What is a Counterbore?

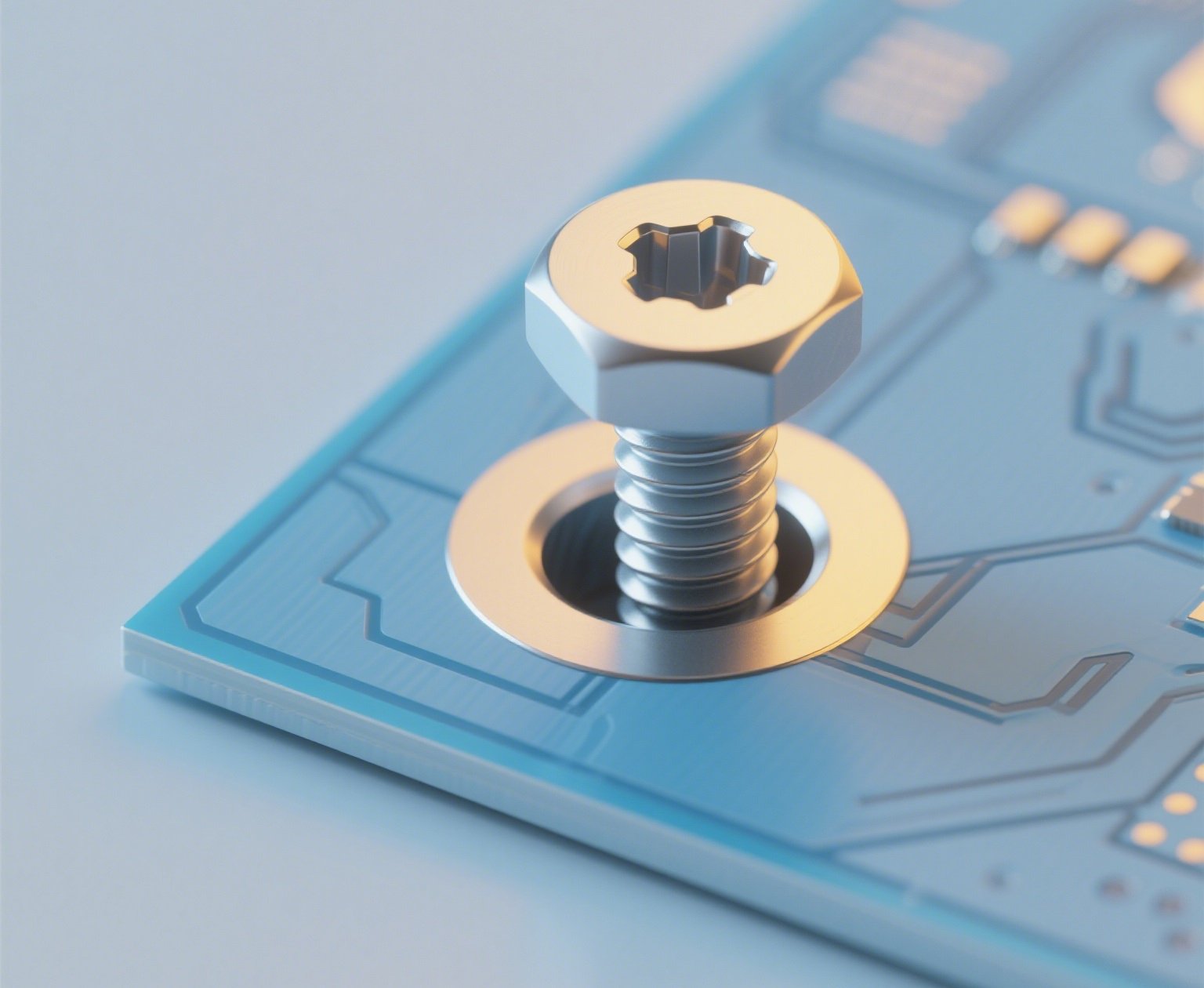

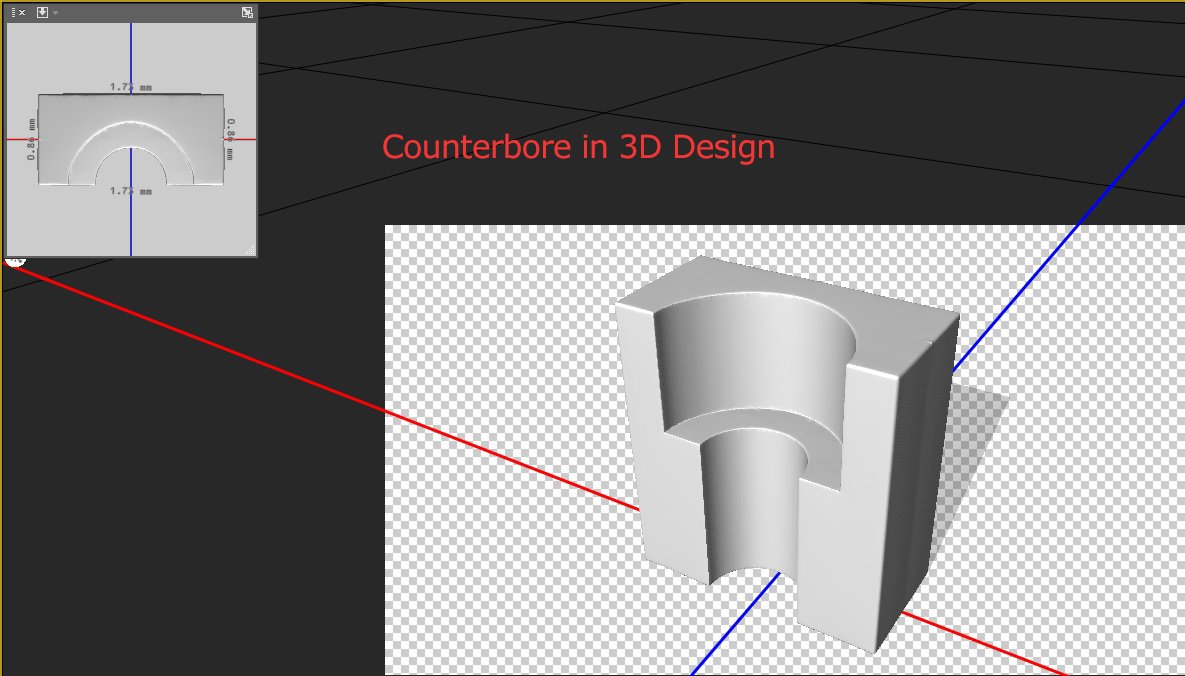

A counterbore, on the other hand, is a cylindrical hole with a flat bottom, typically consisting of two parts: a larger diameter top section and a smaller diameter shaft below. The top section is designed to accommodate the head of a bolt or screw, while the lower shaft fits the shank. This allows the fastener head to be recessed completely within the material, providing a flush surface while distributing the clamping force evenly. Counterbores are essential in mechanical engineering for creating secure, load-bearing connections, especially when using socket-head cap screws or when a precise seating surface is needed for components like washers or bearings.

