- info@reversepcb.com

- Home

- Services

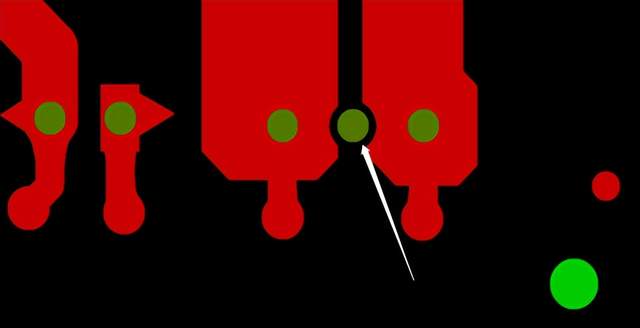

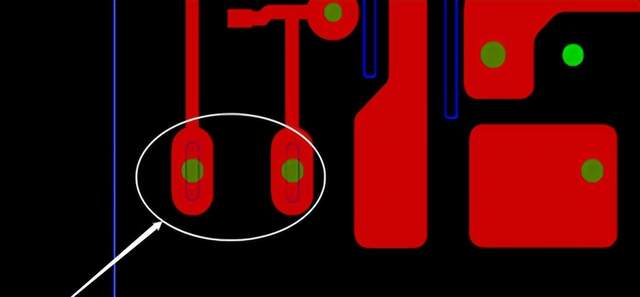

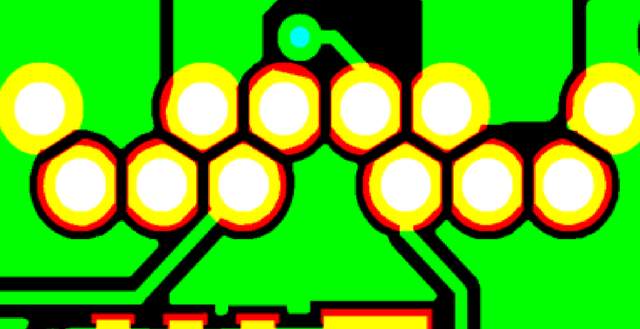

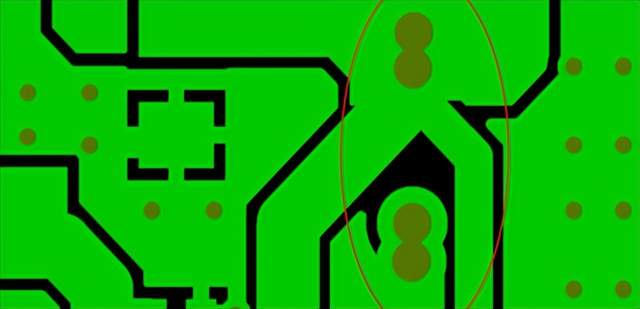

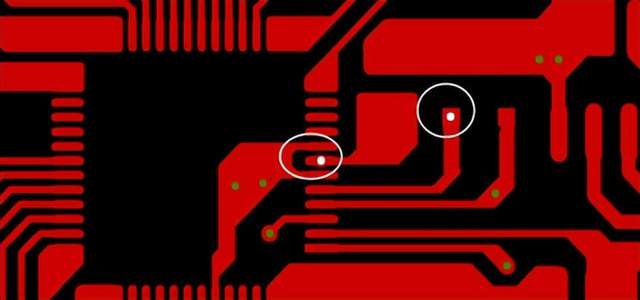

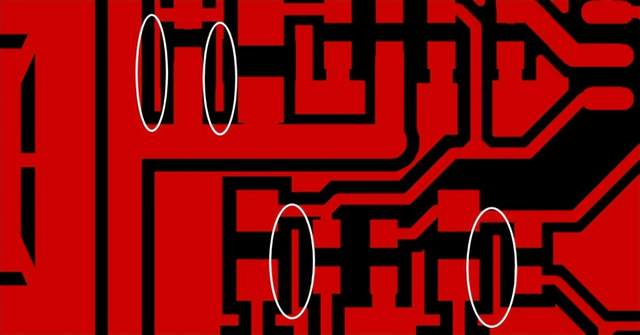

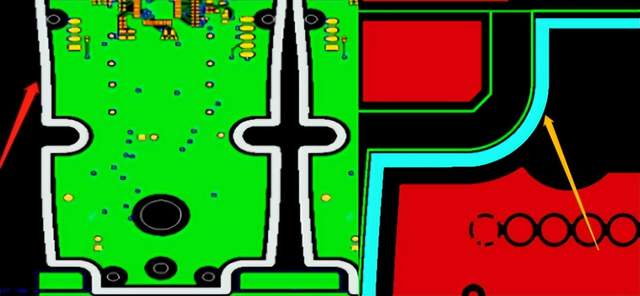

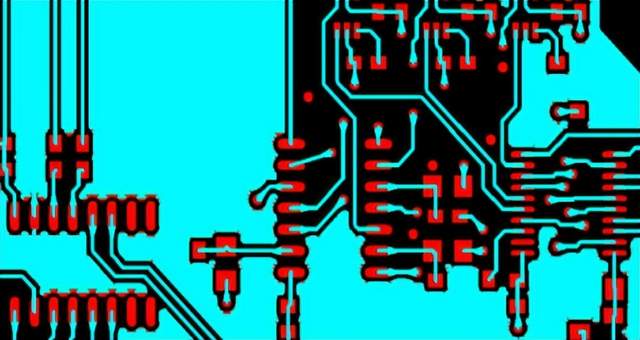

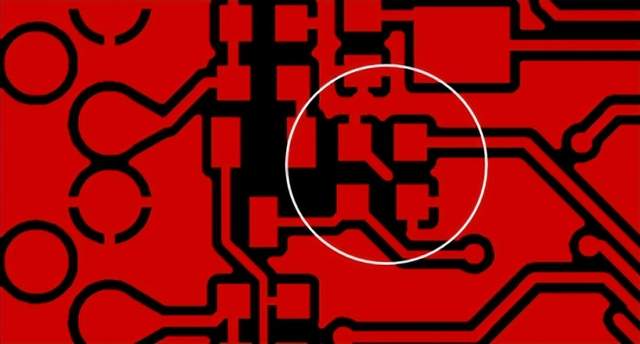

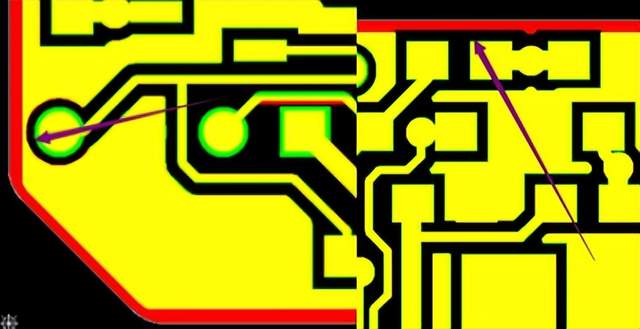

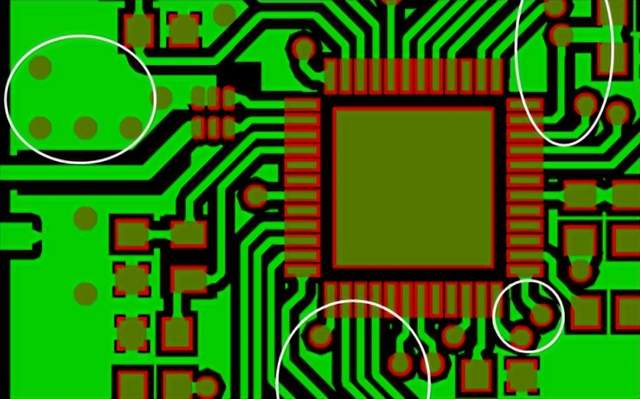

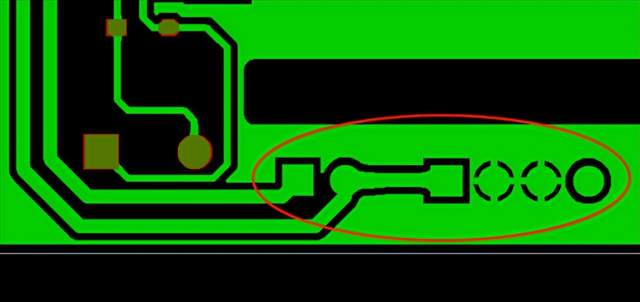

