Surface-Mount Technology (SMT)

What is Surface-Mount Technology?

Surface-mount technology (SMT) is a electronic assembly process of mounting leadless or short lead surface mount components (SMC/SMD) on the surface of a printed circuit board (PCB) or on the surface of other substrates, and then soldering and assembling by reflow soldering or dip soldering.

Types of Surface-Mount Technology

our PCB design and debugging engineers will guarantee to make 100% accurate schematic diagrams and perfect prototypes for you.

Sort by size

There are 3 main types of surface-mount technology: small-outline package (SOP), surface-mount device (SMD) and ball grid array (BGA). The first two are smaller form factor components, while the last is larger. The size of your component will determine which type of surface mount technology it uses.

- small-outline package (SOP)

- surface-mount device (SMD)

- ball grid array (BGA)

Sort by process

Through-hole technology, and Soldering Techniques and Tape-out technology. Through-hole technology uses sockets and mating pins to mechanically attach components to circuit boards. Tape-out technology uses adhesive tapes instead of sockets to attach components to circuit boards.

- Through-hole technology

- Tape-out technology

- Soldering Techniques

surface mount technology applications

- Digital products: video cameras, digital cameras, speakers, MP3, mobile phones, voice recorders, scanners, set-top boxes, etc.

- Network equipment: circuit boards for network adapters, routers, switches, modems

- Office products: fax machines, printers, copiers, projectors, shredders, scanners, etc.

- Industrial instruments: control panels of machines such as lathes, milling machines, grinders, planers, etc.

Surface Mount Technology Pros and Cons

There are many benefits of surface mount technology, but the disadvantages are also obviously as below.

Pros

- Smaller size compared to traditional components

- More flexibility for PCB design

- Reduce material costs and shipping costs

- Efficiently automate production

- High frequency help reduce electromagnetic and radio frequency interference

Cons

- Difficult to inspect small components

- SMT is quite sensitive to foreign materials

- It is expensive to make SMT PCB

- SMT requires more time to install

- There is a risk of short-circuiting between components as they are close together

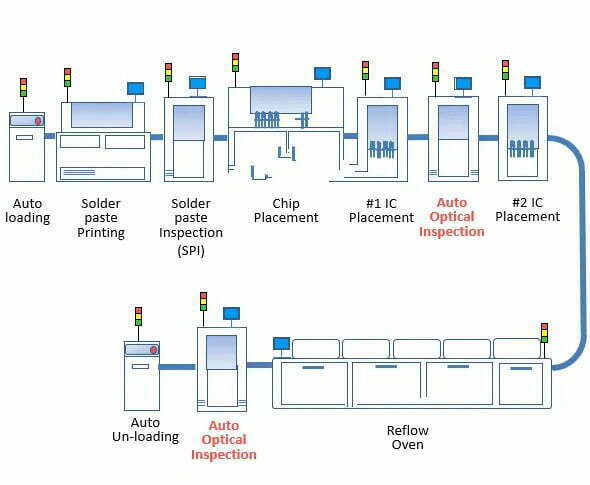

Surface Mount Technology Process Flow

Under normal circumstances, the electronic products we use are designed by pcb plus various capacitors, resistors and other electronic components according to the designed circuit diagram, so different electrical appliances require various smt processes to process. The following is our SMT process flow:

Solder Paste Printing (Jet Printing)

First, fix the template for the mold for printing solder paste (or directly program it on the solder paste inkjet printer), and then print the solder paste on the PCB.

SMC Placement

The PCB board that has completed solder paste printing passes through the automatic production line and enters the high-speed placement machine to start the regular placement of the packaged devices.

Mounting of core components (BGA, IC)

Select a high-precision placement machine to mount core devices such as (IC chips, various functional chips, BGA).

reflow soldering

Solder is melted by different heating methods such as reflow oven, infrared heating lamp or heat gun to bond SMT electronic components to printed circuit boards.

AOI Test

AOI inspection is adopted for PCB boards without obvious defects. The inspection equipment collects images of each solder joint on the PCB through a camera and compares it with the previously imported data.