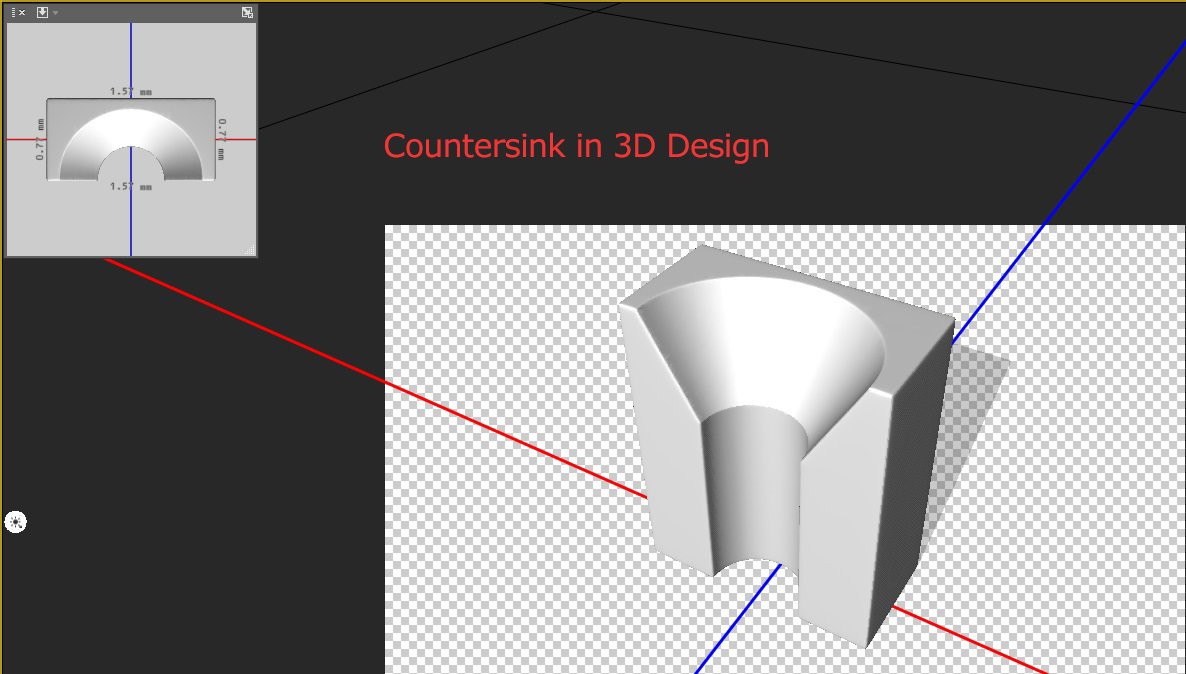

What is a Countersink?

