Modbus Development Services

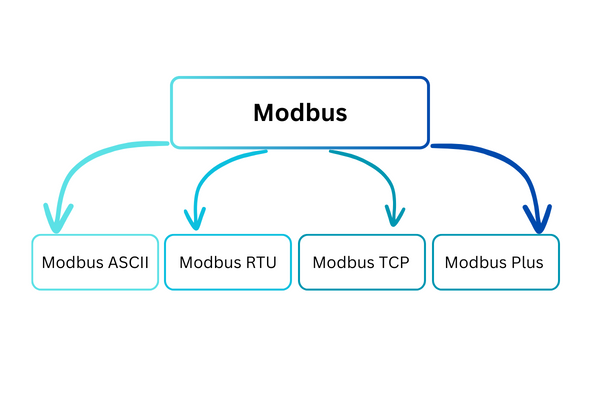

Introduction to Modbus

In the communication between our microcontrollers, as well as between microcontrollers and PCs, different content specifications are established. Both parties involved in the communication need to adhere to these specifications to facilitate effective communication. There are various protocols to meet different device and communication requirements, such as I2C, SPI, UART, etc. Modbus is one such serial communication protocol. It has become an industry standard in communication protocols for the industrial sector and is commonly used for connecting industrial electronic devices. Modbus plays a crucial role in facilitating communication among various devices in industrial environments, such as PLCs, sensors, and actuators.

Benefits & Features of Modbus Module

Our BLDC (Brushless DC) motor solutions offer advanced and efficient solutions for various applications requiring precise motor control and high reliability.

Benefits:

- Seamless interoperability: Modbus allows different devices from different manufacturers to communicate effectively.

- Robustness and reliability: Modbus is known for its simplicity and stability, making it suitable for mission-critical applications.

- Cost-effectiveness: Developing Modbus modules can help streamline industrial processes and reduce overall operational costs.

Features:

- Support for Modbus RTU and Modbus TCP protocols.

- Compatibility with various data types, such as integers, floats, and strings.

- Configurable baud rates, addressing modes, and parity settings.

- Integration with different hardware platforms and operating systems.

Support Extended Interface

Boost Product on Market

Latency less than 10ms

Integrated Multi-devices

Applications of Modbus Module

Due to the mature communication protocol, strong compatibility, ease of implementation, and maintenance, the Modbus module is widely used in various devices as show below:

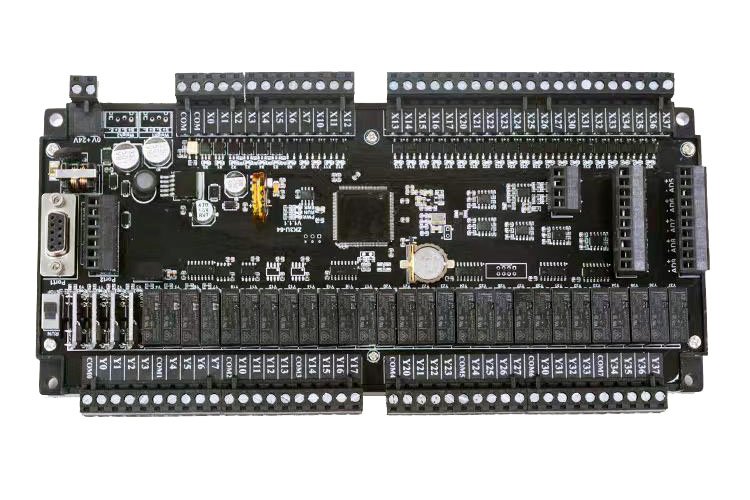

PLC Devices

Remote data acquisition IO modules that support the Modbus RTU protocol can collect data from PLC devices from manufacturers such as Siemens, Mitsubishi, Omron, Schneider, Delta, and Huichuan, enabling communication with these devices.

