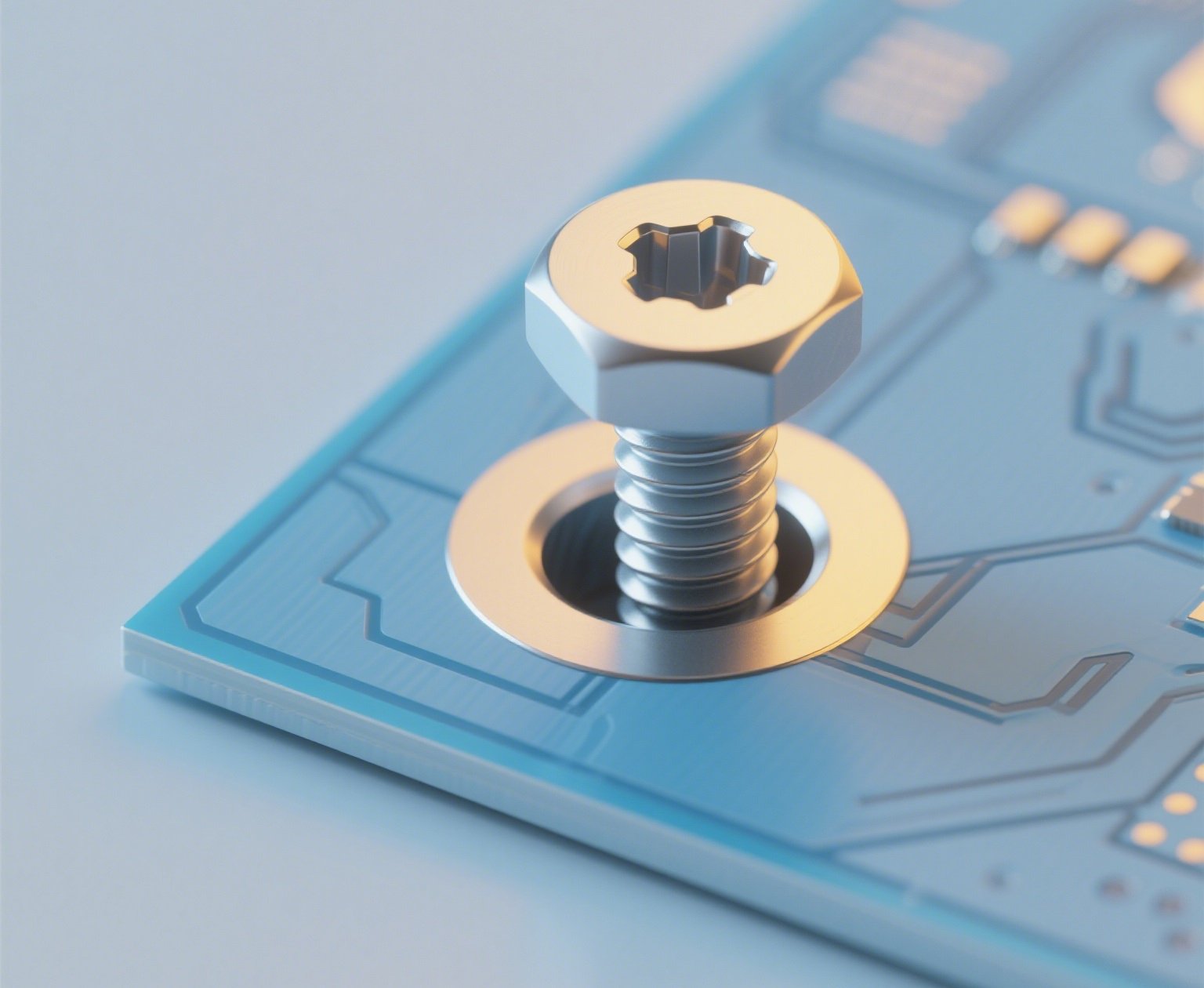

什麼是倒角孔?