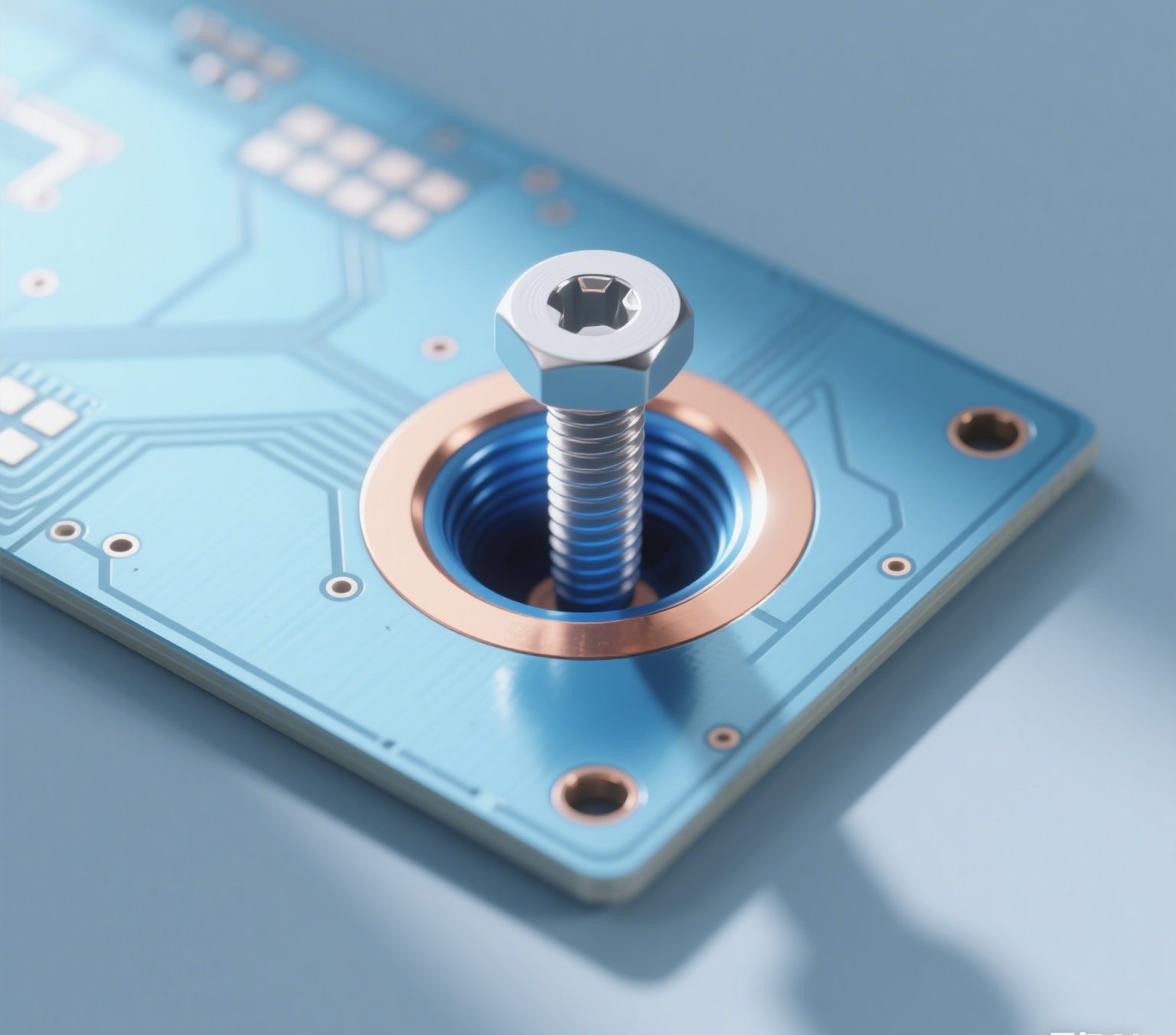

A countersink is a conical-shaped hole designed to allow the head of a flat-head screw or rivet to sit flush with or below the surface of the material. It features a tapered opening that widens from the surface into the material, creating a funnel-like structure. This design is crucial when a smooth, flat surface is required, as it eliminates any protrusion from the fastener head. Common in applications like PCB assembly, furniture, and electronics, countersinks ensure aesthetic appeal and functional flatness, preventing snagging or interference with other components.