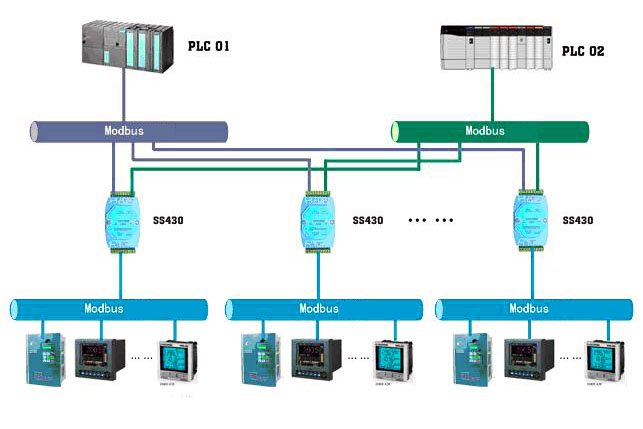

Industrial Automation Devices

The Modbus module plays a crucial role in industrial automation control systems, connecting devices such as PLCs, sensors, and actuators to enable monitoring and control functions. For instance, it can be used to read sensor data such as temperature, pressure, and flow rate

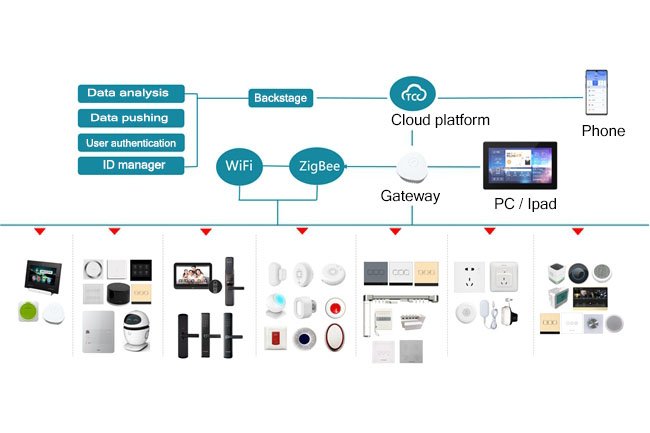

Smart Home Devices

In smart home systems, the Modbus module can connect various sensors and actuators, such as smart bulbs, smart curtains, and security systems, enabling remote control and automated operations.

Energy Monitoring Devices

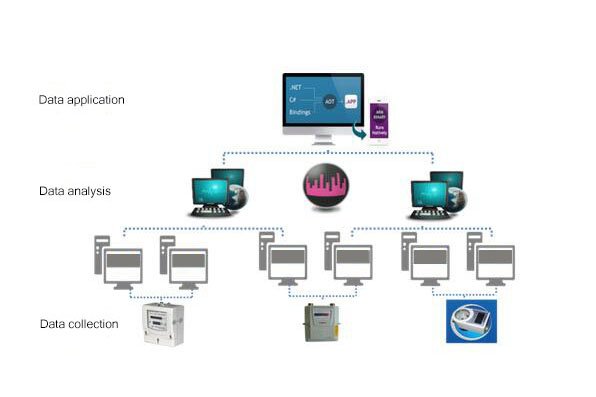

The Modbus protocol can also be used in energy monitoring systems to connect meters for electricity, gas, and water, allowing for the collection and analysis of energy data to help users better manage and conserve resources.

IoT Platform Devices

The Modbus module can serve as a fundamental component of IoT platforms, interacting with other IoT devices for data exchange, collection, processing, and analysis. Additionally, it can act as an edge computing node on the IoT platform, processing and forwarding received data.

