1. Develop and design cooperation methods:

Software design: MCU software development and design, according to customer requirements, write the required functional software; or rewrite the software part according to the customer’s actual hardware.

Schematic design: Design circuit schematics according to customer requirements.

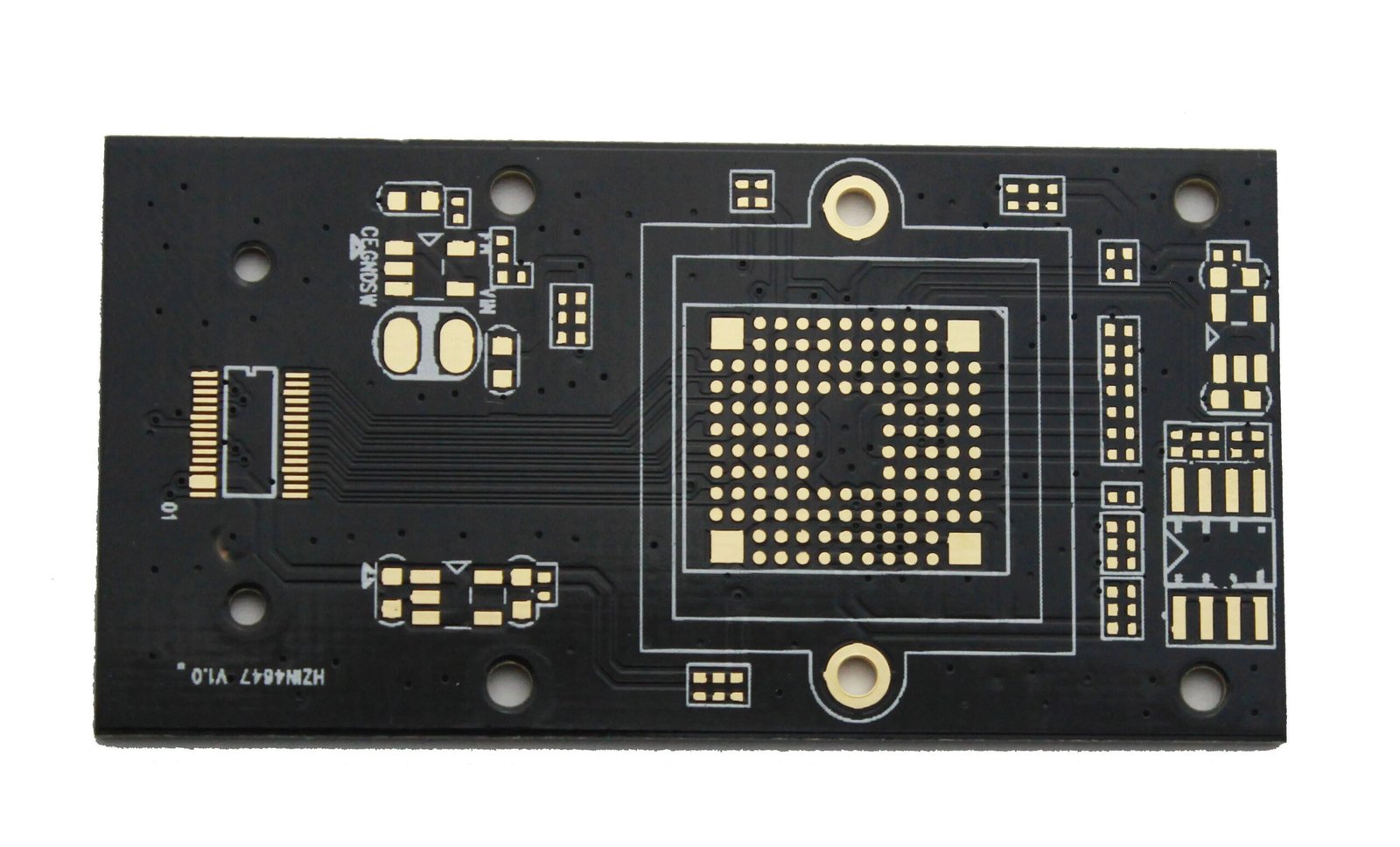

PCB design: PCB diagram can be designed according to customer schematic diagram, and PCB and bill of materials can also be manufatured according to customer template.

Production cooperation method: You can send the written program, schematic diagram, PCB data and bill of materials to the customer to let the customer burn the program and circuit board processing; you can also burn the program to the customer and help the customer to produce and process the circuit board.

2. Our advantages:

Software design: We can write low, medium and high-grade microcontroller programs to meet various needs of customers. Low-end single-chip microcomputers such as domestic Xinsheng and Bojuxing can achieve the lowest price in the market, but the cost performance is very high; mid-range ones use Taiwan Songhan and Youhua microcontrollers; high-end use PIC and STC microcontrollers, which can meet the needs of different customers.