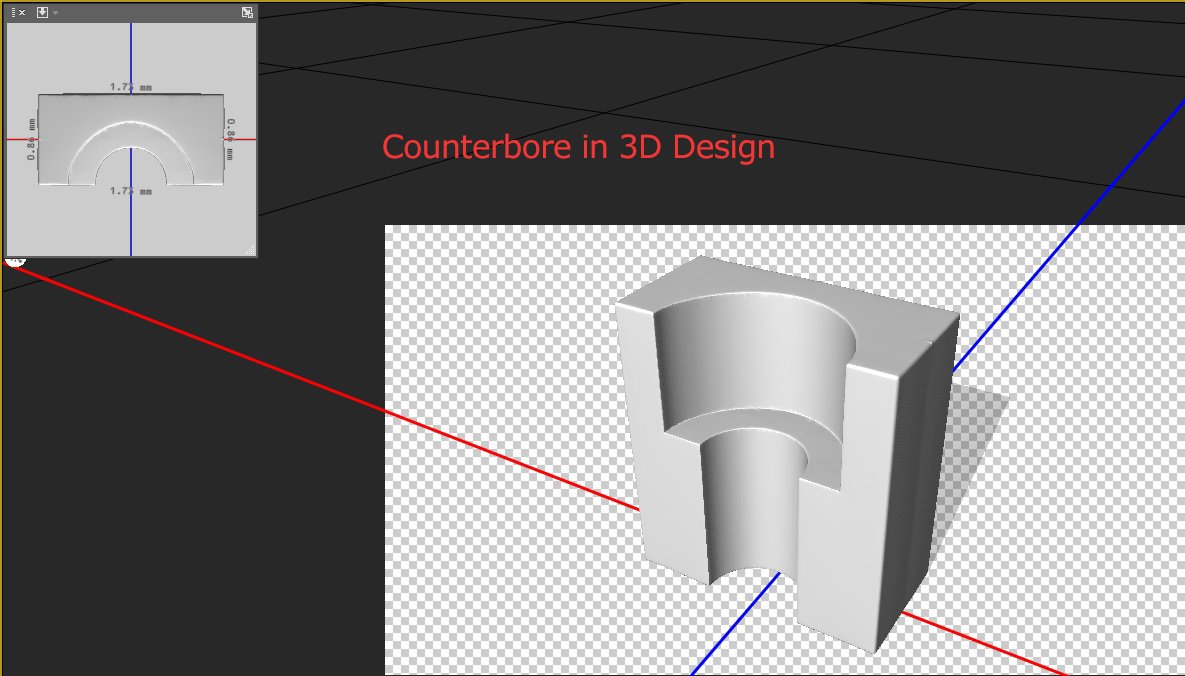

倒角孔是一種圓柱形孔,底部平坦,通常由兩個部分組成:較大的直徑頂部和底下的較小直徑軸。頂部設計用於容納螺栓或螺絲的頭部,而下軸用於配合軸。這使得緊固件的頭部完全嵌入材料中,提供一個平整的表面,同時均勻地分配夾緊力。倒角孔在機械工程中對於創建安全、承載連接至關重要,尤其是在使用六角螺栓或需要組件(如墊圈或軸承)的精確座椅表面時。

