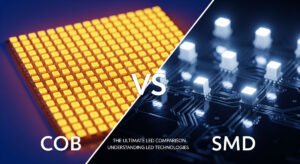

Understanding How COB LED Chips Redefine Performance

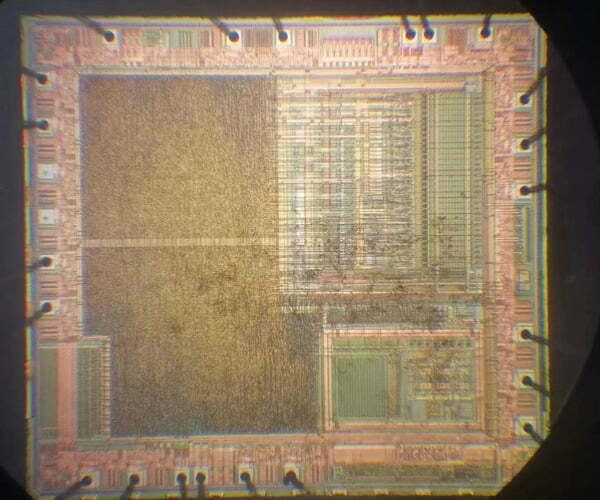

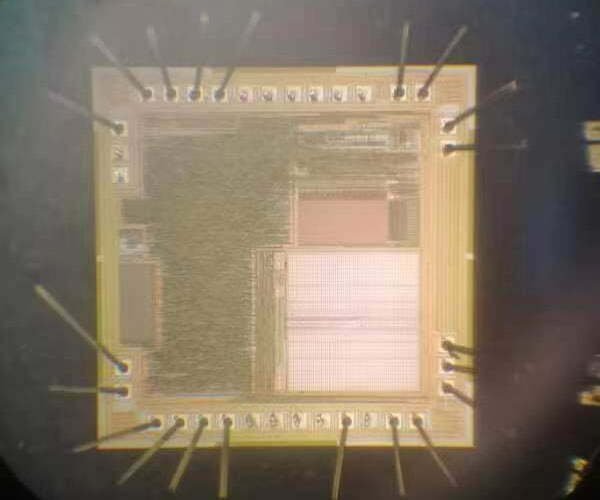

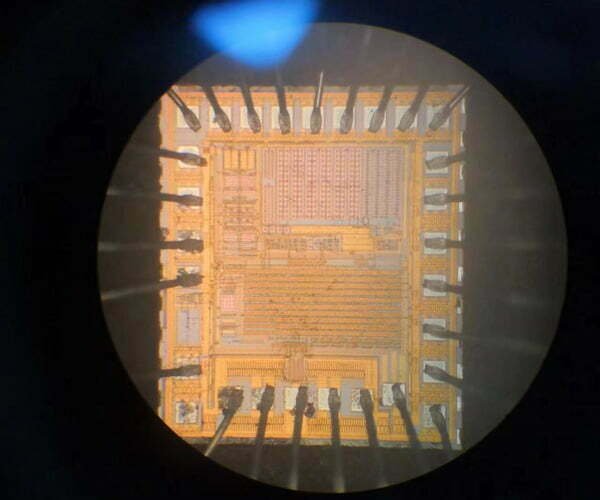

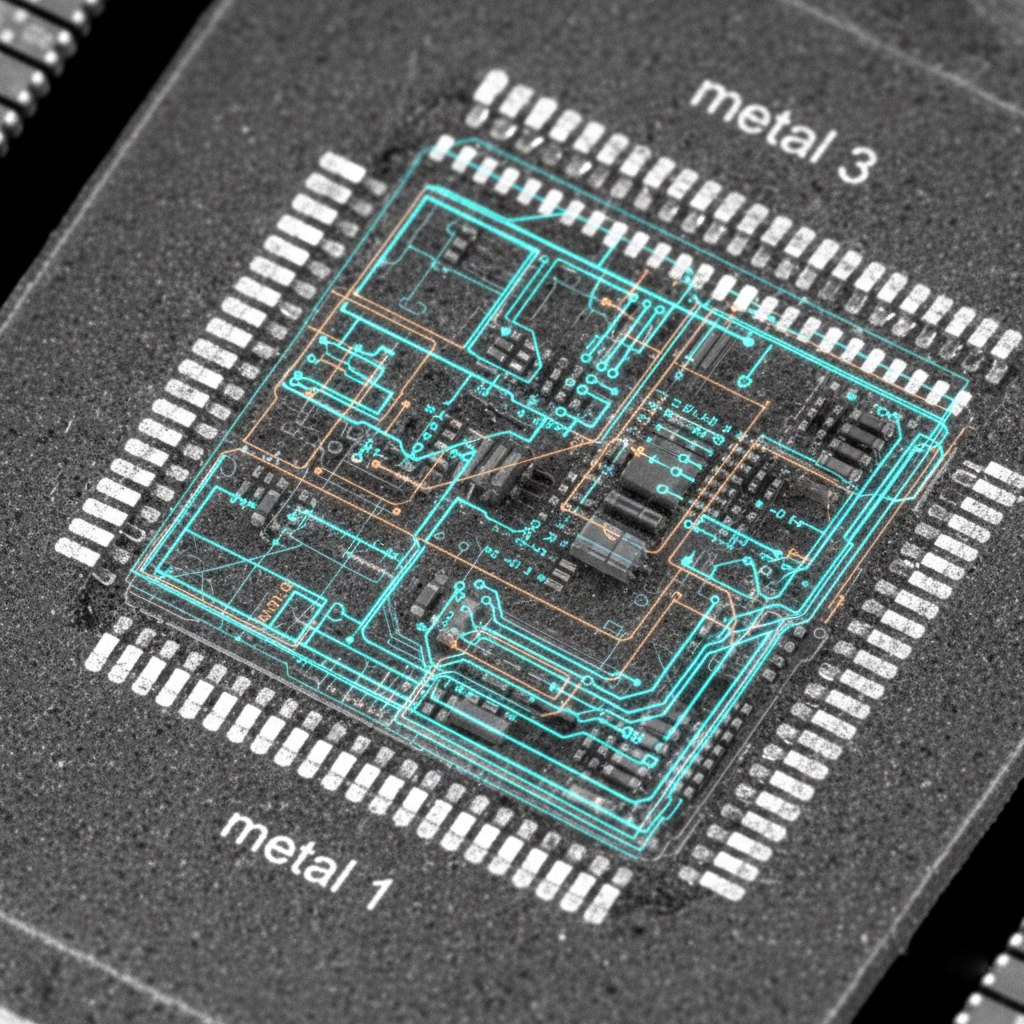

COB LED Deep Dive Introduction Architecture Performance Applications Comparison Redefining Lighting Performance Chip-on-Board (COB) technology marks a pivotal evolution in LED lighting. By integrating a