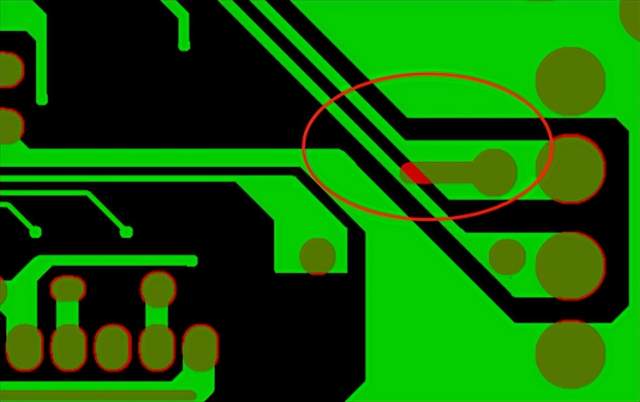

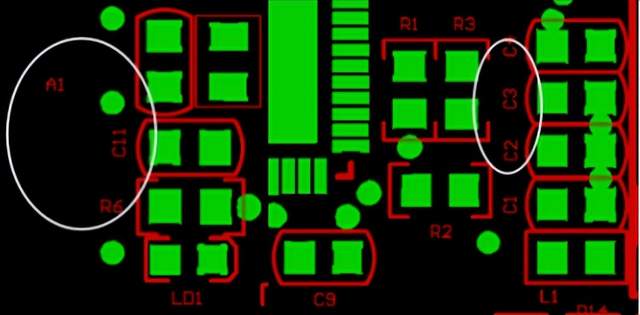

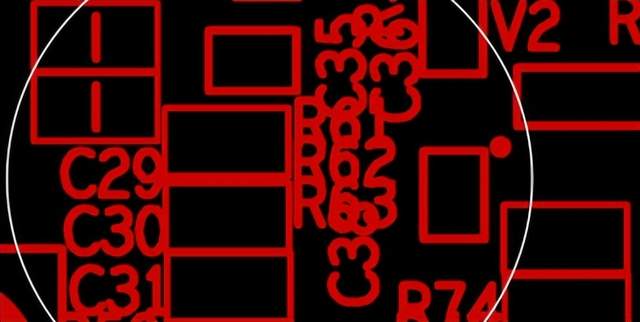

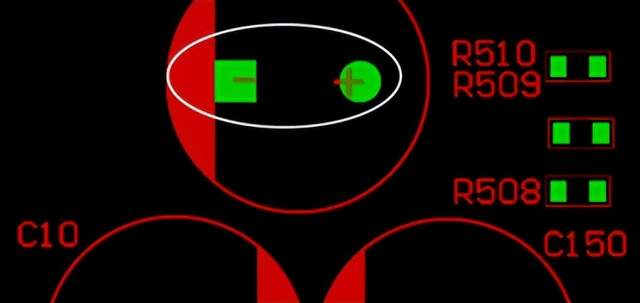

PCB Reverse Engineering

PCB Reverse EngineeringSchematic & Gerber restoration

IC Recovery / ExtractionMCU/CPLD code restore access & backup

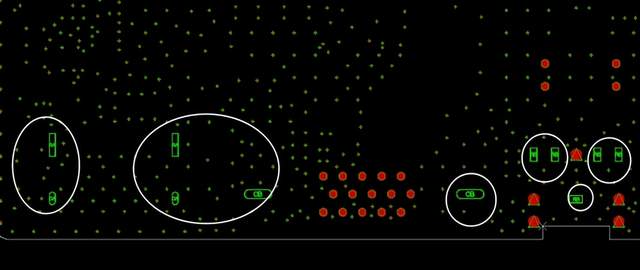

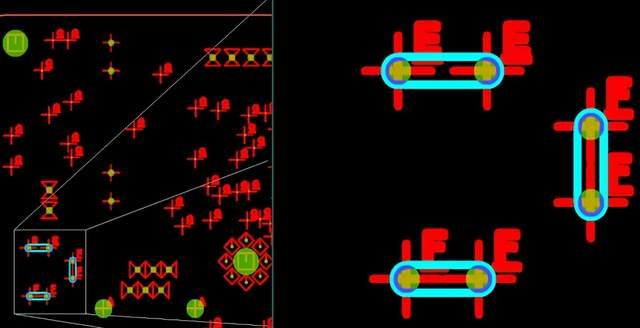

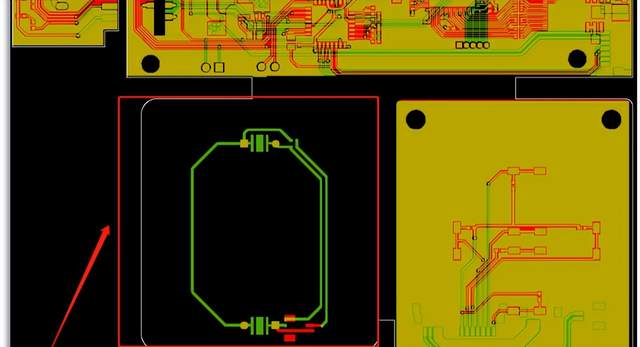

PCB Clone1:1 exact hardware replication

PCB Forward Engineering

Bluetooth DevelopmentBLE & Classic BT wireless solutions

Temperature ControlPrecision PID & thermal management

BLDC Motor DevelopmentHigh-efficiency motor drive control

Modbus DevelopmentIndustrial RS485/RTU communication

Microcontroller DesignCustom STM32/ESP32 firmware & HW

- ISO 9001 Certified Quality

- Global Shipping Support

- Case Studies

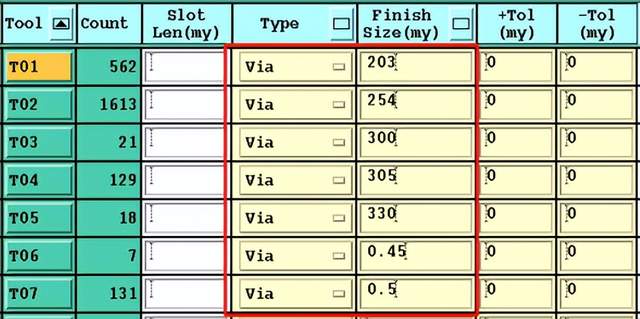

- PCB Tools

- Popular Tool

Calculate the PCB trace width based on temperature rise, current, and copper thickness (IPC-2152).

Explore All

- Knowledge Base

- Contact