1. Enter Your Project Specifications

2. Estimated Cost Breakdown

Bare Board Cost:

$0.00

Component Sourcing:

$0.00

Assembly Labor & Stencil:

$0.00

Total Estimated Cost:

$0.00

Cost Per Board:

$0.00

3. Understanding the Factors & How to Save

What Drives Your PCB Assembly Cost?

- Board Type & Complexity: Multilayer boards with fine traces and complex routing are significantly more expensive to fabricate than simple single or double-sided boards. The material (e.g., FR-4, Rogers) also plays a major role.

- Quantity: Economies of scale are huge in PCB manufacturing. The per-unit cost drops dramatically as order quantity increases, as setup costs (tooling, stencils, programming) are amortized over more boards.

- Number of Layers: Each additional layer adds multiple steps to the fabrication process (lamination, drilling, plating), increasing both material cost and labor time.

- Turn Time: Expedited and rush orders require prioritizing your job over others and often running special shifts, which carries a premium charge. Standard turn times offer the most cost-effective option.

- Component Sourcing: The cost of the components themselves is a major factor. Sourcing rare or long-lead-time parts can increase costs and delays. Consigned vs. turnkey kitting also affects the price.

- Assembly Technology: Surface-mount technology (SMT) is generally more automated and cheaper for high volumes. Through-hole assembly often requires more manual labor. A mix of both is the most complex and costly.

Practical Ways to Reduce Assembly Costs

- Increase Your Order Volume: If possible, consolidate smaller orders into a larger batch to take advantage of economies of scale.

- Standardize Components: Use common, readily available parts wherever possible. This reduces sourcing costs and risks of delays. Check supplier stock before finalizing your Bill of Materials (BOM).

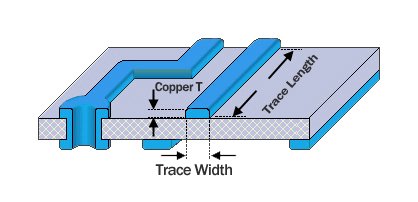

- Optimize Your Design for Manufacturing (DFM): Keep trace widths, spacing, and via sizes within standard manufacturing tolerances. Avoid overly dense layouts or unnecessarily small components which require more precise, expensive machinery.

- Choose a Standard Turn Time: Unless your project is extremely urgent, planning for a standard production schedule will always be your cheapest option.

- Panelize Your Boards: Place multiple copies of a small board design onto a single, larger panel. This streamlines the assembly process, reducing machine setup time and handling per board.