Development Tools & Process

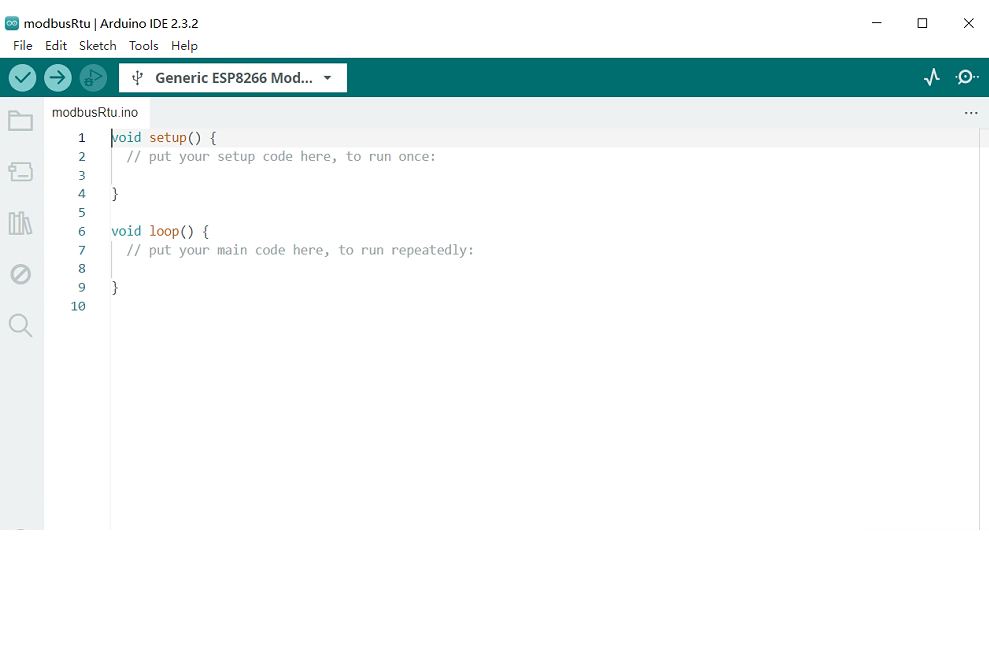

Arduino IDE

Arduino IDE is a powerful tool for Modbus module development. It provides an intuitive interface and support for multiple programming languages, allowing developers to easily write, compile and upload code. The IDE contains rich libraries and functions to quickly implement Modbus communication functions. In addition, it is compatible with a variety of Arduino development boards. In addtion, it also provides debugging functions.

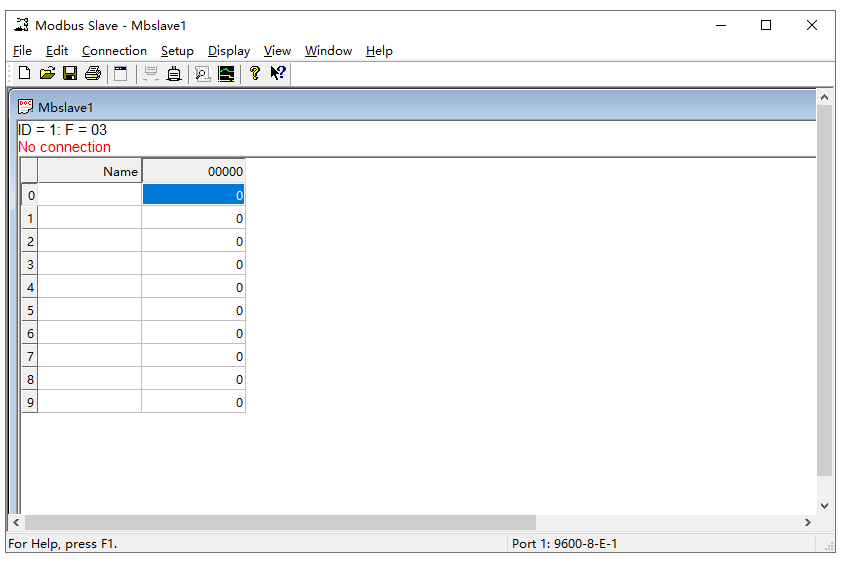

Modbus Slave

The Modbus Slave software is primarily used for simulating Modbus slave or Modbus server devices, receiving command packets from the master station, and sending back data packets. It can simulate up to 32 slave devices/address domains. Each interface provides OLE automation support for Excel reports. Similar to the user interface of Modbus Poll, it supports functions 01, 02, 03, 04, 05, 06, 15, 16, 22, and 23, and monitors serial port data.