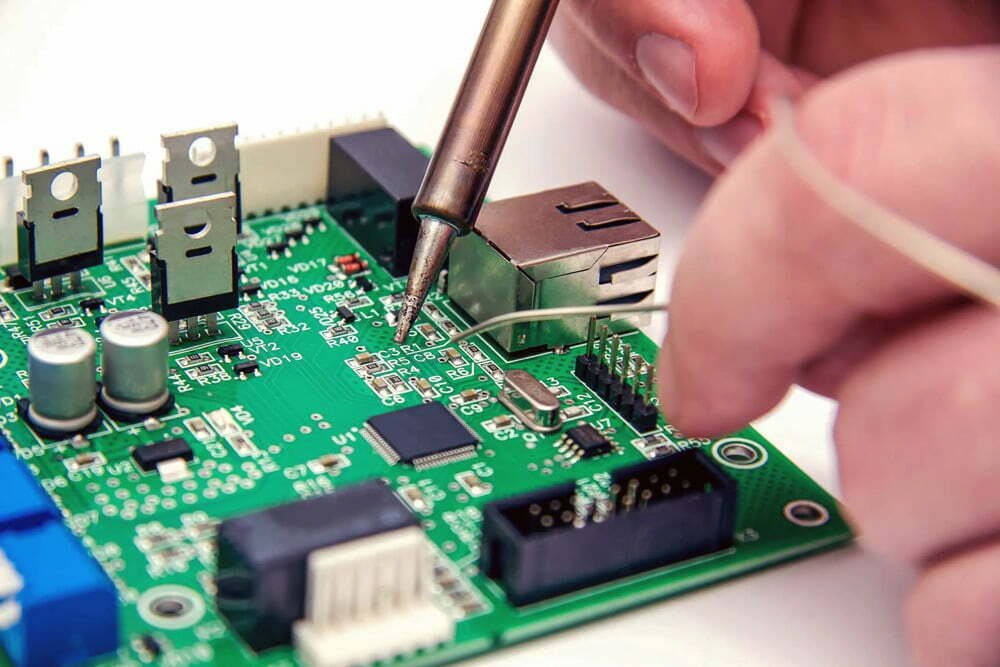

DIP plug-in finished wave soldering

Qualified products will be sent to the DIP plug-in area for the installation of plug-in components.

Our SMT Services

We offer a wide range of services to help your business grow. These include consulting, design, engineering, manufacturing, and surface mount technology assembly.

Our team of experts has extensive experience in SMT and can help you select the right solutions for your specific needs. We work closely with our customers to understand their needs and offer solutions that will increase productivity and profitability.

Fast sample SMT processing

For the SMT processing of incoming samples in the research and development stage, a single BGA represents incoming welding processing, and the entire SMT processing; the quantity is 1-100 pieces, and generally one day delivery (the delivery time depends on the complexity of the specific circuit board) condition).

Small batch SMT processing

The product research and development is completed to prepare for the mass production of the product; the first trial production, the number of incoming samples SMT processing and incoming production of about 101-1000 units; including the single BGA incoming welding processing, the whole board SMT processing ; Generally, it will be delivered within 3-5 working days (the delivery time depends on the complexity of the circuit board).

Medium-volume production SMT processing

The production volume of each batch is not large, but the number of products that need to be completed quickly is 1001-5000 units. We provide fast production speed and undertake the production of incoming samples; including single BGA incoming welding processing, the entire SMT processing ;Generally, it will be delivered within 5-7 working days (the delivery time depends on the complexity of the circuit board).

How to Order SMT from Well Done?

Submit Requirement

Submit your requirement details of pcb assembly on the form, upload your files is available. And we'll reply to you within 24 hours.

Confirm PCB Project

Our expert will contact you for the project details, reply to you with a quotation, and confirm the order after recieving your payment.

Sample Prototype

The sample will be arranged to produce as you expect within 1 day, then we confirm with you the appearance and function.

Delivery Goods

Lead time: At last, your sample w'll be finally shipped to you within 7-15 days. It'll depends the shipping way you choose.

Why Choose Us ?

Full Services

We have the ability to integrate independent R&D design, original factory production and assembly, functional testing and upgrading, as well as batch order.

OEM and ODM

Specializing in OEM and ODM production, as well as EMS contract manufacturing services of electronic products, with strong supporting processing and production capacity.

Advanced Equipments

We have a fully automatic multi-function chip packaging machine, which can mount SMD devices including 0201 and 0402 series, as well as 0.3mm high-precision QFP and BGA equal-pitch chips. And equipped with twelve temperature zone full hot air reflow oven, automatic no-clean spray double wave soldering and automatic solder paste printing machine to ensure the precision and quality of welding.

Professional Team

We have a professional, capable and efficient management and engineering technical team, which can quickly solve various problems in the production process and customer feedback, and ensure continuous and stable product quality.

Explore More Knowledges

Solder Pad Basics: Design & Soldering Tips

Learn solder pad design: size, shape, and thermal relief. Tips to avoid bridging, pad lifting, and improve joint strength. Essential for PCB assembly. Guide here!

HC-SR04 Ultrasonic Sensor Modules

This comprehensive guide is your one – stop resource to explore everything there is to know about the HC-SR04. We’ll start from the very basics,

Counterbore vs Countersink

What is a Counterbore? A counterbore, on the other hand, is a cylindrical hole with a flat bottom, typically consisting of two parts: a larger