What is Power Bank?

A power bank, also known as an outdoor portable charger, is a compact and portable device used to recharge electronic devices while on the go. It typically contains a rechargeable battery and a charging circuit, and can be charged up beforehand for use when a wall outlet is not available. Outdoor portable chargers come in a range of capacities, from small models that can recharge a single device to large models that can recharge multiple devices or even laptop computers. They are designed for outdoor activities, travel, and other situations where access to power is limited. With an outdoor portable charger, users can keep their devices charged and ready for use, even when they’re away from home or a conventional power source.

Why do reverse engineering on outdoor portable chargers?

Reverse engineering an outdoor portable charger has become increasingly popular in recent years due to several reasons:

Customization: By reverse engineering a portable charger, users can customize the device to better meet their specific needs and preferences. For example, they can increase the charging capacity or add new features to the device.

Cost savings: By reverse engineering a device and making their own modifications, users can save money compared to purchasing a similar device with the desired features already built-in.

Access to proprietary information: Reverse engineering can provide users with access to proprietary information about a device’s design and functionality, which they can use to improve their own products or create new products that are compatible with the original device.

The market of outdoor portable chargers

In terms of market outlook, the demand for outdoor portable chargers is expected to continue growing in the coming years, driven by the increasing use of mobile devices and the need for convenient and reliable charging solutions while on the go. As a result, the market for reverse engineered outdoor portable chargers is likely to grow as well, as users look for customized and cost-effective alternatives to commercial products.

However, it’s important to note that reverse engineering can have legal and ethical implications, and it may be subject to patent or copyright laws. As a result, it’s important to carefully consider the potential consequences before embarking on a reverse engineering project.

Parts of Outdoor Power Bank

The high-power outdoor mobile power supply usually consists of a shell, a battery core and a circuit board.

Shell part

The shell is mainly used to encapsulate the product, and realize the functions of beautiful appearance and protection. It is usually made of plastic and metal. Some popular products are often made of aluminum all-gold material.

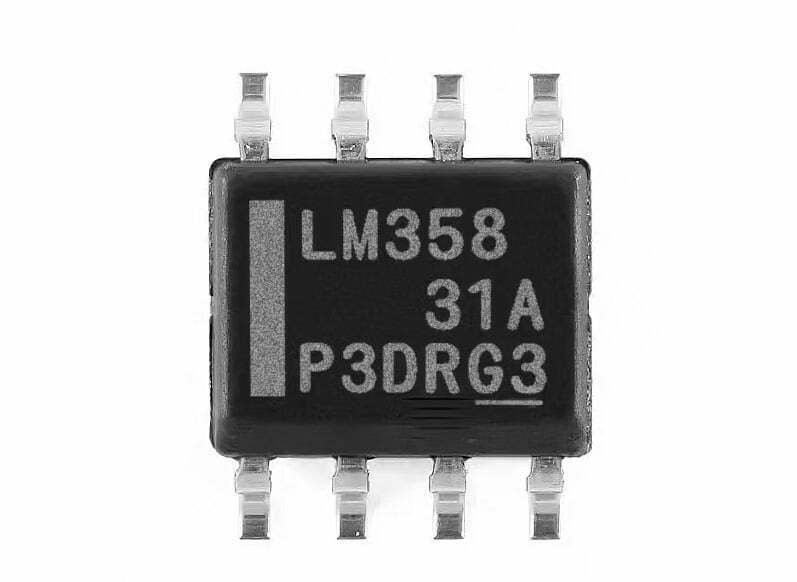

Cell and circuit part

The lithium core capacity indicator circuit is composed of some mature and stable voltage monitoring chips with the circuit.

Cell protection circuit

The cell protection circuit consists of three parts: overcharge protection, overdischarge protection, and overtemperature protection. Usually, a triple protection is constructed by some MOS voltage regulator cores and self-recovery fuses, which greatly enhances the safety of lithium cells.

Charge management circuit

The charging management circuit uses the battery charging management chip to divide the charging process into four parts: trickle charging, constant current charging, constant voltage charging and maintenance charging, so that the portable power supply can store energy to the greatest extent.

DC-DC boost circuit

The DC-DC boost circuit generally adopts the integrated chip of the DC conversion switch control type, which can release the capacity of the lithium core to the maximum extent within the safe range, and achieve the purpose of supplying power to a variety of digital devices.

Function expansion circuit

The function expansion can usually be updated and added according to user needs, such as the common emergency nighttime high-brightness, anti-theft security alarm, camping mosquito repellent and so on.

General Parameters of Outdoor Power Bank

Battery:

- Battery pack: usually 200WH-1200WH;

- Rated power: 200W-1200W;

- Battery Type: High Quality Lithium Ion Battery;

Input voltage (charging method):

- AC: AC 110V-220V 60/50Hz charging;

- DC: Adapter 22V/5A (110W charging;

- Input Conversion: 90%+;

Solar panel charging:

- 1 TPYE-C: 20V/3A 60WMAX (double-pass) charging;

- Multiple USB: 5V/2.41A;

- Multiple USB-QC3.0: 5V/3A, 9V/2A, 12V/1.5A 18W MAX;

- Multiple TPYE-C: 20V/3A ) (can be double-pass);

Output method:

- AC output: 220V 50Hz / 110V 60Hz/50hz (three US/Japanese gauges, two national standard outputs);

- Four DC outputs DC:13.2V/10A(MAX);

- Car charger output: 13.2V/5-10A MAX;

- Output conversion: more than 90%;

- lighting output;

Working temperature:

- Charging temperature: 0~40℃(32~104℉)

- Discharge temperature: -10~60℃ (14~140℉)

- Storage temperature: -20~45℃(-4~113℉)

Others:

- Lifetime: >1000 times

- Security protection: multiple protection

Reverse Engineering a Portable Charger

Portable chargers are becoming increasingly popular, due to the fact that they let you charge your devices on the go. However, many don’t realize that they can also be reverse engineered and used in a variety of creative ways.

Here we introduce the ways about how to reverse engineer a generic portable charger and use it for things like powering an Arduino board or other electronics.

Gather Materials

The first step is to gather the necessary materials. You will need a generic portable charger with a USB port, a soldering iron, solder, electrical wire, a multimeter, and some basic tools (screwdrivers, pliers, etc.). You may need other materials depending on the project you are working on.

Disassemble the Charger

Before you can start reverse engineering the charger, you will need to disassemble it. Start by unscrewing the four screws on the back of the charger. Then, use a small flathead screwdriver to pry apart the two halves of the charger. Be careful not to damage any of the internal components.

Identify the Circuit

Once you have opened up the charger, you should be able to identify the circuit board that controls the charging process. This is usually the largest component in the charger. It will be connected to the USB port, which is where the power is delivered to the device being charged.

Test the Circuit

Now it’s time to test the circuit. Use your multimeter to check for any shorts or other problems with the circuit. Make sure there are no leaks in the power cables that could cause a fire. If everything looks good, you can move on to the next step.

Wire up the Circuit

Once you have tested the circuit, you can begin wiring it up. First, connect the positive and negative terminals of the circuit board to the USB port. Then, connect the input power leads to the charger’s input power source. Again, double-check that everything is connected properly, as any mistakes could create a safety hazard.

Power Up the Project

The last step is to power up the project. Once the circuit has been wired up, simply connect the input power source to the USB port and the project should power up.