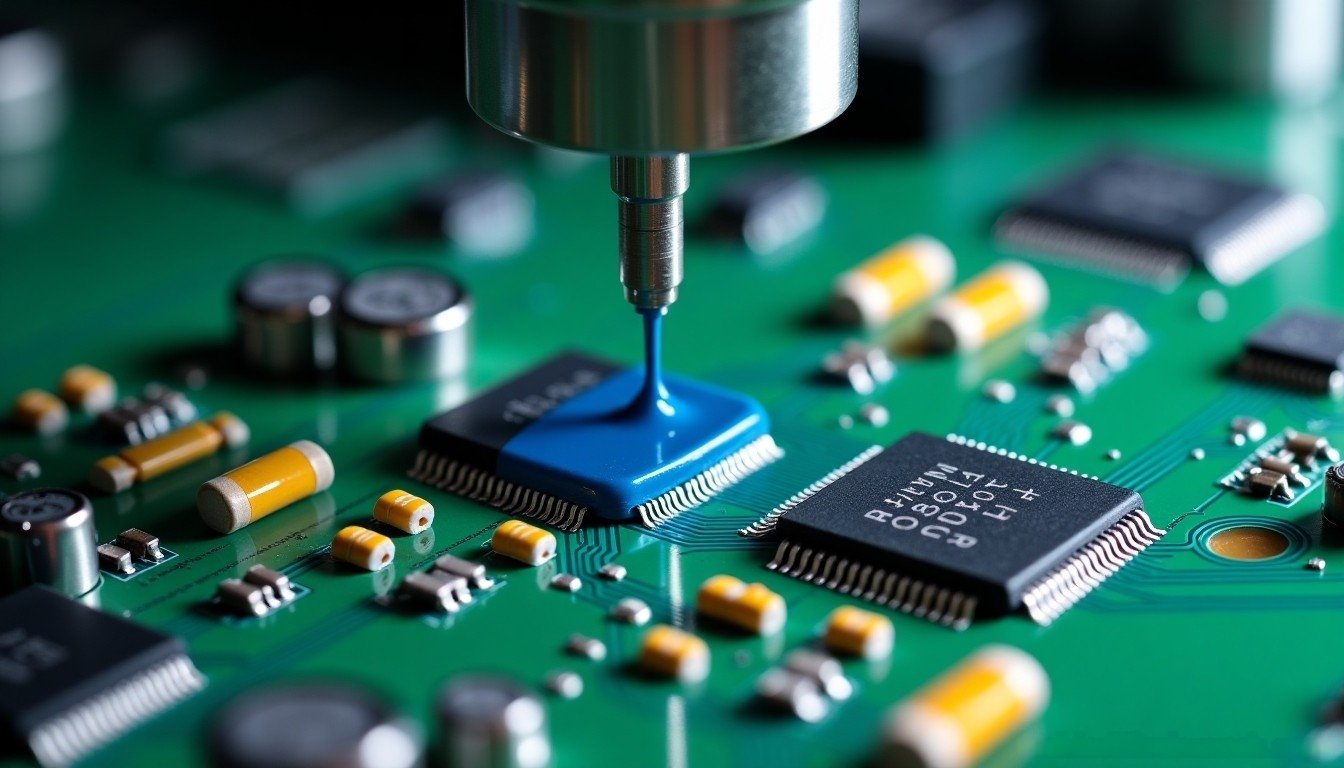

How to use silicone sealant to protect circuit boards?

Organic silicon sealant is an effective method to protect printed circuit boards (PCBs) from moisture, dust, and other environmental factors. Here are some steps to use silicone sealant to protect PCBs:

Clean the PCB

Before applying silicone sealant, make sure the PCB is clean and free of any dirt, dust, or debris. Use a soft cloth or brush to remove any particles that may be on the board.

Cover any areas that should not be covered

If there are any components on the PCB that should not be covered by silicone sealant, use masking tape to cover them. This will ensure that silicone sealant does not enter these areas.

