What is Inkjet Printers?

Inkjet printers are a type of printer that uses tiny droplets of ink to produce images and text on paper or other materials. Inkjet printers are commonly used in homes and offices for printing documents, photos, and other graphics.

Types of Inkjet Printers

Inkjet printers work by spraying microscopic droplets of ink onto paper or other materials through a printhead. The printhead contains a series of nozzles that release the ink droplets onto the page. The size and location of the droplets are carefully controlled to produce sharp and detailed images and text.

How does a Inkjet Printer Work?

There are two types of inkjet printers: thermal inkjet and piezoelectric inkjet. Thermal inkjet printers heat the ink to create tiny bubbles that force the ink onto the page, while piezoelectric inkjet printers use electrically charged crystals to push the ink onto the page.

Piezoelectric Inkjet

Piezoelectric printing technology uses piezoelectric material as the main active element inside the print head. The material produces a phenomenon known as the piezoelectric effect, in which a (natural) substance generates an electric charge when it is subjected to an external force. Another effect, the inverse piezoelectric effect, also occurs when an electric charge acts on the substance, causing the substance to deform (move).

Piezo printheads feature PZT, a piezoelectric material that has been electrically polarized. All piezo printheads work in this same way, deforming the material in order to eject ink droplets. A printhead is an integral part of a printing system with nozzles that eject ink.

Piezo printheads consist of an active component called an actuator, with a series of lines and channels forming a so-called “fluid pathway”, and some electronics to control the individual channels.

The driver consists of parallel walls made of PZT material, forming channels. An electric current is applied to the ink channels, causing the channel walls to move. The movement of the walls of the ink channels creates acoustic pressure waves that force the ink to exit the nozzles at the end of each channel.

NICEJET A400-40Si Inkjet Printer

The NICEJET A400-40Si inkjet printer uses unique ink viscosity and liquid level detection technology for high print quality with more anti-migration and yellow inks than similar machines. It has a fully disassemblable nozzle design to solve the nozzle clogging problem and reduce operating costs. Furthermore, it’s designed with a magnetic non-contact high voltage switch to avoid machine failures caused by poor contact after long-term use.

Features

- 34-dot matrix design;

- Long-term stable operation;

- Supports data transmission;

- Simpler maintenance, easier detection;

- Individual the circuit and ink systems;

- Drawer-type ink system for easy maintenance;

- Equipped with automatic cleaning function;

- Built-in character libraries and online graphic editing;

- Customizable printing fonts and mode.

Capability:

- Nozzle aperture: 40 microns

- Print height: 0.6-10mm

- Number of lines to print: 1-5 lines

- Maximum number of printing dots: 34 dots

- Non-contact printing distance: 2-15mm

- The fastest printing speed: 340m/min

- Input system: Standard US keyboard

- Optional bitmap fonts: 5×5, 7×5, 9×7, 11×9, 16×11, 24×16, 32×24

Applications of Inkjet Printers

Daily Necessities Industry

Such as various packaging boxes, trademarks, labels, IC cards, membership cards, tickets, certificates, materials, etc.

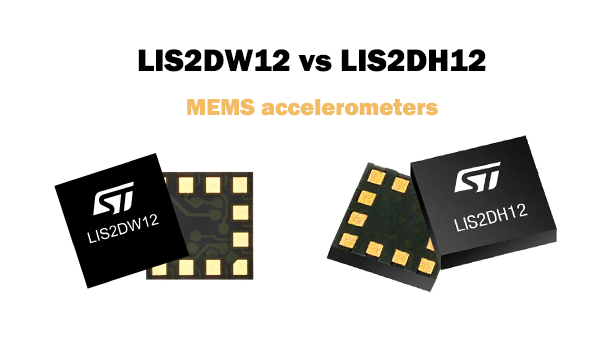

Electronic Industry

Various electronic components and various electronic products, semi-finished products such as batteries, LCD liquid crystals, PCB boards, radiators

Food Industry

All kinds of canned food, condiments, edible oil, and all kinds of biscuits and boxed food products, etc.

Beverage and Brewing Industry

Coding of various bottled and canned beverages, alcohol, pulp oil, vinegar and other products.

Building materials industry

All kinds of boards, including all kinds of MDF, blockboard, solid wood board, aluminum gusset board, asbestos board, wooden floor, etc.

Pipe profiles (extruded products): including PVC pipes, PVC trunking, PPR pipes, aluminum-plastic pipes, aluminum profiles, steel tube, aluminum coil, etc.

Medicine and health products industry

Production date, expiration date and batch number printing of medicines and health products.

Automobile Industry

Such as brake pads, clutch plates and other accessories.

Reverse Development of Inkjet Printers

Our expert team supports every step of your inkjet project development: IC decrytion, PCB to schematics, PCB redesign and upgrade, prototyping fabrication, sample testing. Feel free to contact us, if you have a project.