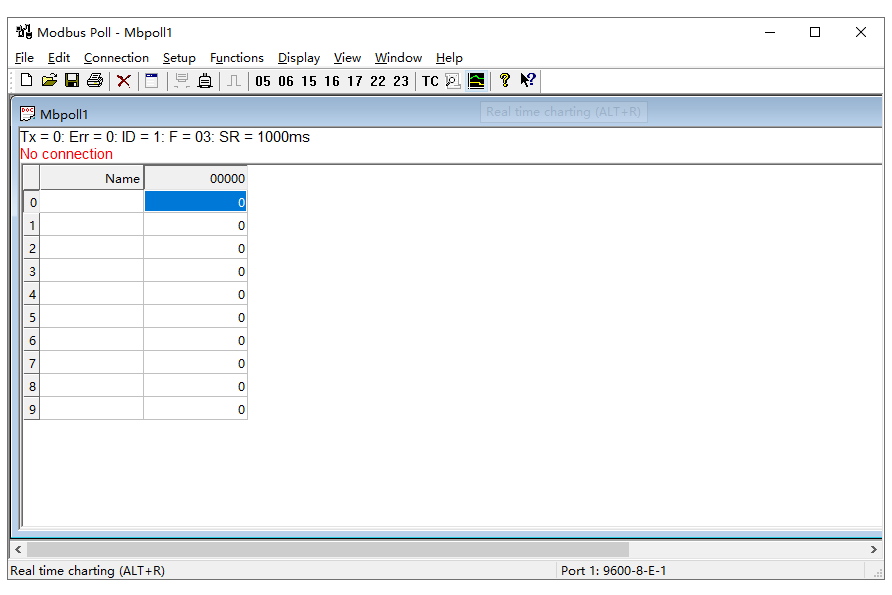

Modbus Poll

"Modbus Poll" is a PC software that simulates a Modbus protocol master, primarily used for emulating the communication process with other slave devices for testing purposes. This software encapsulates a standard Modbus protocol stack internally and provides a user-friendly graphical interface for ease of operation. Currently, the software supports functions such as detecting exception messages, viewing raw messages, and recording data.

Development Process:

Hardware selection

Choose suitable microcontrollers, communication interfaces, and other components.

Software development

Write firmware or software code to implement Modbus communication protocols.

Testing and validation

Conduct thorough testing to ensure compatibility and reliability.

Documentation and deployment

Prepare user manuals, datasheets, and application notes for customers.

Modbus Development Capabilities

Here are detailed technical specifications of our Modbus modules, including:

