There are many different PCB colors being used by manufacturers. Some of the most common include blue PCBs and green PCBs. So which pcb color is better for your project? Which is more widely used?

Although both types of printed circuit boards have very similar properties, there are some key differences that might help you decide which one would be best for your particular project. Keep reading to find out more about these options, their pros, cons, and other details you’ll want to know before deciding which one is right for you.

What is PCB Color?

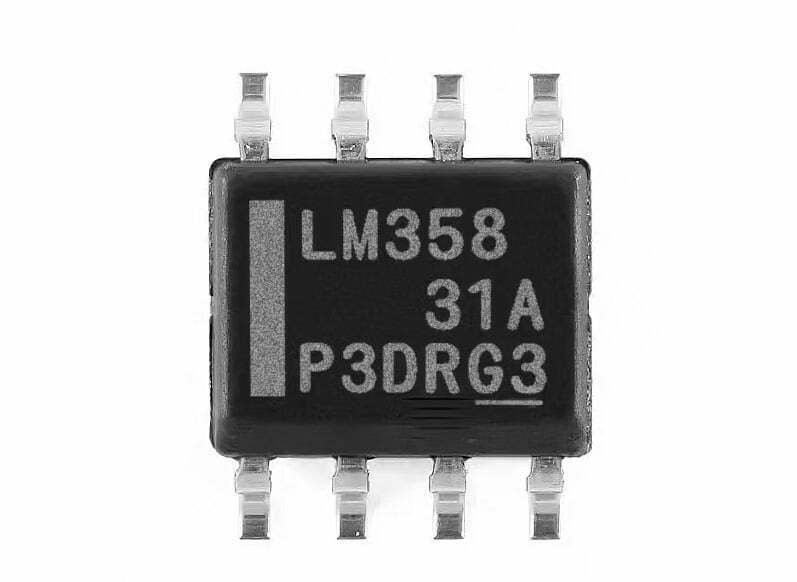

The surface colour that we see on the PCB is the colour of the solder mask or solder oil. A solder mask is a thin layer of insulating material that is applied to the surface of a printed circuit board (PCB) to protect the exposed copper circuitry from oxidation and to prevent accidental soldering to the wrong pads or pins. Soldermask comes in a variety of colours, including green, blue, black, yellow, red, and more. Green solder mask is the most common.

Types of PCB Colors

Blue PCB

Blue PCBs are also sometimes referred to as the blue board. These types of printed circuit boards are typically manufactured with a copper-clad core, which is a thin layer of copper that is commonly found inside printed circuit boards.

Blue PCBs are great for applications where higher strength is needed, such as controlling heavy machinery. Because they have a thicker and denser layer of copper, they can handle much more physical stress than other types of printed circuit boards. And they’re great for applications where a large amount of current is needed. These boards operate at higher voltages, which allow a higher current to flow through them.

You can also find these boards with several different coatings, like a tin finish or a conformal coating. These coatings have different properties and might be ideal for your specific needs. These boards are typically a light blue color, but they can also come in a wide range of other colors. They can also be found in different thicknesses, ranging from 1/16” to 1/4”. Blue PCBs are best for high-power applications, heavy machinery, and when a higher level of physical strength is needed.

Green PCB

Green PCBs are also sometimes referred to as the green board. They are great for low-power applications, like simple electronics. They also work great for simple wiring applications and are typically easy to manufacture with a low cost. Green PCBs are typically a dark green color and are single-sided, which means that only one side of the printed circuit boards is covered in copper. These boards typically don’t handle high voltages and don’t handle much current, which is why they’re great for low-power applications. These boards are also typically very thin, ranging from .031” to .062”. Green PCBs are best for low-power applications, simple wiring, and when a low manufacturing cost is desired.

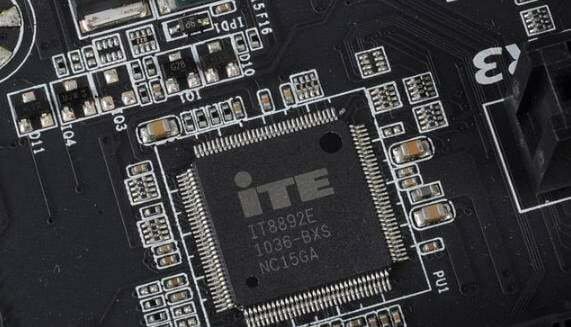

Black PCB

The copper black pcb boards are created with a higher percentage of carbon compared with their standard counterparts, which makes them better suited for high-frequency applications. Due to the fact that they are more conductive, they are often used to distribute power within electronic products. Black pcb boards often have higher resistance, making them less efficient than standard pcb boards; however, they have better voltage regulation, which makes them ideal for high-frequency applications. They are often used in power supplies, switched-mode power supplies (SWPS), high-voltage applications, and power-supply rectifiers. Black pcb boards can also be used in high-current applications, such as heaters, electric heaters, and other applications that require a high amount of current.