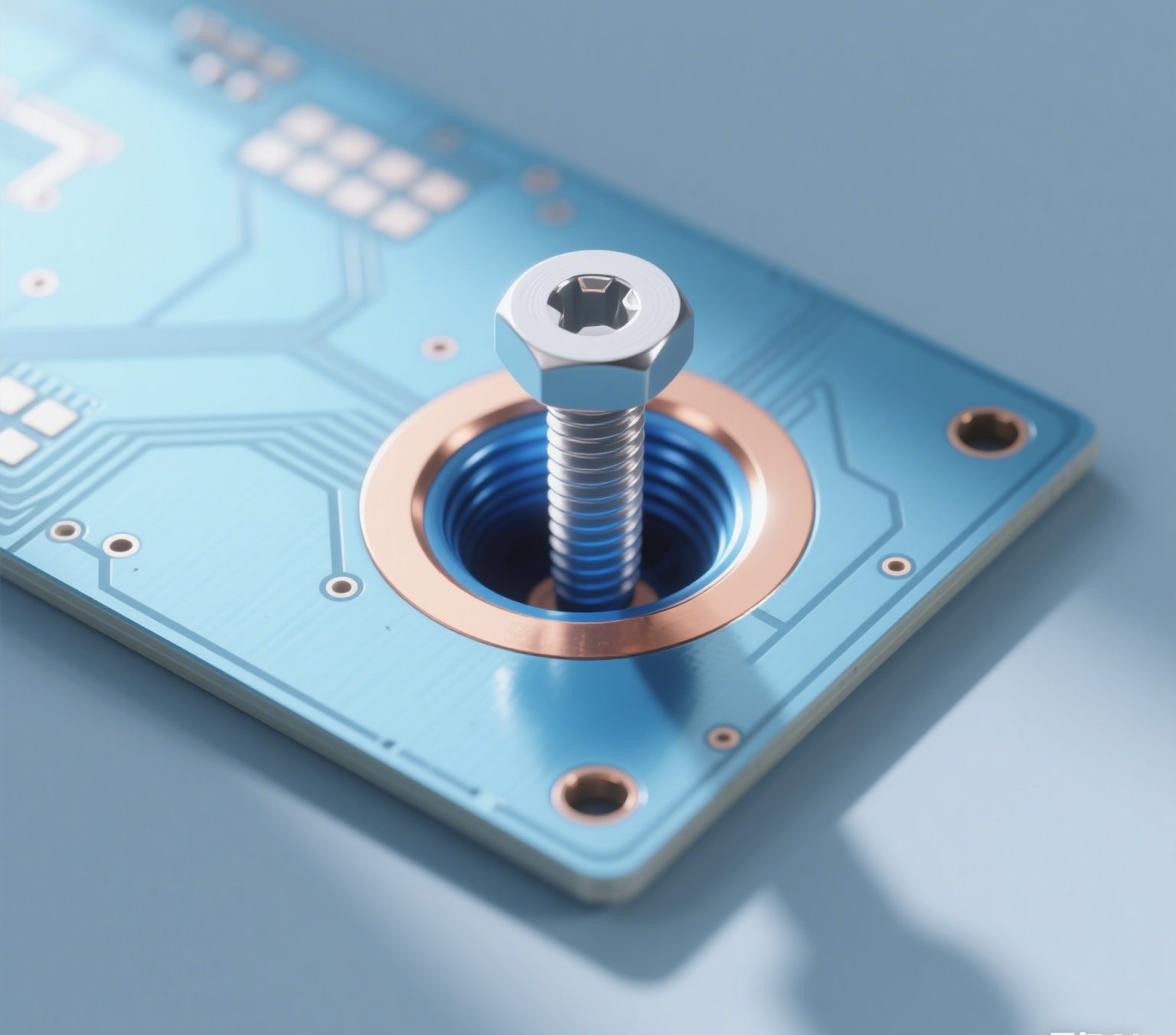

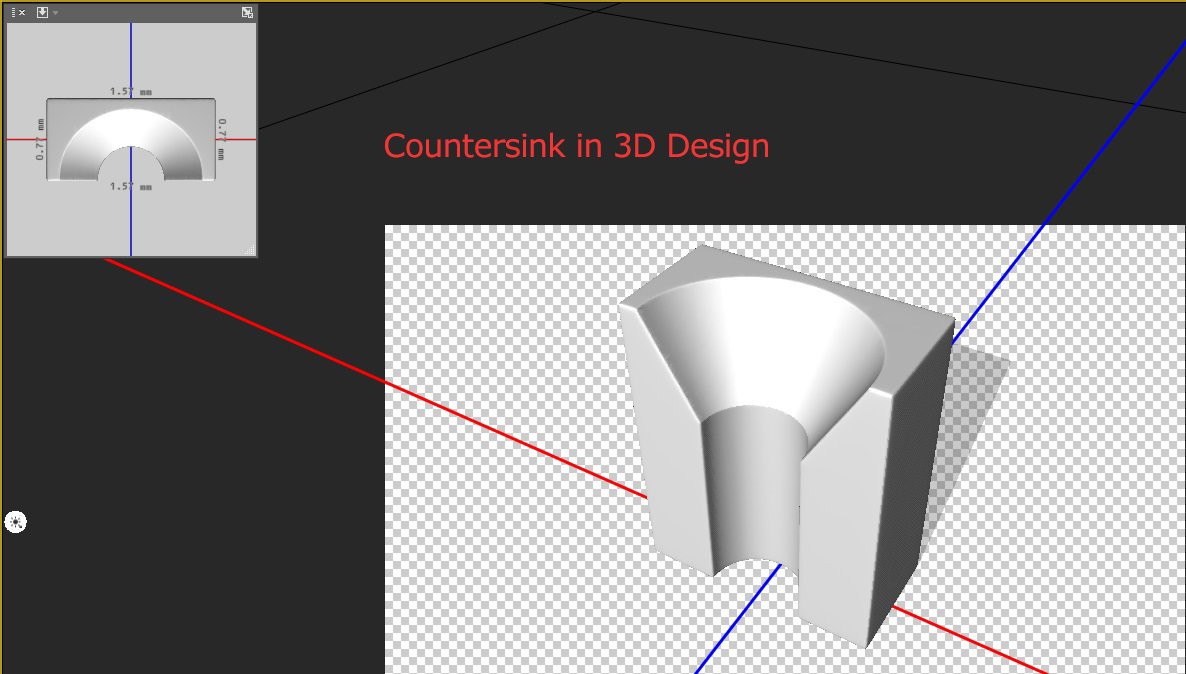

什麼是 Countersink?

Countersink 是一種錐形孔,設計用於允許平頭螺絲或鉚釘的頭部與材料表面齊平或低於材料表面。它具有從表面擴展到材料的漸寬開口,形成漏斗狀結構。此設計對於需要光滑、平坦表面的情況至關重要,因為它消除了緊固件頭部的任何突出。Countersink 常用於 PCB 組裝、家具和電子產品等應用中,確保美觀和功能上的平坦,防止鉤住或與其他組件干擾。

倒角孔和 Countersink 的區別