| Specification | Details |

|---|---|

| Supported Baud Rates | 9600, 19200, 38400 |

| Voltage Levels | 5V, 3.3V |

| Input/Output Options | Digital inputs, Analog outputs |

| Compatibility | Modbus RTU, Modbus TCP/IP |

| Electrical Interfaces | RS232, RS485, TCP/IP |

| Transmission Media | Twisted pair cables, Fiber optics, Infrared, Wireless |

| Modbus Protocol Types | ASCII, RTU, TCP |

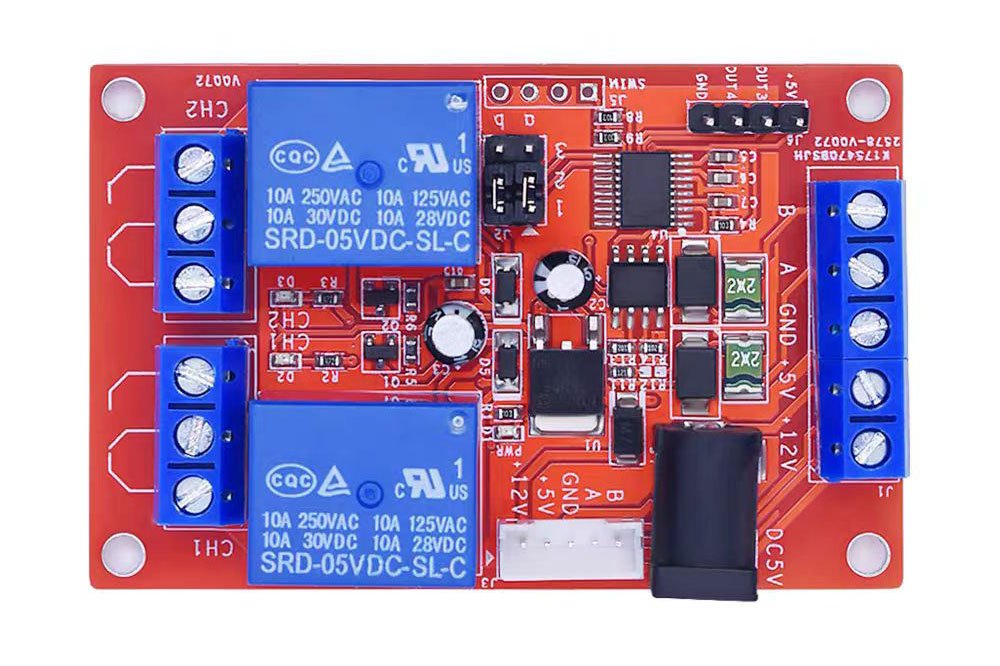

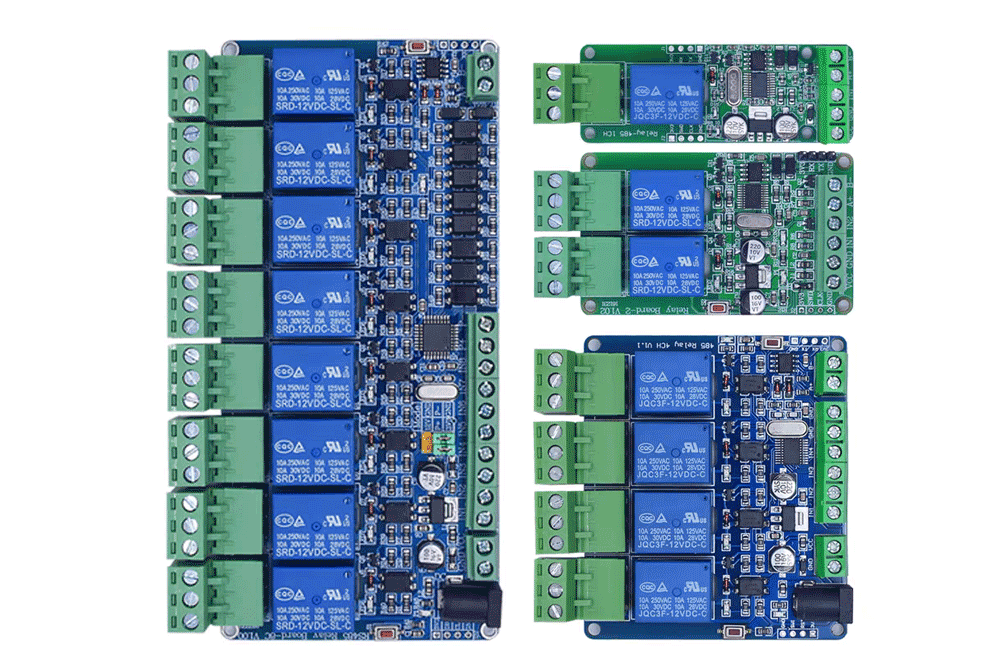

Our Modbus Module Development Case

XH-4020A Industrial Pump Control 28VDC 11 Channels Modbus-RTU

| Interface Parameters | |

|---|---|

| Bus Protocol | Modbus RTU |

| I/O Stations | 64 |

| Data Transmission Medium | RS485 Cable |

| Bus Connection | Terminal Blocks |

| Transmission Rate | 19200 bps |

| Transmission Distance | ≤1200m (station to station) |

| Technical Parameters | |

|---|---|

| Power Supply | 12~24 VDC |

| Weight | Approx. 200g |

| Size | 1209035mm |

| Protection Level | IP65 |

| Operating Temperature | -20~+70°C |

| Storage Temperature | -40~+85°C |

| Relative Humidity | 85%, no condensation |

| Power Connection Method | Socket |

| Configuration Method | Via PLC programming software |

| Digital Output | |

|---|---|

| Rated Voltage | 24VDC (±10%) |