Engineer team: The company has a team of first-class software and hardware electronic engineers, some of whom have more than ten years of research and development experience, and have designed switching power supplies of several kilowatts, which are among the most charming among the engineers in the corporate world. They solve many technical problems for customers, design high-competitive products, and create huge profits for many customers, which are fruitful.

equipment:

1) The company has advanced electronic processing equipment such as reflow soldering and medium and high-speed placement machines, and the production and processing of circuit boards have cost advantages;

2) The R&D department has advanced 100M digital oscilloscope, LED drive power input and output characteristic tester, variable frequency power supply, DC stabilized power supply, digital bridge, electronic load, withstand voltage insulation tester, grounding tester, oven and other complete electronic equipment Instruments and equipment lay the foundation for the development of reliable electronic products.

3. After-sales service commitment:

If there are any technical problems or cost-effectiveness problems in the products we develop, we will do our best to solve them no matter when customers raise them, before or after sales. And can come to provide technical support as needed. “Customers earn money, we earn money!” This is our product design requirement.

Strong R&D capabilities – professional and efficient, with a strong and complementary team, combined with years of experience in the design of various products in various industries, we can design targeted products according to the characteristics of the product industry, and ensure the feasibility, stability and cost of the solution. low.

Rich practical experience – a total of more than 80 categories and more than 500 products have been developed, involving small household appliances, electromechanical equipment, packaging machinery, medical equipment, fitness equipment, remote control locks, radio frequency induction, power modules, bioelectronics and other industries .

Let professional people do professional things – leave the problems of product development to us, you can rest assured to open up the market ahead!

If you have a good product, but suffer from insufficient R&D capabilities; if you have good distribution channels, but suffer from product design and development; if you want to focus on the market, rather than building a cumbersome R&D and production structure; then you You can hand over these problems to us, and you can go ahead to develop the market with confidence. We are your R&D department, your production workshop, your strong team, and your strong backing.

5. Scope of business:

Software development:

1) Lighting category:

Guardrail tube (one section, six sections), meteor light, point light source, remote control light, stage light controller, various LED control lights, LED flashlights, etc., ranger lights.

2) Home appliances:

Electric toothbrush, remote control curtain, electric fan controller, water dispenser, air purifier, water purifier, air conditioner, dehumidifier, heater, range hood, disinfection cabinet, electric water heater, rice cooker, coffee machine, soybean milk machine, hot water bottle , electric oven, electric iron, hair dryer, charger, electronic scale, lamp controller, induction control panel, infrared induction switch, etc.

3) Toys:

RF/IR remote control plane, RF/IR remote control car, PS machine, etc.

4) Communication class:

IC card reader/writer, access control system, wireless audio switching controller, TV remote control, air conditioner remote control, set-top box learning remote control, laser pen, RF/IR, satellite wireless switch, wireless control and cooperation with other ICs communication, etc.

5) Security category:

Car alarms, electric vehicle alarms, motorcycle alarms, odometers, smoke alarms, home fire-fighting smoke alarms, pyroelectric infrared alarms, etc.

6) Healthcare:

Acupuncture massager, foot bath, foot basin, vibration motor massager, fat throwing machine (belt), foot massager, waist massager, back hammering machine, treadmill, thermometer, slimming device, etc.

Hardware development:

1) Lighting categories: LED power supply, controller, LED thyristor dimmer/PWM/0-10V dimming/2.4G remote control dimming/infrared dimming, LED color changing temperature power supply, PIR pyroelectric body infrared induction / Sound and light control sensor controller and power supply, etc.

2) Industrial control boards: photoelectric switches, timers, ovens, remote control level detection circuits, telephone power supplies, small and medium power switching power supplies, counters, electronic scales, etc.

3) Mobile power supplies: automotive LEDs and controllers, ranger lights, voice controllers, vehicle power supplies, daytime running lights, LED headlights, charging treasures, and electric vehicle controllers.

4) Solar panels: various lighting and toys solar panels, solar chargers, solar converters.

5) Kitchen and bathroom appliances: wifi socket, air purifier, dryer, snow melting machine, touch mosquito repellent circuit, remote control curtain, electric fan controller, digital display water heater, egg cooker, water dispenser, air conditioner, dehumidification Machines, humidifiers, heaters, range hoods, disinfection cabinets, rice cookers, coffee machines, soy milk machines, electric ovens, chargers, etc.

6) Voice toys: induction water cup, recording and reporting toys, USB card speaker rocking chair, Bluetooth remote control car, etc.