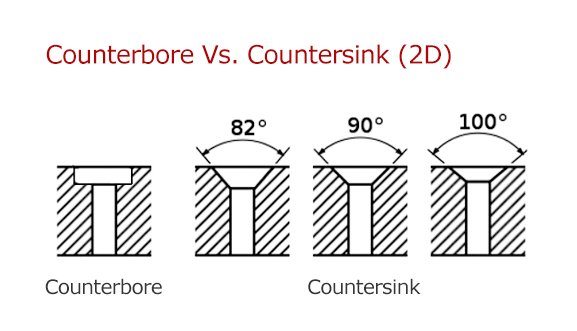

形狀和結構

倒角孔具有兩步結構:圓柱形頂部(倒角孔本身)和直軸孔。圓柱形部分在其深度內具有均勻的直徑,與較小直徑軸之間有一個尖銳的過渡,形成分階外觀。此設計非常適合容納圓柱形緊固件頭部,例如六角頭。

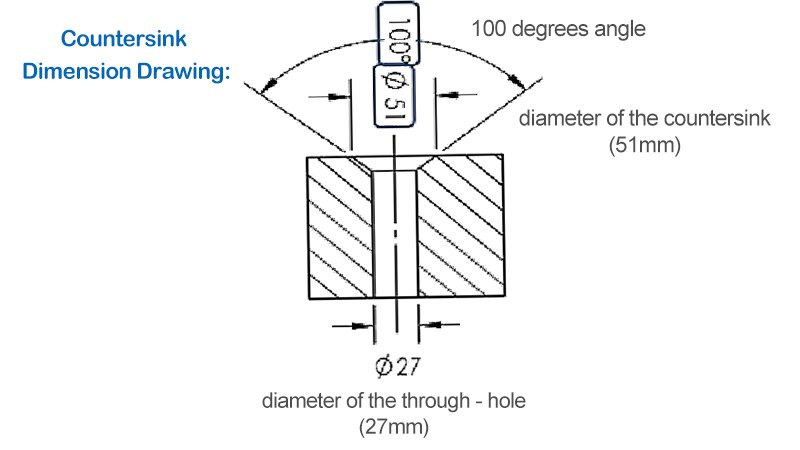

Countersink 的特點是其錐形漸變,通常角度範圍從 60° 到 120°(常見 82° 或 90°),Countersink 的直徑隨著其穿透材料而增加,形成一個對稱的漏斗。這種漸變與平頭緊固件的角度相匹配,確保它們可以齊平地坐好。

