As technology continues to evolve, so too do the methods used to create and maintain the printed circuit boards (PCBs) that power our everyday devices. One of the most effective and efficient ways to clean PCBs is through the use of ultrasonic cleaning. In this blog, I’ll discuss what ultrasonic PCB cleaner is and the benefits it provides. I’ll also provide a guide to the ultrasonic cleaning process, the different materials used for cleaning, and the solutions available. Finally, I’ll provide some tips on choosing an ultrasonic cleaning machine and finding ultrasonic cleaning services.

What is Ultrasonic PCB Cleaner?

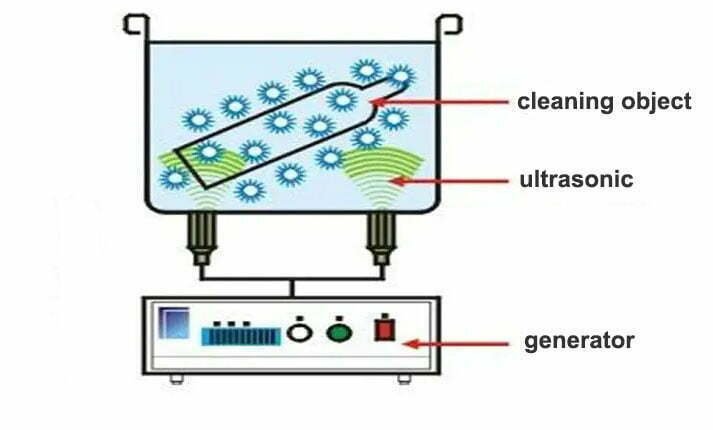

An ultrasonic PCB cleaner is a device that uses ultrasonic waves to clean printed circuit boards (PCBs). Ultrasonic cleaning works by producing millions of tiny bubbles that implode on the surface of the PCB, creating a powerful scrubbing action that loosens and removes dirt particles. The process is safe for most materials and can be used to clean a variety of components, including electronic circuits, pcb connectors, and solder joints.

Benefits of Ultrasonic Cleaning

Ultrasonic cleaning is an effective and efficient way to remove dirt, dust, and other contaminants from the surface of a PCB. The process is safe for most materials and can be used to clean a variety of components, including electronic circuits, connectors, and solder joints. Ultrasonic cleaning is faster and more effective than manual cleaning and requires fewer chemicals, making it more environmentally friendly. The process also minimizes the risk of damage to the PCB as the sound waves are gentle enough to avoid damaging delicate components.

In addition to its cleaning capabilities, ultrasonic cleaning can also help to extend the life of a PCB. By removing dirt, dust, and other contaminants, it helps to prevent corrosion and other damage that can occur over time. It also helps to prevent the buildup of static electricity, which can cause shorts and other electrical issues. Finally, ultrasonic cleaning can help to improve the performance of a PCB by removing any residue left behind by cleaning chemicals or other materials.

Ultrasonic PCB Cleaner Process

The ultrasonic cleaning process begins by suspending the PCB in an ultrasonic cleaning tank. The cleaning tank is filled with an ultrasonic cleaning solution, which is typically a mixture of water and a cleaning chemical. The cleaning tank is then filled with ultrasonic energy, which creates millions of tiny bubbles that rapidly expand and implode on the surface of the PCB. This implosion creates a powerful scrubbing action, which quickly and effectively removes dirt, dust, and other contaminants.

Once the cleaning process is complete, the PCB is removed from the tank and rinsed with water to remove any remaining cleaning solution. The PCB is then dried and inspected to ensure that all the contaminants have been removed. If necessary, the cleaning process can be repeated until the desired level of cleanliness is achieved.

Ultrasonic Cleaning Machine

Ultrasonic cleaning machines are designed to provide the highest level of performance and reliability. They are typically made from stainless steel and are equipped with a cleaning tank, an ultrasonic generator, and a timer. The cleaning tank is filled with the cleaning solution, and the ultrasonic generator is used to produce the ultrasonic energy needed to create the cleaning bubbles. The timer is used to control the cleaning process and ensure that the PCB is cleaned for the appropriate amount of time.

The ultrasonic generator is the most important component of an ultrasonic cleaning machine, as it is responsible for producing the ultrasonic energy needed for the cleaning process. The generator produces sound waves at a frequency of between 20 and 40 kHz, which creates millions of tiny bubbles that implode on the surface of the PCB. The generator is also equipped with a timer, which is used to control the cleaning process and ensure that the PCB is cleaned for the appropriate amount of time.

