Introduction to IC Packaging

Integrated Circuit (IC) packaging is a critical final step in semiconductor manufacturing. It’s the protective “armor” that safeguards a fragile IC chip from physical damage and environmental factors like moisture and dust. The package also provides the electrical connections, or leads, that allow the chip to connect to a printed circuit board (PCB) and communicate with other electronic components. As electronics have become smaller and more powerful, IC packaging has evolved to meet the demands for higher performance, greater density, and improved reliability.

Evolution of IC Packaging

IC packaging has gone through a remarkable evolution, driven by the need for smaller, faster, and more power-efficient devices.

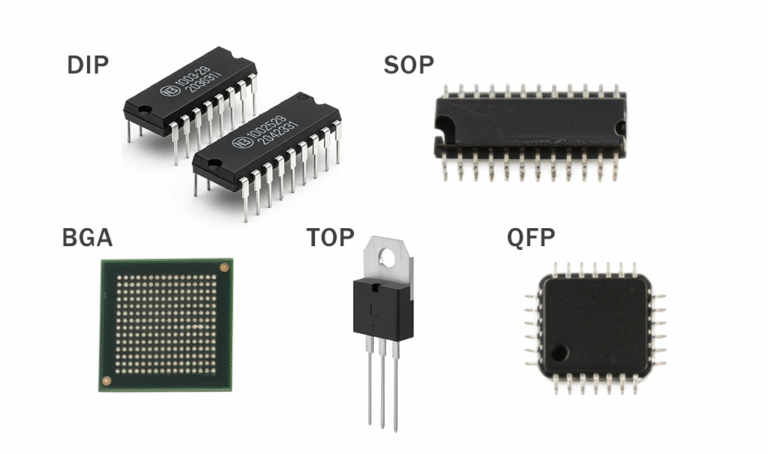

Through-Hole Technology: In the early days, the Dual In-line Package (DIP) was a standard. With its two rows of pins inserted through holes in the PCB, it was easy to use but took up a lot of space.

Surface-Mount Technology (SMT): The 1980s saw the rise of SMT. Components were soldered directly to the surface of the PCB, saving space and improving electrical performance. This led to packages like the Small Outline Package (SOP) and Quad Flat Package (QFP), which were much more compact than DIPs.

Array Packaging: The 1990s introduced the Ball Grid Array (BGA), which replaced pins with a grid of solder balls on the underside of the package. This allowed for a higher number of connections and better thermal management, making it ideal for powerful chips like CPUs and GPUs.

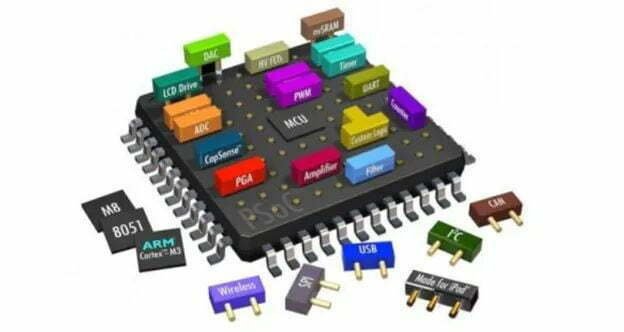

System Integration: The 21st century brought technologies like System-in-Package (SiP), which integrates multiple chips and components into a single package, and 3D packaging, where chips are stacked vertically to save space and improve communication speed.

Types of IC Packaging

IC packaging can be broadly categorized into three main types: through-hole, surface-mount, and array packaging. Here’s a table summarizing some of the most common types.

| Package Type | Description | Advantages | Common Applications |

|---|---|---|---|

| Through-Hole (e.g., DIP) | Rectangular body with two rows of pins inserted through the PCB. | Easy to prototype and repair; inexpensive. | Early computers, hobbyist projects, low-density circuits. |

| Surface-Mount (e.g., SOP, QFP) | Leads soldered directly to the surface of the PCB. SOP has leads on two sides; QFP has leads on all four. | Higher component density; better electrical performance; ideal for automated assembly. | Smartphones, digital cameras, consumer electronics, microcontrollers. |

| Array (e.g., BGA, CSP) | Grid of solder balls or pads on the underside of the package. Chip Scale Package (CSP) is a very small version of BGA. | High I/O count; superior electrical and thermal performance; very small footprint. | CPUs, GPUs, memory chips, high-end computing, smartphones, tablets. |

| System-Level (e.g., SiP) | Integrates multiple ICs and components into one single package. | Extremely compact; improved performance; higher functionality; faster product development. | Wearable devices, IoT sensors, 5G communication modules. |

In addition to those mentioned above, there are other important types of IC packaging, each serving a specific purpose:

Quad Flat No-Lead (QFN): This is a popular surface-mount package with no leads extending from the sides. Instead, it has a grid of metal pads on the bottom for electrical contact, making it extremely compact and well-suited for high-frequency applications.

Small Outline Transistor (SOT): As the name suggests, these are very small packages designed for individual transistors, diodes, and small-scale ICs. Their tiny size makes them ideal for applications with severe space constraints, like in mobile phones and smartwatches.

Plastic Leaded Chip Carrier (PLCC): An older surface-mount package, PLCCs have leads on all four sides that are bent inward in a “J” shape. They were often used for memory chips and microcontrollers and could be inserted into a socket.

Future Trends in IC Packaging

The future of IC packaging is focused on meeting the demands of next-generation technologies.

Continued Miniaturization and Integration: The drive for smaller devices will lead to even more compact packages and greater use of technologies like SiP, where multiple components are integrated into a single, cohesive unit.

High-Performance Packaging: The rise of AI and 5G requires packaging that can handle high-speed signals with minimal loss. This includes advanced 3D stacking with Through-Silicon Vias (TSVs) for faster communication between stacked chips and materials designed for high-frequency millimeter-wave applications.

Sustainability: The industry is increasingly focused on using eco-friendly, recyclable materials and reducing the overall environmental impact of packaging without sacrificing performance or protection.

Conclusion

The world of IC packaging is a cornerstone of modern electronics. From the early DIP that laid the groundwork for integrated circuits to the cutting-edge SiP and 3D stacking technologies of today, each packaging type has played a vital role in shaping the devices we use daily. The move from through-hole to surface-mount technology (SMT) enabled the miniaturization of electronics, while array packaging like BGA and CSP unlocked the potential for high-performance computing in ever-smaller footprints.

As technology continues to evolve, the future of IC packaging will be defined by even greater miniaturization, improved thermal management, and advanced system-level integration. These innovations are essential for powering the next wave of advancements in AI, 5G, and the Internet of Things. Ultimately, IC packaging is the unsung hero that ensures our electronics are not only powerful and efficient but also reliable and durable.