Instant Cost Estimator

Estimated Total Cost

$0.00

$0.00 / board

Cost Driver Deep Dive

Each choice you make impacts the final cost. This section explores why certain options are more expensive and helps you make informed trade-offs for your project.

Board Size & Quantity

These are the most significant cost drivers. Larger boards consume more raw material (laminate), and higher quantities benefit from economies of scale. The setup cost (tooling, programming) is fixed, so producing more boards spreads this cost out, lowering the per-unit price.

Number of Layers

Adding layers increases material cost and manufacturing complexity. Each additional pair of layers requires more lamination cycles and precise alignment, significantly raising the potential for defects and thus driving up the price.

Surface Finish

The surface finish protects the exposed copper and provides a solderable surface. Standard HASL is the most cost-effective. Premium finishes like ENIG (Electroless Nickel Immersion Gold) involve more complex chemical processes and precious metals, which increases the cost but offers a flatter surface and longer shelf life, ideal for fine-pitch components.

Visualizing Economies of Scale

How does your per-unit cost change as you order more boards? Use the chart below to see the impact of quantity and board size on your total and per-unit costs. This helps you find the sweet spot for your production run.

Cost-Saving Strategies

Smart design choices can significantly reduce your prototyping expenses. Here are some actionable tips to keep your costs down without sacrificing quality.

Stick to Standard Specs

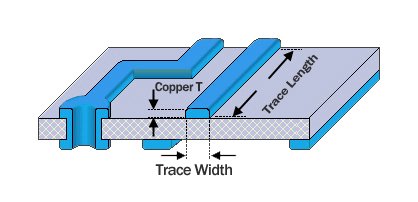

Whenever possible, use standard board thicknesses, copper weights, and trace/space clearances. Custom specifications require special handling and tooling, which adds to the cost.

Panelize Your Boards

If you have multiple small boards, ask your manufacturer to panelize them. This treats multiple designs as one larger board, optimizing material usage and reducing setup costs.

Allow for Longer Lead Times

Rush jobs are expensive. If your project timeline allows, choosing a standard turnaround time is one of the easiest ways to save a significant amount of money.