About Us

Founded in 2008, Shenzhen Well Done PCB company is engaged in PCB reverse engineering technology research service, such as PCB design, bom analysis, PCB manufacturing, chip decryption, PCBA, product evaluation, technical debugging, system software reverse research, hardware reverse research and guidance.

Since 2008

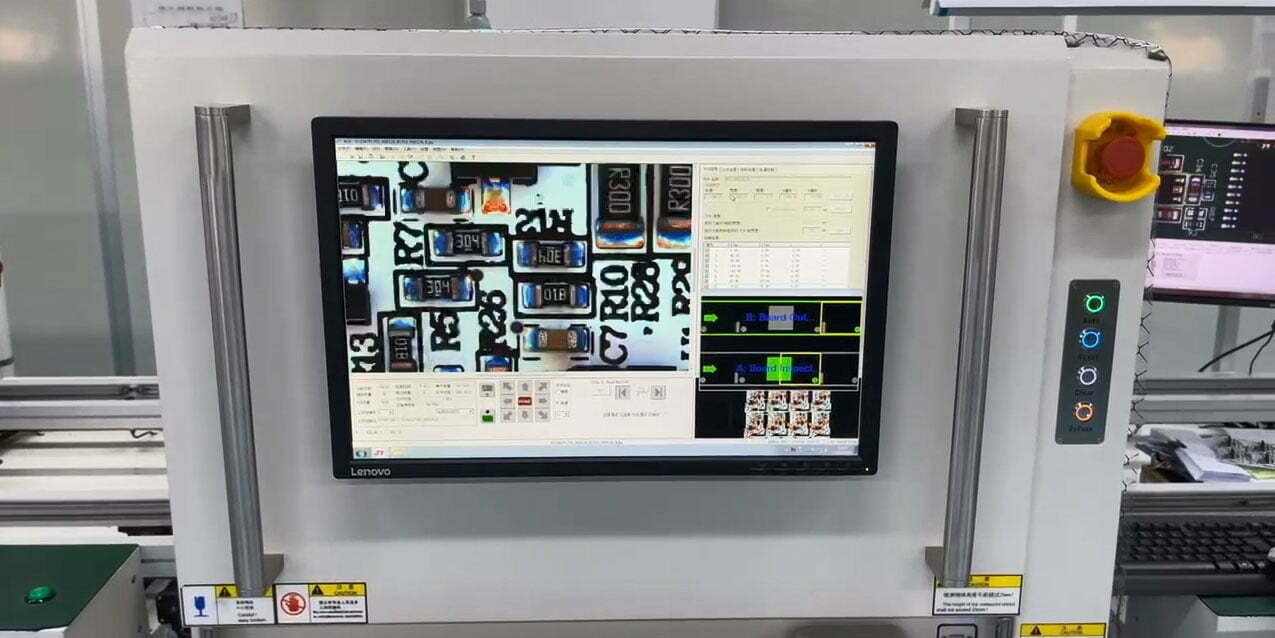

As one of the best pcb layout design companies, we have been focusing on the design and development of hardware, software and drivers in the PCB service industry, and have accumulated rich practical experience in product development, OEM/ODM processing and functional testing.

We have many successful cases, especially in the construction of quality control and comprehensive scientific development management system, technical research, technical analysis and implementation, and reverse research of software and hardware products and their functional modules.

Want to Achieve Your PCB Requirements?

We have rich practical experience in technical research of new products, quality control and construction of a comprehensive scientific development management system, technical research, technical analysis and implementation of information technology software and hardware products and their functional modules, and reverse research.

Well Done PCB Company

Capability

Advantage

Application field

We Will Help You Every Step Of The Way

what do you need?

We Work Hard in Full PCB Services

No matter how difficult your PCB project is, we can tailor and customize it for you, including rewriting software, decrypting chips, designing hardware, solving the technical property rights and technical patents contained in the product itself, etc. The following are specific solutions .

PCB Design

Chip Decrypt

PCB Manufacturing

Software reverse development

PCB Process

Mold shape reverse development

PCB Prototyping

Reverse development of components

Questions And Answers

important things you should know

1: PayPal

2: Wire transfer

3: Western Union

4: T/T

Small as 3.75*2.9mm 4-layer precision circuit board of a certain product, as large as complex 28-layer circuit board.

This price includes all parts of the process including designing, ordering, and managing production run costs. In most cases it’s calculated per unit that can be made from a design or in some cases as an hourly rate for project management functions like changes to designs or order fulfillment at manufacturing facilities.

A PCB can be electroplated by immersing it in a suitable electrolytic bath containing an appropriately chosen solution. The current used to plate the circuit board is usually supplied from a DC power source and will depend on how much surface area needs plating.

Once immersed, the components are contacted with this electrical current which then creates metallic deposits within their structure at each point where there is contact between two dissimilar metals (such as copper and gold).