Difference Between Counterbore and Countersink

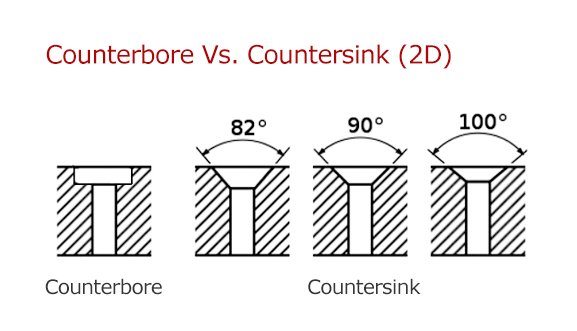

Shape & Structure

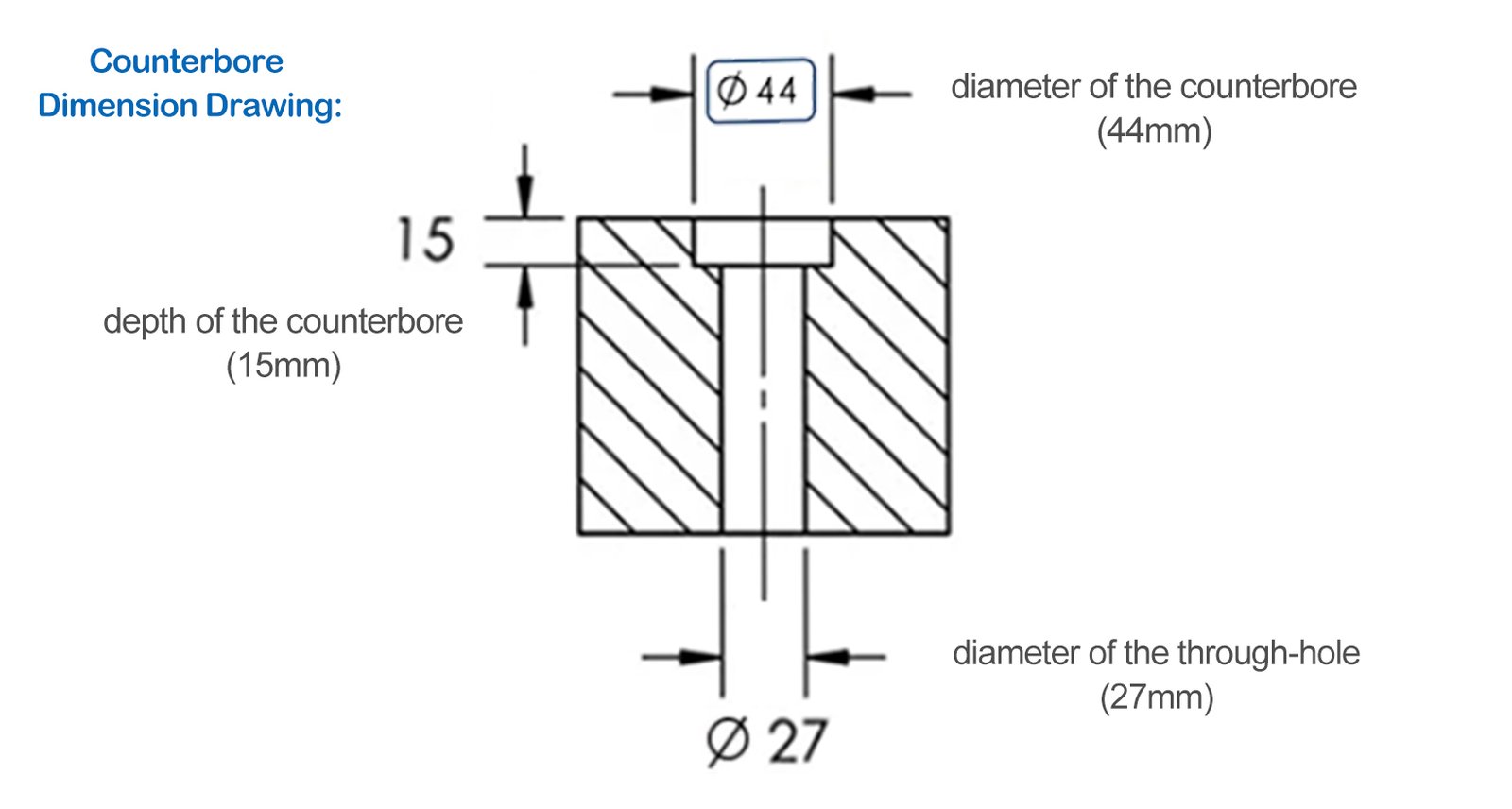

The counterbore features a two-step structure: a cylindrical top portion (the counterbore itself) and a straight shank hole. The cylindrical section has a uniform diameter throughout its depth, with a sharp transition to the smaller diameter shaft, creating a stepped appearance. This design is ideal for accommodating cylindrical fastener heads like socket heads.

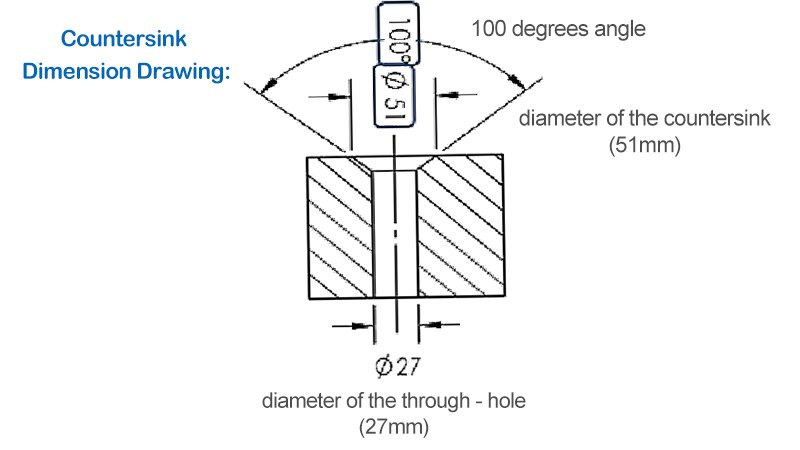

And the countersink is characterized by its conical taper, usually with angles ranging from 60° to 120° (common 82° or 90°), the countersink’s diameter increases as it penetrates the material, forming a symmetrical funnel. This taper matches the angle of flat-head fasteners, ensuring they sit flush.