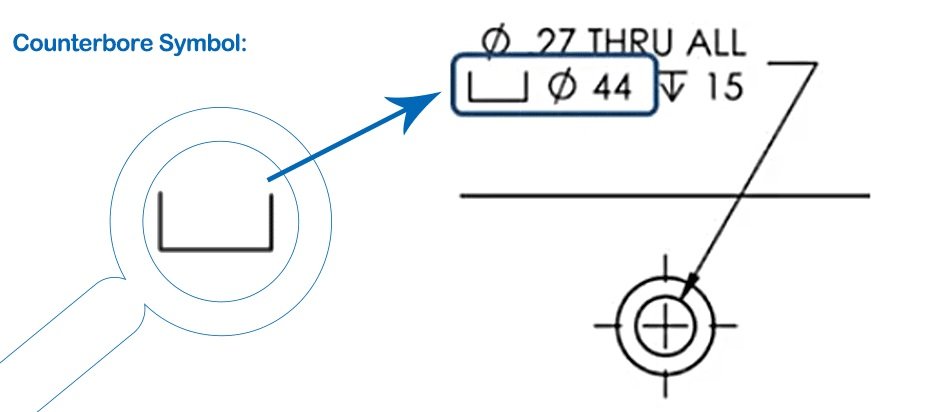

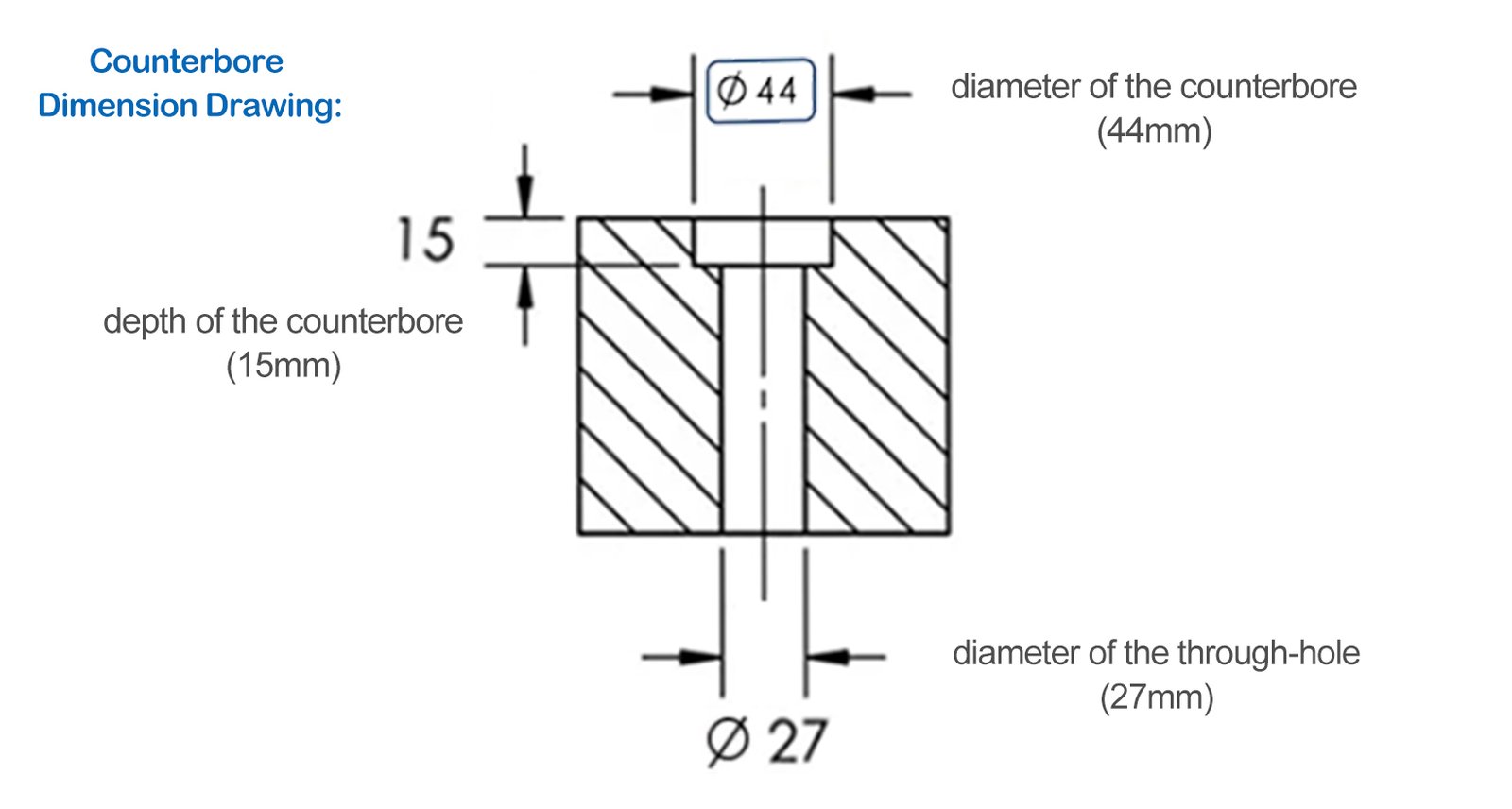

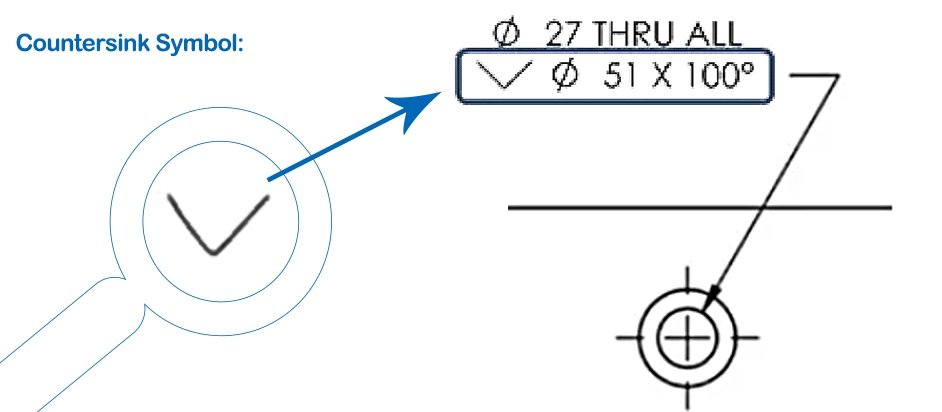

尺寸和符號

倒角孔用圓柱形符號表示,通常標示頂孔的直徑和軸的尺寸,例如“Ø44 深 15mm 覆 Ø27”表示直徑為 44mm 的頂孔,深度為 15mm,覆蓋 27mm 的軸孔。

Countersink 帶有錐形符號(V 形)在直徑之前,然後是角度,例如“VØ51×100°”表示直徑為 51mm 的 Countersink,角度為 100°。

應用

用於倒角孔

- 機械工程:

對於使用六角螺栓固定機械零件至關重要,為高負載應用(如引擎支架或重型設備)提供穩定的基礎。 - 使用墊圈的組裝:

當在緊固件頭部下方使用平墊圈以分配壓力時,倒角孔提供墊圈齊平坐下的必要空間。 - PCB 硬件安裝:

用於嵌入支架或間距器,確保它們牢固地固定,而不會突出並干擾板上的其他組件。

用於 Countersink

- PCB Manufacturing:

Used to create flush surfaces for mounting components, reducing overall thickness in compact devices like smartphones or aerospace electronics. - Woodworking and Furniture:

Ensures screws sit flush with the wood surface for a smooth finish, often used in cabinetry and decorative woodworking. - Sheet Metal Fabrication:

Allows rivets or screws to lie flat, important for aerodynamic surfaces in automotive or aircraft parts, or where surface smoothness affects functionality.

Common Misconceptions and FAQs

Can They Be Used Interchangeably?

No, their designs serve different purposes. A countersink won’t properly seat a cylindrical fastener head, and a counterbore will leave a flat-head screw loose due to the lack of taper.

Which is Better for Aesthetics?

Countersink is ideal for flush, smooth surfaces, while counterbore is more functional for structural integrity, though both can be aesthetically appropriate depending on the fastener used.

How to Avoid Common Mistakes?

- Always match the fastener angle to the countersink angle (e.g., 90° screw with 90° countersink).

- For counterbores, ensure the pilot diameter matches the shaft hole to maintain alignment and prevent wobbling during machining.

Conclusion

In summary, countersink and counterbore are essential tools in precision engineering, each tailored to specific needs. Countersink excels in creating flush, aesthetic surfaces with flat-head fasteners, while counterbore provides robust, load-bearing connections with cylindrical-headed fasteners. By understanding their structural differences, applications, and selection criteria, you can ensure optimal performance and design in your projects, whether in PCB assembly, mechanical engineering, or woodworking.