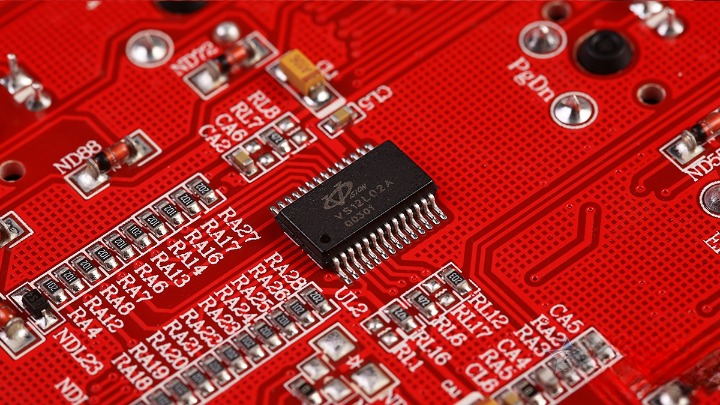

Red PCB

A red color pcb board can be used for a variety of applications, including making electrical connections or for mounting and securing components. Red is a popular color for pcb boards because it is easy to see and stands out from other colors. When choosing a red color pcb board, it is important to consider the size, shape, and thickness of the board, as well as the number of layers.

Why most of circuit boards are green?

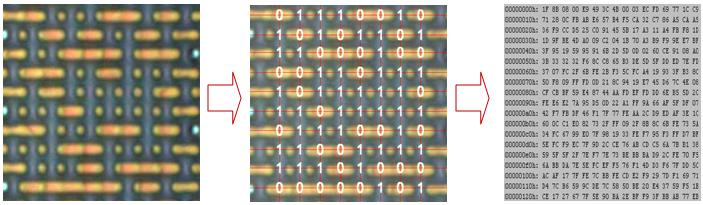

- Easier identification of component locations

The color green was chosen because it has the lowest absorption of light in the visible spectrum. This means that more light is reflected back to the operator’s eyes, making it easier to see the individual components.