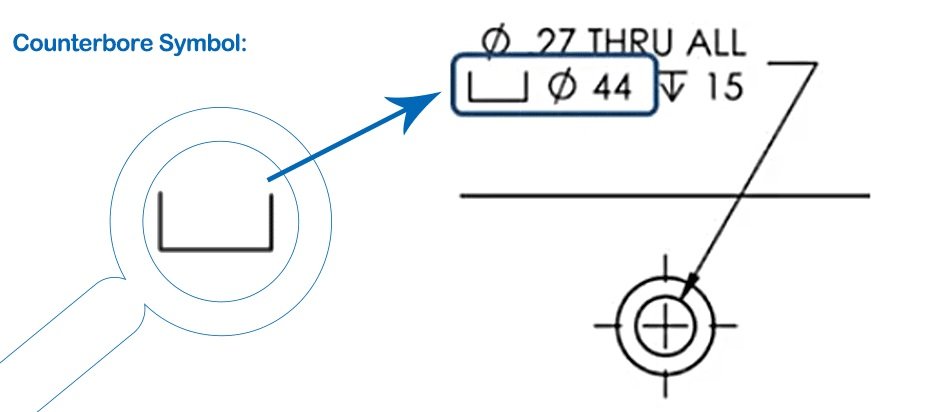

Dimensioning & Symbols

Counterbore is represented with a cylindrical symbol, often denoted by a diameter dimension for the top hole and the shaft, e.g., “∅44 deep 15mm over ∅27” specifies a 44mm diameter top hole, 15mm deep, over a 27mm shaft hole.

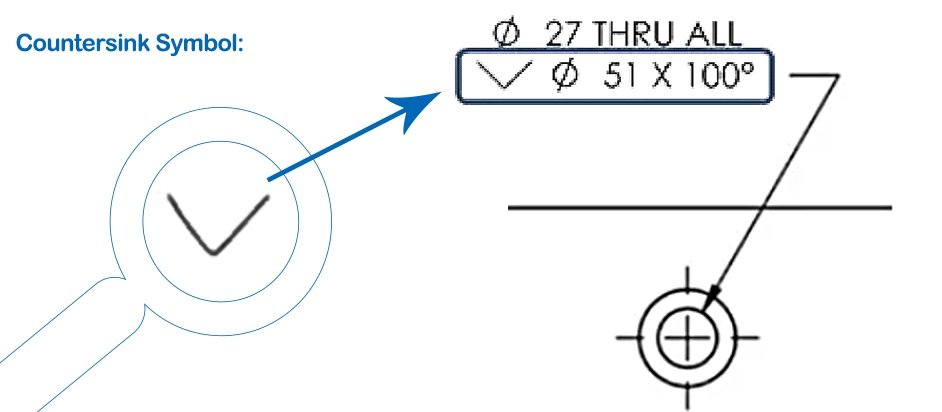

Countersink comes with a conical symbol (a V-shape) before the diameter, followed by the angle, e.g., “V∅51×100°” indicates a 51mm diameter countersink with a 100° angle.

Applications

For Counterbore

- Mechanical Engineering:

Essential for securing machinery parts with socket-head cap screws, providing a stable base for high-load applications like engine mounts or heavy equipment. - Assembly with Washers:

When using flat washers under the fastener head to distribute pressure, the counterbore provides the necessary space for the washer to sit flush. - PCB Mounting with Hardware:

Used to recess standoffs or spacers, ensuring they are securely fastened without protruding and interfering with other components on the board.

For Countersink

- PCB Manufacturing:

Used to create flush surfaces for mounting components, reducing overall thickness in compact devices like smartphones or aerospace electronics. - Woodworking and Furniture:

Ensures screws sit flush with the wood surface for a smooth finish, often used in cabinetry and decorative woodworking. - Sheet Metal Fabrication:

Allows rivets or screws to lie flat, important for aerodynamic surfaces in automotive or aircraft parts, or where surface smoothness affects functionality.

Common Misconceptions and FAQs

Can They Be Used Interchangeably?

No, their designs serve different purposes. A countersink won’t properly seat a cylindrical fastener head, and a counterbore will leave a flat-head screw loose due to the lack of taper.

Which is Better for Aesthetics?

Countersink is ideal for flush, smooth surfaces, while counterbore is more functional for structural integrity, though both can be aesthetically appropriate depending on the fastener used.

How to Avoid Common Mistakes?

- Always match the fastener angle to the countersink angle (e.g., 90° screw with 90° countersink).

- For counterbores, ensure the pilot diameter matches the shaft hole to maintain alignment and prevent wobbling during machining.

Conclusion

In summary, countersink and counterbore are essential tools in precision engineering, each tailored to specific needs. Countersink excels in creating flush, aesthetic surfaces with flat-head fasteners, while counterbore provides robust, load-bearing connections with cylindrical-headed fasteners. By understanding their structural differences, applications, and selection criteria, you can ensure optimal performance and design in your projects, whether in PCB assembly, mechanical engineering, or woodworking.