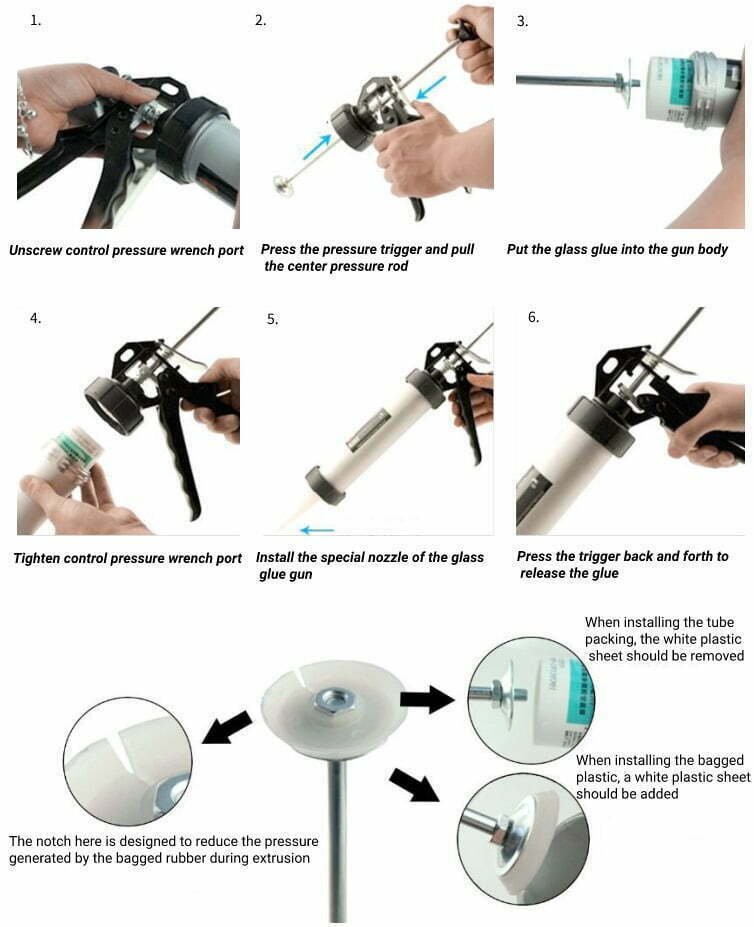

Apply silicone sealant

There are two ways to apply silicone sealant to your circuit board. One is to use a small brush or applicator to apply silicone sealant to the PCB, and the other is to use a silicone gun specially designed for silicone sealant. The following illustration shows the steps to use the silicone gun:

Be sure to apply a thin and even layer of silicone sealant, ensuring that it covers the entire surface of the circuit board.

Let the silicone sealant dry

After applying the silicone sealant, let it dry completely. The drying time can vary depending on the type of silicone sealant used, so be sure to follow the manufacturer’s instructions. Moreover, the drying time of silicone sealants would also increases with the thickness of the appliying on the PCB.

Inspect the PCB

Once the silicone sealant has dried, inspect the PCB to make sure that it is fully protected. Check for any areas where the silicone sealant may have missed and apply more as needed.

Note:

Silicone sealant releases irritating gas during the curing process, which can be harmful to eyes and respiratory system. Therefore, please use it in a well-ventilated environment or wear a mask while using it.

How to remove silicone sealant?

You may ask, “Can I remove silicone sealant if I have applied it in the wrong place?” Yes, you can. Before the silicone sealant cures, you can wipe it off with a cloth or tissue. Once it has cured, you need to scrape it off with a scraper or clean it with solvents such as xylene or acetone.

Application of silicone sealant

Household appliances:

Silicone sealant can be used for fixing components, filling radiators, bonding glass panels and partitions, fixing storage boxes, sealing frames, etc., in refrigerators, air conditioners, washing machines, and other household appliances.

Solar cells:

Photovoltaic systems are exposed to harsh weather conditions such as sunshine and rain during use. Silicone sealant can be used to protect photovoltaic cell components, such as the gaps between the frames, power junction boxes, and photovoltaic glass, to extend their service life.