| Signal Points | 32 |

| Signal Type | NPN |

| Load Type | Resistive Load |

| Single Channel Rated Current | Max: 1A |

| Port Protection | Overvoltage, Overcurrent Protection |

| Isolation Voltage | 1000V |

| Channel Indicator Light | Red LED Light |

| Isolation Method | Electromagnetic Isolation |

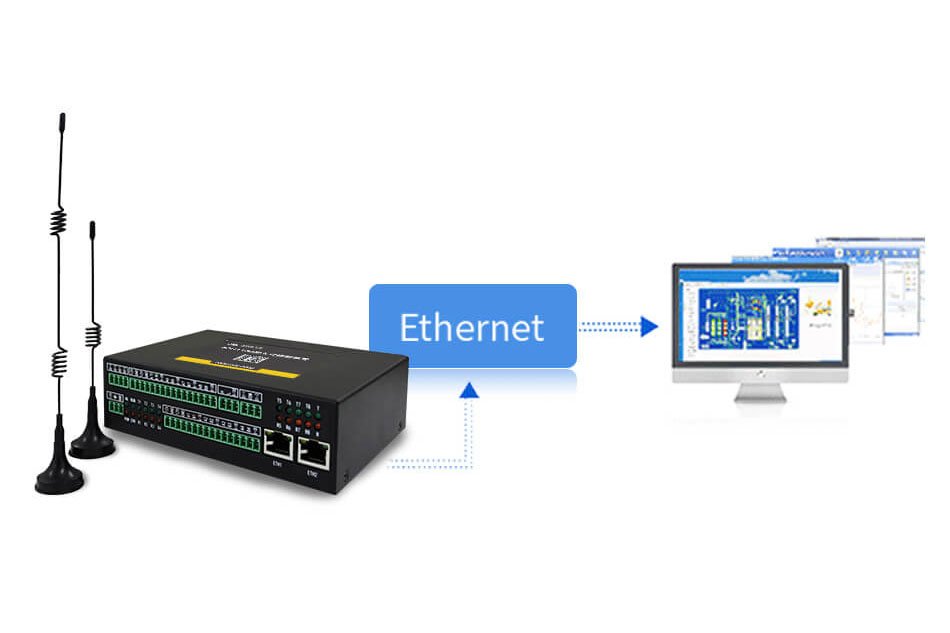

ELT-2000B Agricultural Soil Moisture Monitoring 12V 8 Inputs Modbus-TCP

| Interface Parameters | |

|---|---|

| Bus Protocol | Modbus TCP |

| I/O Stations | 256 |

| Data Transmission Medium | Fiber Optic |

| Bus Connection | SC connectors |

| Transmission Rate | 1 Gb/s |

| Transmission Distance | ≤2 km (station to station) |

| Technical Parameters | |

|---|---|

| Power Supply | 24~48 VDC |

| Weight | Approx. 500g |

| Size | 180*120*45mm |

| Protection Level | IP67 |

| Operating Temperature | -40~+85°C |

| Storage Temperature | -50~+90°C |

| Relative Humidity | 90%, no condensation |

| Power Connection Method | Terminal blocks |

| Configuration Method | Via SCADA software |

| Digital Output | |

|---|---|

| Rated Voltage | 24VDC (±15%) |

| Signal Points | 64 |

| Signal Type | PNP |

| Load Type | Inductive Load |

| Single Channel Rated Current | Max: 2A |

| Port Protection | Overvoltage, Overcurrent Protection |