- Higher solder mask quality

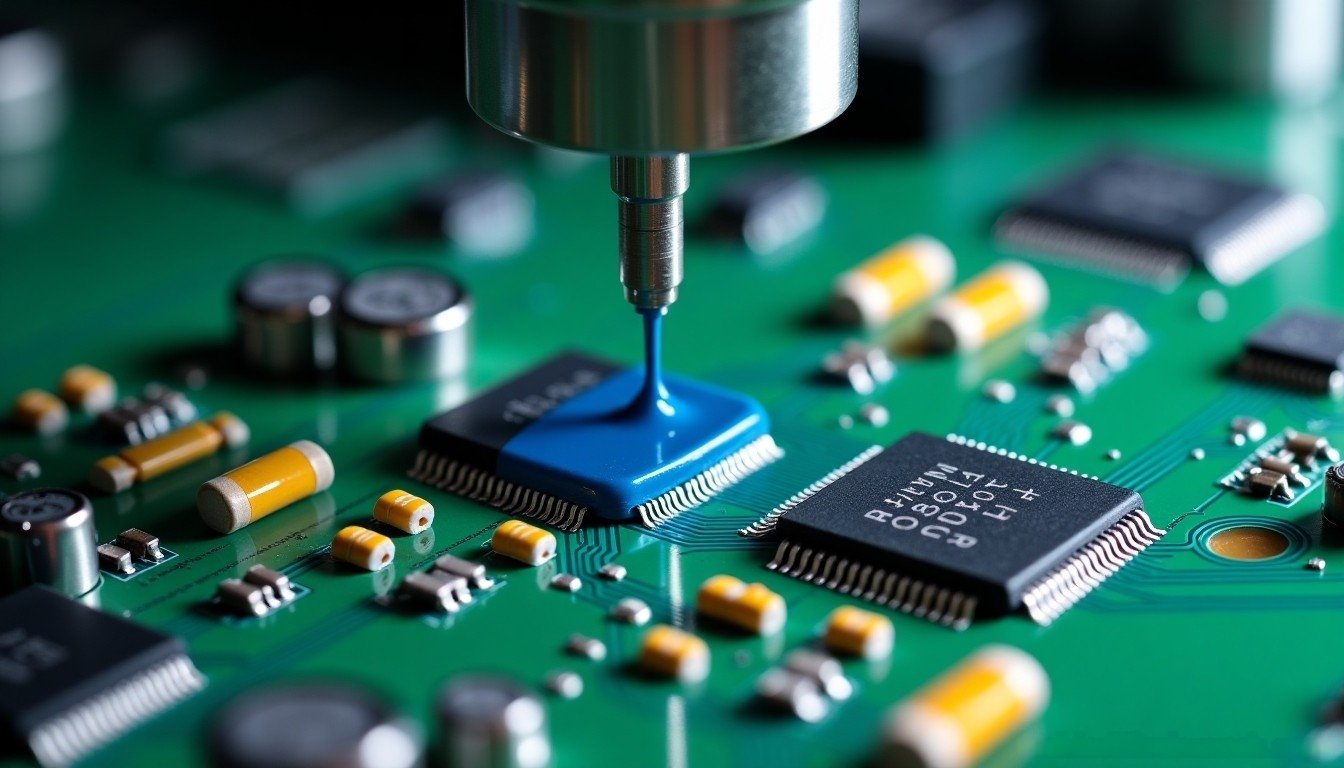

Green soldermask is less viscous than other colors. On high-density PCBs, the distance between the pads is small, and the width of the solder mask is smaller. When silkscreen soldermask is used, less viscous soldermasks are easier to print onto the PCB.

- Improve SMT efficiency

When SMT welding, it has to go through tinning, patching and final AOI verification. These processes all need to be calibrated by optical positioning. The green background color is better for the recognition effect of the instrument.

- Reduce visual fatigue

Due to process problems, the inspection of many pcb lines still relies on human eyes to complete. Green is a calming color that can help reduce stress and anxiety, which is important when working with delicate electronics.

- Cheaper Price

It is simple to get custom colours in solder mask with mass production; therefore, it is substantially cheaper. Because of this, green PCBs are frequently coloured green because of their cheap solder mask prices.

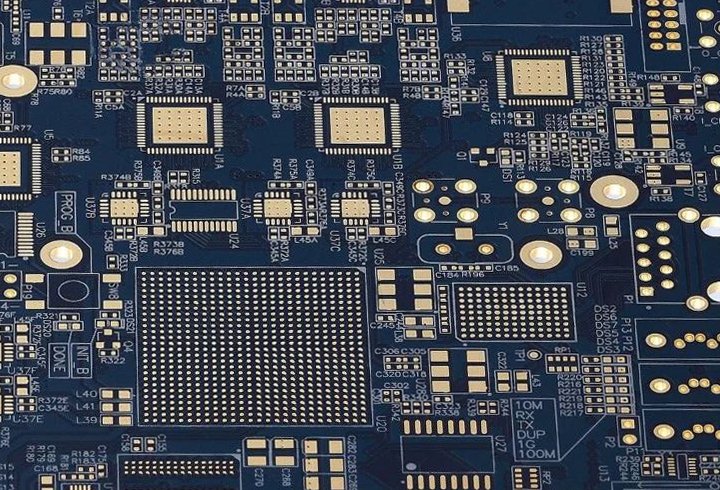

PCB Blue vs Green

About blue and green pcbs, some key differences might help you decide which one would be best for your particular project. These include:

– Physical strength – First, blue PCBs are typically stronger than green PCBs, which is helpful if the board needs to withstand a lot of physical stress or if it needs to withstand a lot of heat.

– Current capacity – Second, blue PCBs typically have a higher current capacity than green PCBs. This means that they can handle more current, which is helpful if your circuit requires a large amount of power.

– Copper thickness – Third, blue PCBs typically have a thicker layer of copper than green PCBs, which is helpful if you need a high amount of current or if you need to withstand a high amount of heat.

– Special coatings – Fourth, blue PCBs are sometimes available with a tin finish or a conformal coating. Green PCBs are not typically available with these special coatings.

Which is better for your project?

Ideally, you should use whichever printed circuit board is best for your specific project. No one PCB is better than the other, because each one has its strengths and weaknesses.

A green PCB is often the best option if you need a board that is simpler to manufacture. If you require a board with a high amount of power or physical toughness, a blue PCB would be better for your project. You can usually get helpful advice from the maker of printed circuit boards if you aren’t sure which one is optimal for your project.