Are you struggling with creating Gerber files for your PCB projects? The process of designing and producing printed circuit boards can be challenging, especially when it comes to getting the board size just right. In this article, I’ll be sharing some valuable tips to help you create Gerber files with the right board size.

Importance of Board Size in Gerber Files

The board size is an essential factor to consider when creating Gerber files. It determines the dimensions of the PCB, including its length, width, and thickness. The board size is crucial in ensuring that the PCB fits into the final product without any issues. The board size also dictates the manufacturing process and the overall cost of production.

How to Set the Board Size for Gerber Files in Altium Designer?

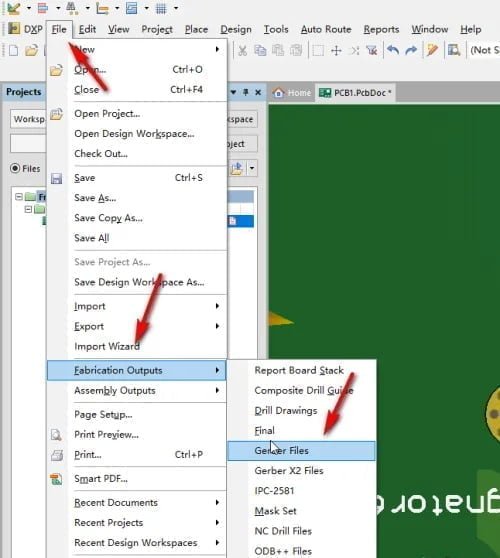

At first, let’s assume you have completed the board design. You can generate the Gerber files by selecting the “File” menu and clicking on “Fabrication Outputs” and then “Gerber Files”. This will open the “Gerber Setup” dialog box.

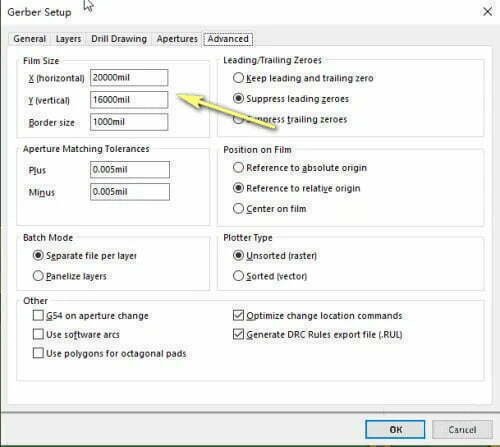

Under the “Advanced” tab, you can specify the board size. You can enter the width and height of the board, or the diameter if you have chosen a circular shape. You can also set the position of the board on the X and Y axes.

Once you have specified the Gerber output options, click on “OK” to generate the Gerber files.

How to Check the Board Size from Gerber Files?

To determine the board size from Gerber files, you can use a Gerber viewer or PCB design software that supports Gerber import. In the software, you can open the Gerber files and view the board outline or dimension layer, which shows the dimensions of the board.

Alternatively, you can open the Gerber files in a text editor and look for the dimensions in the file headers. The file names usually include the layer type and dimensions, such as “TopSilkLayer_4.2inX2.8in.gbr” for the top silk layer with a board size of 4.2 inches by 2.8 inches.

Factors to Consider When Choosing Board Size

Before choosing the PCB Board Size, there are several factors to consider to ensure that the PCB will fit into the final product correctly:

- The board size should be within the manufacturer’s capabilities.

- The board size should also be proportionate to the size of the final product.

- Your PCB should fit snugly into the final product without any protrusions or gaps.

- You should consider the thickness of the PCB and the distance between the components.

- The board size should also accommodate the necessary drill holes, vias, and mounting holes.

Gerber File Review and Verification

Before sending the Gerber files to the manufacturer, it’s essential to perform a thorough review and verification process. This can help identify any errors or issues with the Gerber files before they are sent to the manufacturer. The review and verification process should include the following steps:

- Check the board size and dimensions to ensure that they are correct.

- Check the Gerber files for any errors or missing information.

- Verify that the Gerber files contain all the necessary layers, including the copper layer, solder mask layer, and silkscreen layer.

- Verify that the drill holes, vias, and mounting holes are included in the Gerber files.

- Once the review and verification process is complete, the Gerber files can be sent to the manufacturer for production.