| Isolation Voltage | 1500V |

| Channel Indicator Light | Yellow LED Light |

| Isolation Method | Optical Coupling Isolation |

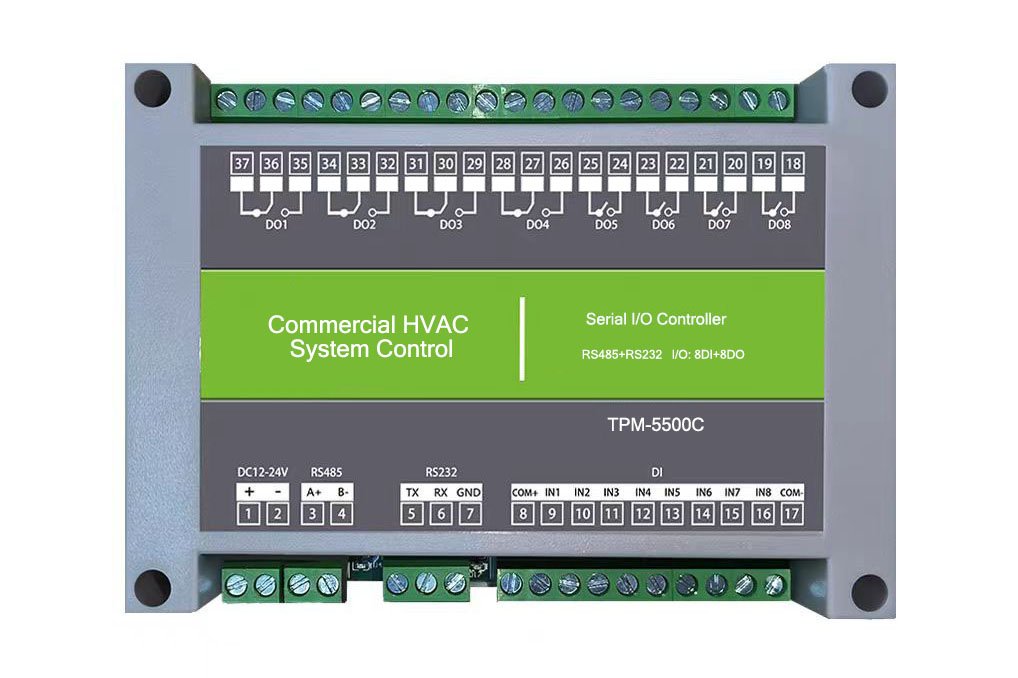

TPM-5500C Commercial HVAC System Control 24V RS485&232 Modbus-RTU

| Interface Parameters | |

|---|---|

| Bus Protocol | Modbus RTU |

| I/O Stations | 32 |

| Data Transmission Medium | Wireless (Zigbee) |

| Bus Connection | Terminal blocks |

| Transmission Rate | 115200 bps |

| Transmission Distance | ≤100m (station to station) |

| Technical Parameters | |

|---|---|

| Power Supply | 48~60 VDC |

| Weight | Approx. 150g |

| Size | 150*100*30mm |

| Protection Level | IP54 |

| Operating Temperature | -10~+60°C |

| Storage Temperature | -30~+80°C |

| Relative Humidity | 80%, no condensation |

| Power Connection Method | Socket |

| Configuration Method | Via HMI Panel |

| Digital Output | |

|---|---|

| Rated Voltage | 24VDC (±20%) |

| Signal Points | 16 |

| Signal Type | Opto-Isolated |

| Load Type | Capacitive Load |

| Single Channel Rated Current | Max: 1.5A |

| Port Protection | Overvoltage, Overcurrent Protection |

| Isolation Voltage | 1200V |

| Channel Indicator Light | Blue LED Light |

| Isolation Method | Capacitive Isolation |