Materials Used For Ultrasonic Cleaning

Ultrasonic cleaning can be used to clean a variety of different materials, including metals, plastics, ceramics, and glass. The most commonly used materials for ultrasonic cleaning are stainless steel, aluminum, and brass. Each of these materials has its own advantages and disadvantages when it comes to ultrasonic cleaning.

Stainless steel is the most common material used for ultrasonic cleaning, as it is relatively durable and resistant to corrosion. It is also resistant to most cleaning solutions, making it ideal for a variety of different applications. Aluminum is another common material used for ultrasonic cleaning. It is lightweight and resistant to corrosion, but it is not as durable as stainless steel. Brass is the most durable of the three materials, but it is also the most expensive.

Ultrasonic Cleaning Solutions

The cleaning solution used in ultrasonic cleaning is typically a mixture of water and a cleaning chemical. The most common cleaning chemicals used are detergents, surfactants, and solvents. Detergents are used to remove dirt, dust, and other contaminants, while surfactants help to break down oils and grease. Solvents are used to dissolve stubborn deposits and help to remove them from the surface of the PCB.

The cleaning solution should be matched to the type of material being cleaned. For example, a cleaning solution designed for stainless steel may not be suitable for aluminum or brass. It is also important to use a cleaning solution that is compatible with the cleaning tank, as some cleaning solutions can corrode or damage the tank.

Ultrasonic Cleaning Tips

Ultrasonic cleaning is an effective and efficient way to clean PCBs, but there are a few things to keep in mind when using the process. First, it is important to ensure that the cleaning solution is compatible with the type of material being cleaned. Second, it is important to use the appropriate cleaning cycle for the material being cleaned. Finally, it is important to ensure that the cleaning tank is clean and free of any debris or contaminants before beginning the cleaning process.

It is also important to inspect the PCBs after the cleaning process is complete. This is to ensure that all the contaminants have been removed and that the PCB is free of any corrosion or damage. If any issues are found, the cleaning process should be repeated until the desired level of cleanliness is achieved.

How to Choose an Ultrasonic PCB Cleaner?

When choosing an ultrasonic cleaning machine, it is important to consider the size and type of PCBs that will be cleaned. The size of the cleaning tank will determine the size of the PCBs that can be cleaned, so it is important to choose a machine with a large enough tank to accommodate the size of the PCBs. It is also important to choose a machine with a powerful enough ultrasonic generator to create the necessary cleaning bubbles. Finally, it is important to make sure that the machine is equipped with a timer, as this will help to ensure that the PCBs are cleaned for the appropriate amount of time.

Ultrasonic Cleaning Services

In addition to buying an ultrasonic cleaning machine, it is also possible to outsource the cleaning process to an ultrasonic cleaning service. These services specialize in providing expert ultrasonic cleaning services and can help to ensure that the cleaning process is done correctly and efficiently. They also have access to a variety of different cleaning solutions, which allows them to tailor the cleaning process to the specific needs of the PCBs.

If you’re looking for an ultrasonic cleaning service, it is important to choose one that has experience in cleaning the type of PCBs you need to clean. It is also important to make sure that the service is reliable and trustworthy. Finally, it is important to make sure that the service is competitively priced and offers a guarantee of satisfaction.

Conclusion

Ultrasonic PCB cleaning is an effective and efficient way to clean a variety of different materials, including metals, plastics, ceramics, and glass. The process involves suspending the PCB in an ultrasonic cleaning tank and using ultrasonic energy to create millions of tiny bubbles that quickly and effectively remove dirt, dust, and other contaminants. The process is much faster and more effective than manual cleaning and requires fewer chemicals, making it more environmentally friendly.

When choosing an ultrasonic cleaning machine, it is important to consider the size and type of PCBs that will be cleaned. It is also important to make sure that the machine is equipped with a powerful enough ultrasonic generator and a timer to control the cleaning process. Finally, it is possible to outsource the cleaning process to an ultrasonic cleaning service, but it is important to choose one that is experienced in cleaning the type of PCBs you need to clean.

Ultrasonic PCB cleaning is an effective and efficient way to ensure that your PCBs are clean and free of dirt, dust, and other contaminants. With the right machine and the right cleaning process, you can ensure that your PCBs are always looking their best and performing at their highest level. So, if you’re looking for a reliable and effective way to keep your PCBs clean, ultrasonic cleaning may be the perfect solution.